Automatic gas distribution unit and automatic quality control system

An automatic and standard gas technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of cumbersome preparation of instruments and equipment, large volume of gas distribution system, and inability to configure and configure gas, so as to save labor costs and time costs, and ensure The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

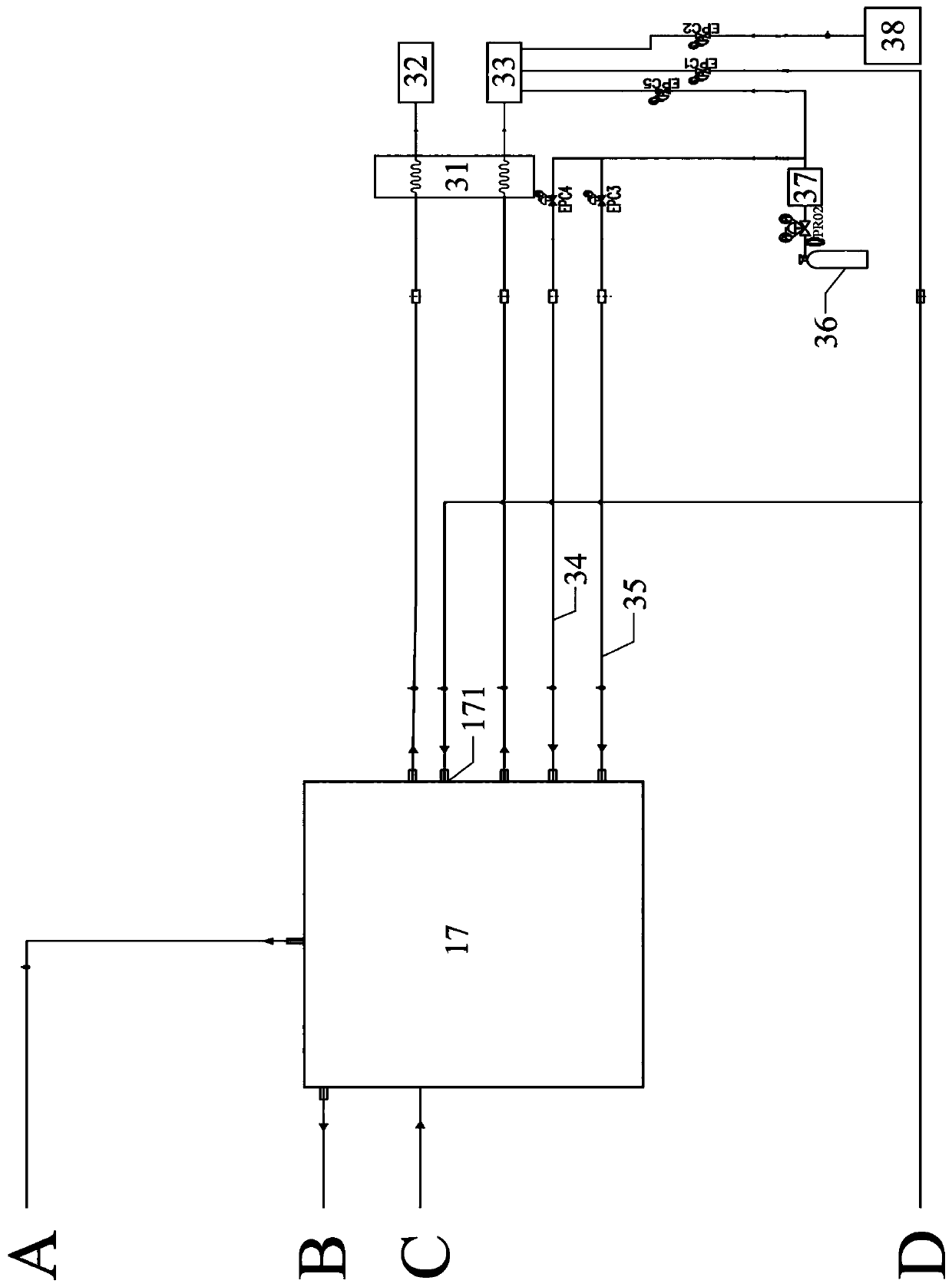

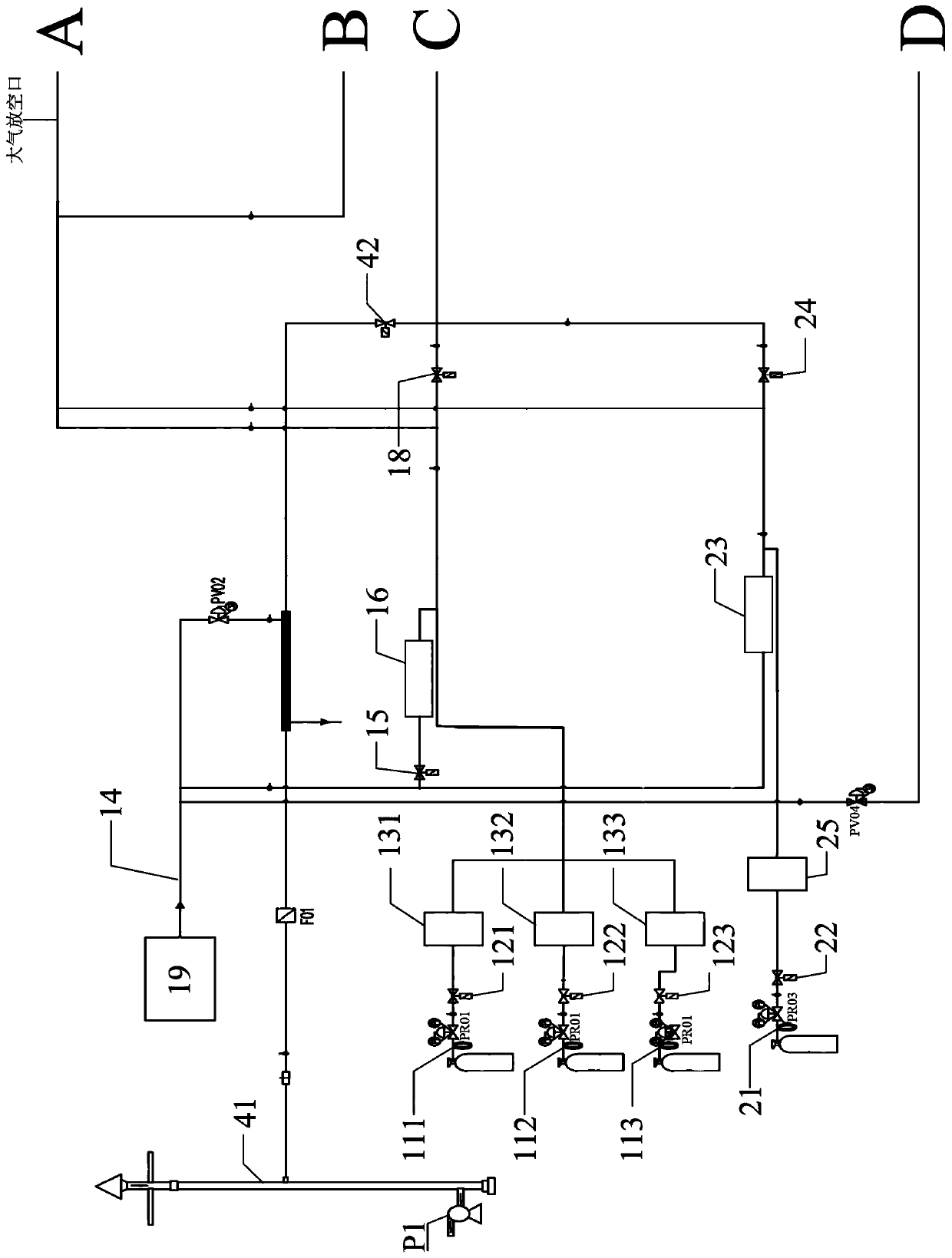

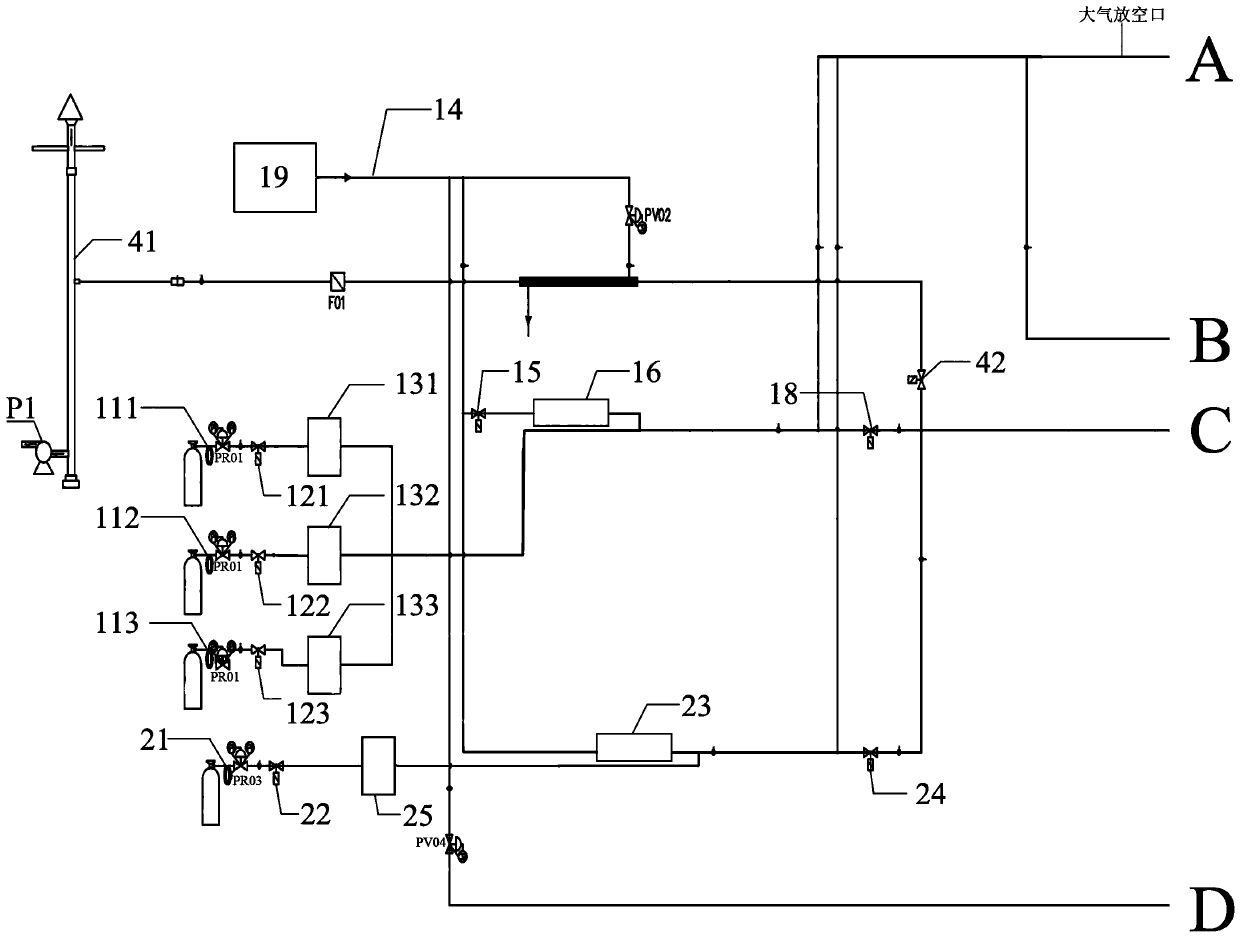

[0046] This embodiment is used to provide an automatic quality control system of the present invention, and the specific structure is as follows figure 1 with figure 2 Shown.

[0047] The automatic quality control system includes: an automatic gas distribution unit 1, a data processing unit (not shown in the figure), an internal standard gas input unit 2, a detection unit 3, and a sampling unit 4.

[0048] Automatic gas distribution unit 1 includes: 3 external standard gas input channels (111, 112, 113), 3 external standard gas solenoid switch valves (121, 122, 123), 3 external standard gas flow controllers (131, 132) , 133), dilution gas input channel 14, dilution gas solenoid switch valve 15, dilution gas flow controller 16, enrichment module 17, solenoid switch valve 18, zero gas generator 19, atmospheric vent and controller (not shown in the figure) Draw). The zero gas generator 19 is connected to the diluent input channel 14, and the diluent electromagnetic switch valve 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com