Automatic monitoring method and system for slumps in concrete production

An automatic monitoring and concrete technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of low monitoring efficiency and achieve the effect of improving work efficiency and production quality, reducing influence and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

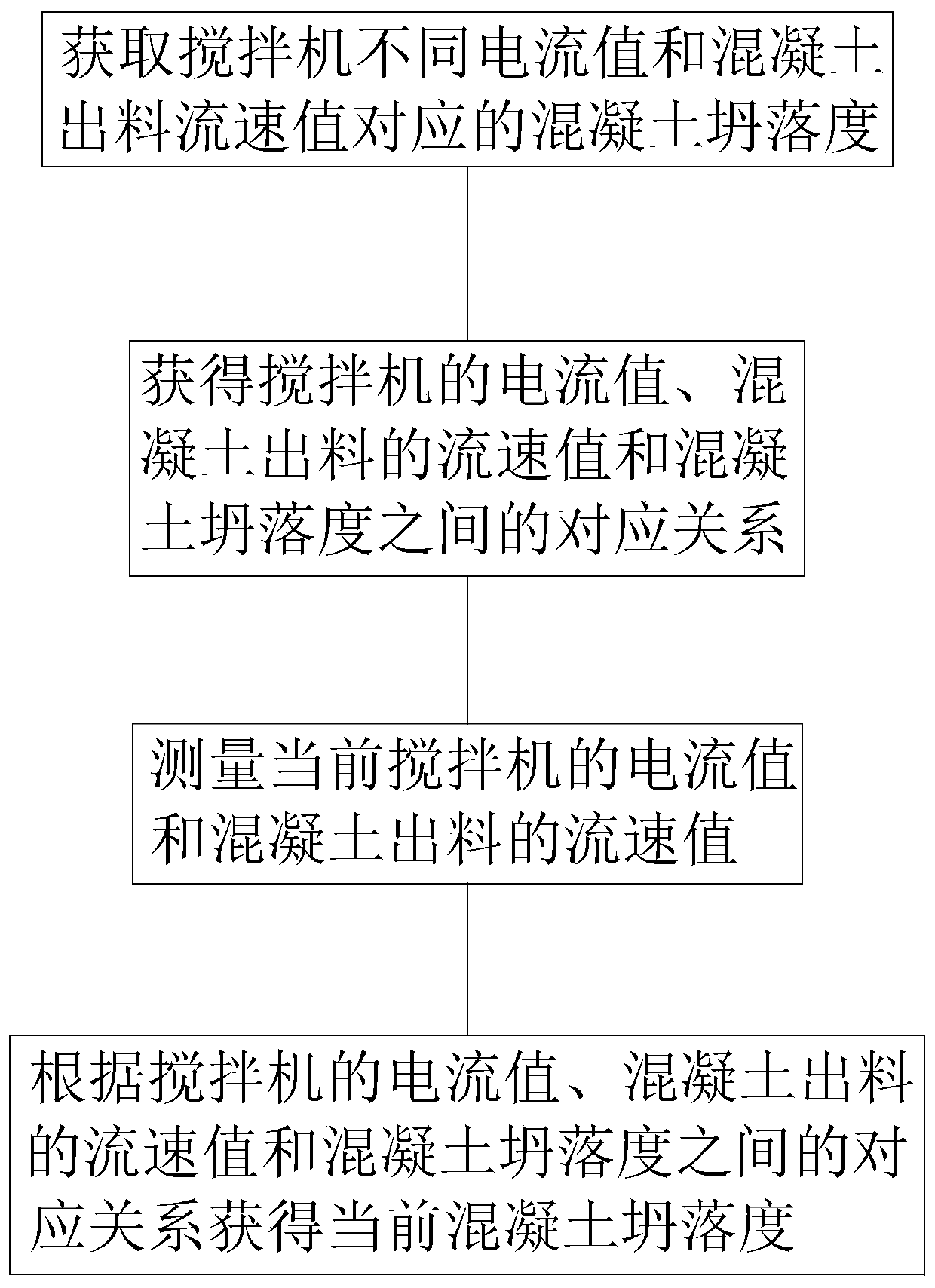

[0044] Embodiment 1: automatic slump monitoring method in concrete production, as figure 1 shown, including the following steps:

[0045] Obtain the concrete slump corresponding to different current values and concrete discharge flow velocity values of the mixer, and obtain the concrete slump corresponding to different current values and concrete discharge flow velocity values of the mixer for different specifications of concrete.

[0046] Obtain the correspondence between the current value of the mixer, the flow velocity value of the concrete discharge and the concrete slump, and obtain the current value of the mixer, the flow velocity value of the concrete discharge and the concrete slump for different specifications of concrete. Correspondence.

