Electric vehicle charging socket mounting structure

A charging socket and installation structure technology, applied in electric vehicle charging technology, electric vehicles, charging stations, etc., can solve the problems of inconvenient charging operation, large space occupation, small space occupation, etc., to achieve good strength and rigidity, and space occupation. Small, easy to charge and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

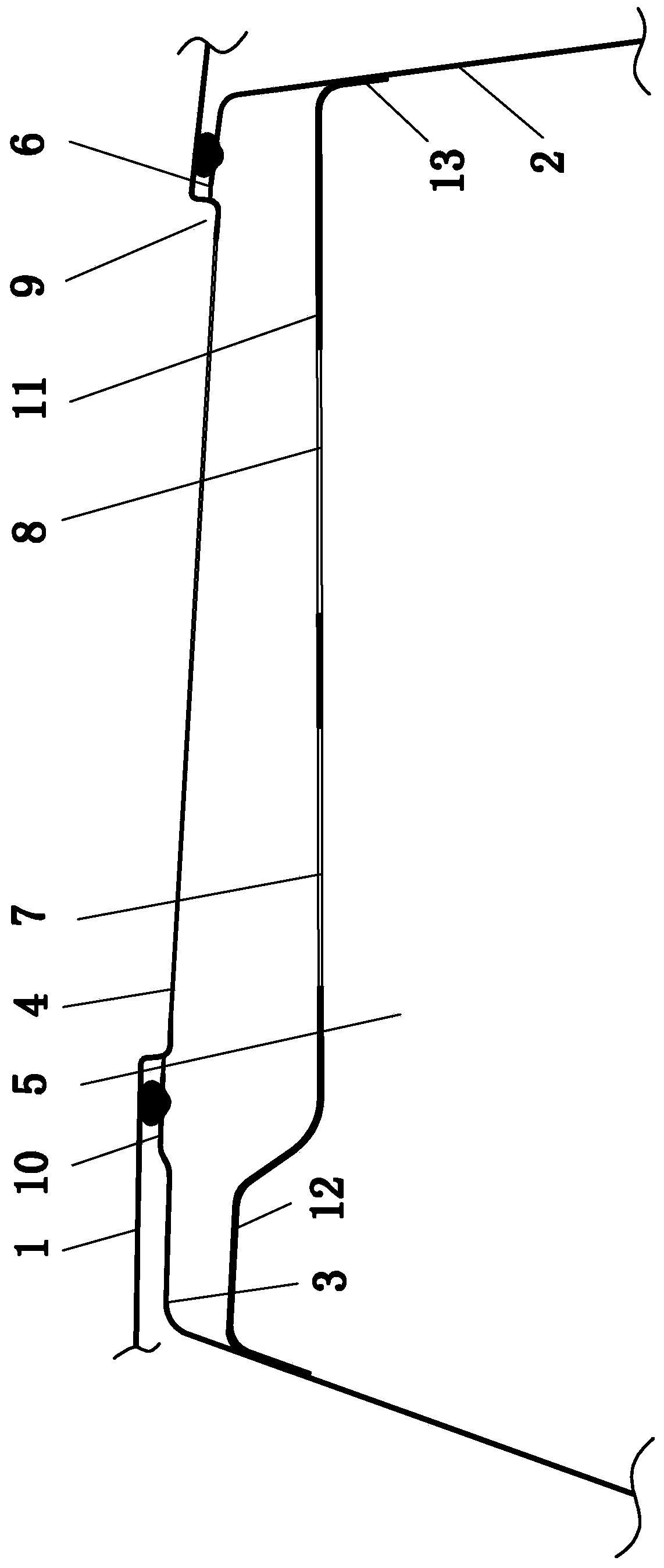

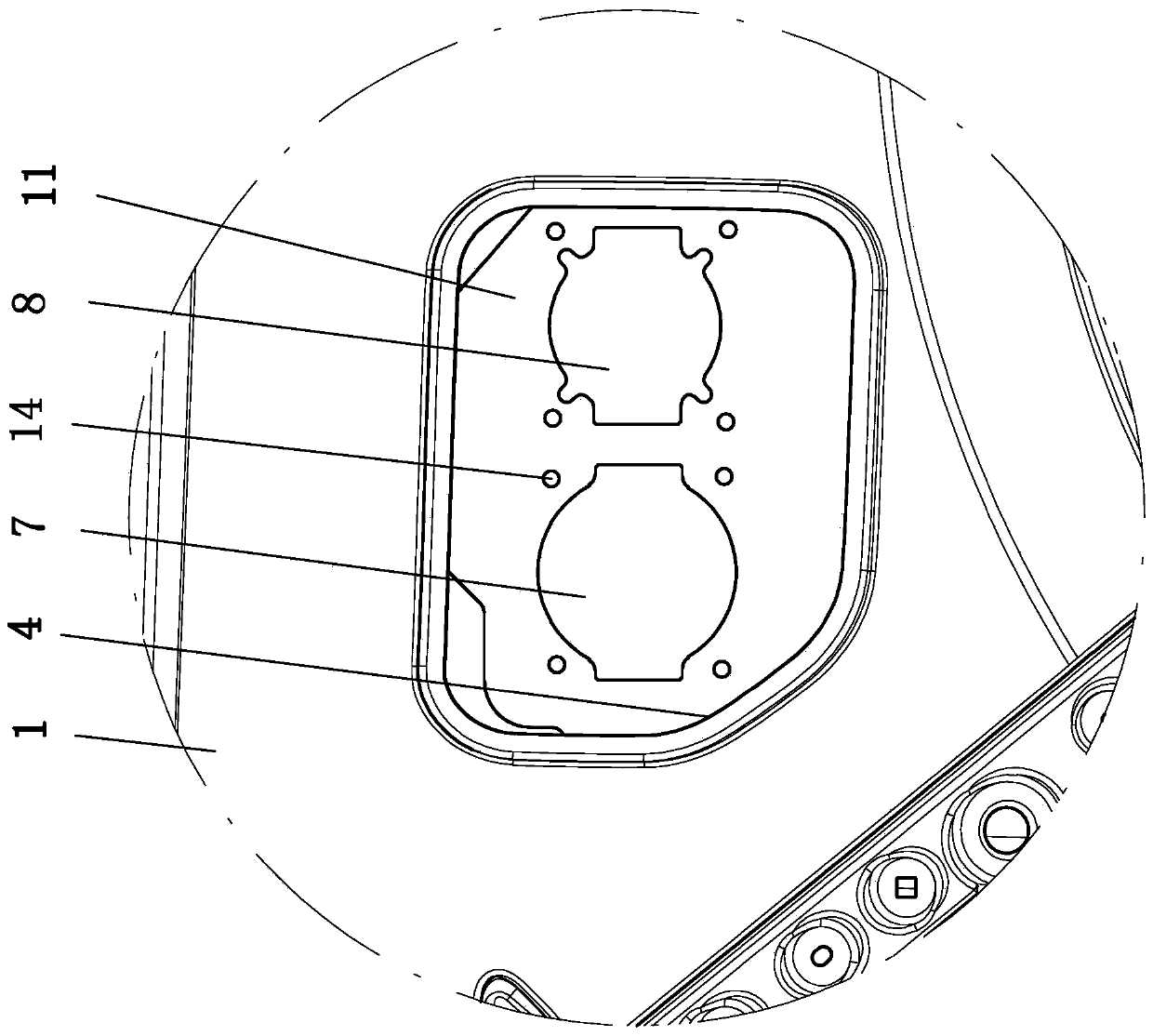

[0018] Example 1, such as figure 1 , figure 2 Shown: a charging socket installation structure for electric vehicles, including: a side wall outer plate 1, a wheel house outer plate 2, a boss 3 arranged at the outer end of the wheel house outer plate 2 and connected to the inner end of the side wall outer plate 1, The outer through hole 4 provided on the side wall outer panel 1, the counterbore 5 provided at the inner end of the boss 3, the inner through hole 6 provided at the bottom of the counterbore 5 and the outer end is opposite to the outer through hole 4, is provided with a quick charge Socket hole 7 and the charging socket bracket of slow charging socket hole 8; Charging socket bracket is connected with counterbore 5 inner sides and fast charging socket hole 7 and slow charging socket hole 8 are opposite to inner through hole 6 respectively.

[0019] The outer end of the side wall outer panel 1 is provided with a cover installation recess 9; the outer through hole 4 i...