[0047] When the outlet of the mixing drum is opened for discharging, measure the current value of the current mixer and the flow rate of the concrete at the outlet of the mixing drum.

[0048] The current concrete slump i...

Embodiment 2

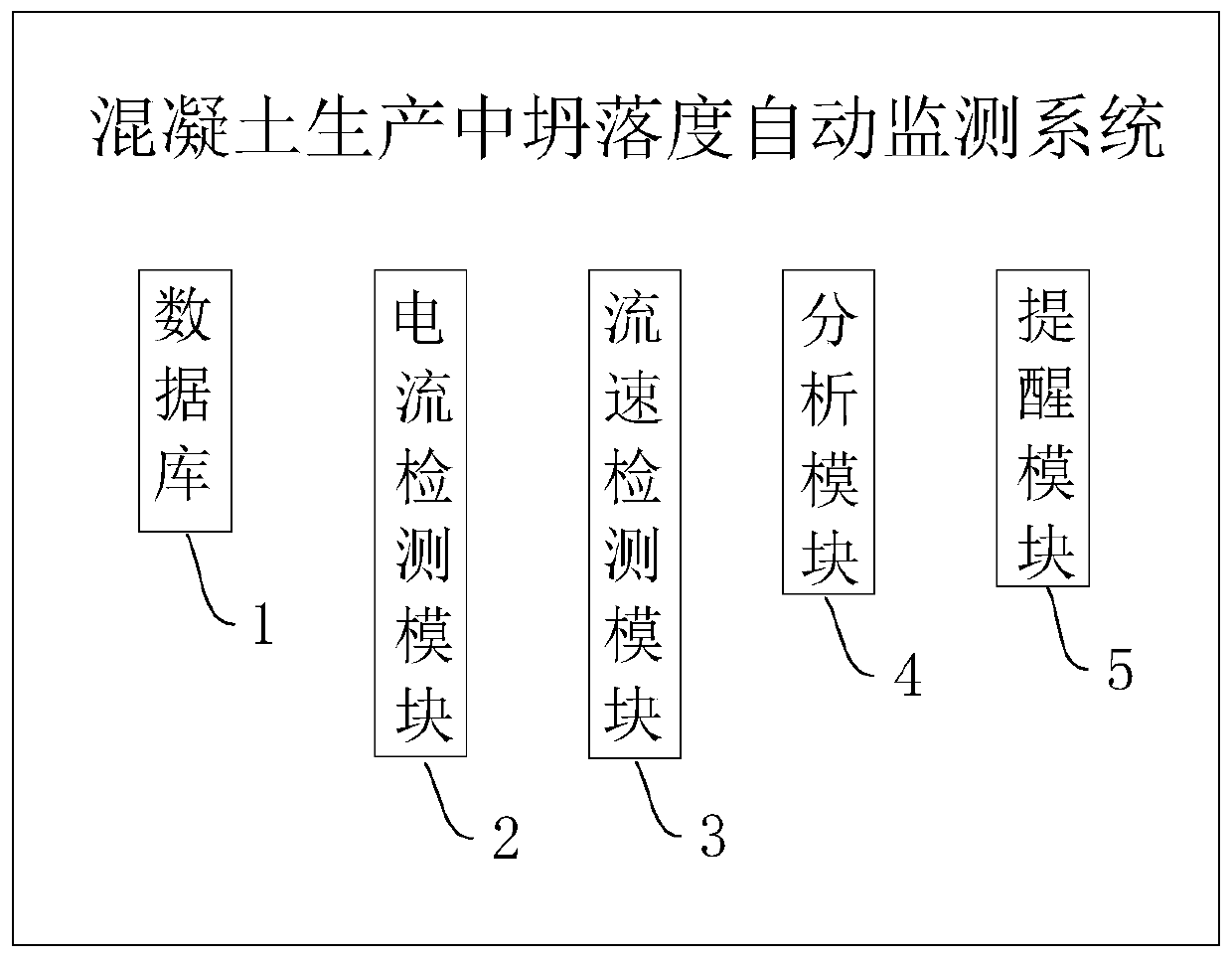

[0055] Embodiment 2: automatic slump monitoring system in concrete production, such as figure 2 As shown, for realizing the method in embodiment 1, it comprises database 1, electric current detection module 2, flow rate detection module 3, analysis module 4 and reminder module 5, wherein:

[0056] Database 1 stores the current value of the mixer corresponding to different specifications of concrete, the corresponding relationship between the flow rate value of the concrete discharge and the concrete slump, the production guidance of the corresponding degree of different slumped concrete, and the current value of the mixer at different heights The difference corresponds to the uniformity of the concrete table.

[0057] The corresponding relationship is obtained through experiments in advance, that is, the concrete slump corresponding to the different current values of the mixer and the concrete discharge flow rate values are obtained first, and the concrete corresponding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com