Embodiment 2

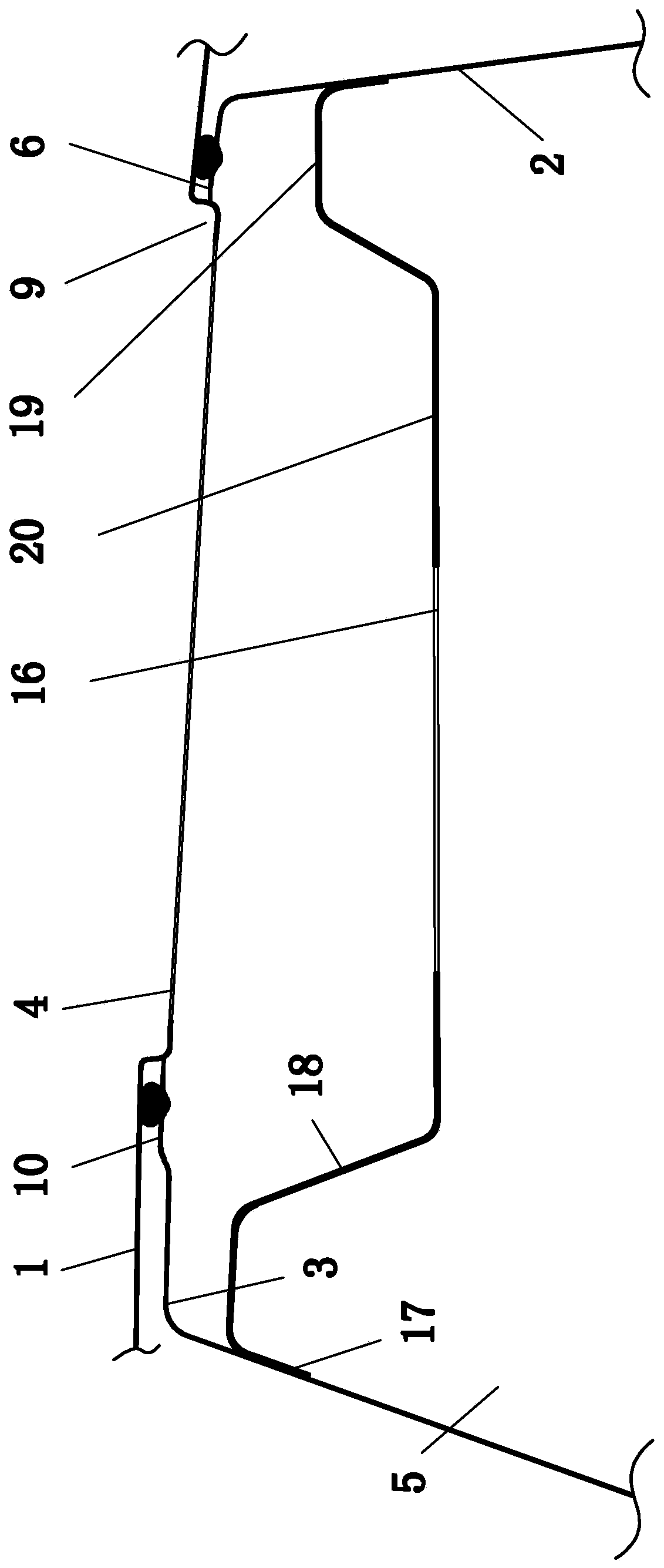

[0023] Example 2, such as image 3 , Figure 4 Shown: a charging socket installation structure for electric vehicles, including: a side wall outer plate 1, a wheel house outer plate 2, a boss 3 arranged at the outer end of the wheel house outer plate 2 and connected to the inner end of the side wall outer plate 1, The outer through hole 4 provided on the side wall outer panel 1, the counterbore 5 provided at the inner end of the boss 3, the inner through hole 6 provided at the bottom of the counterbore 5 and the outer end is opposite to the outer through hole 4, and an integrated socket is provided The integrated socket bracket of the hole 16;

[0024] The outer end of the side wall outer panel 1 is provided with a cover installation recess 9; the outer through hole 4 is located on the bottom surface of the cover installation recess 9.

[0025] In this example:

[0026] The outer end of the boss 3 is provided with a protruding ring 10 sleeved outside the inner through hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com