Straight pipe with adjustable suction force, adjustment method for suction force of straight pipe and vacuum cleaner

An adjustment method and suction technology, which is applied in the direction of vacuum cleaners, suction hoses, cleaning equipment, etc., can solve the problems of poor accuracy and single suction adjustment form, and achieve the effects of ensuring stability, reducing gas disturbance, and improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

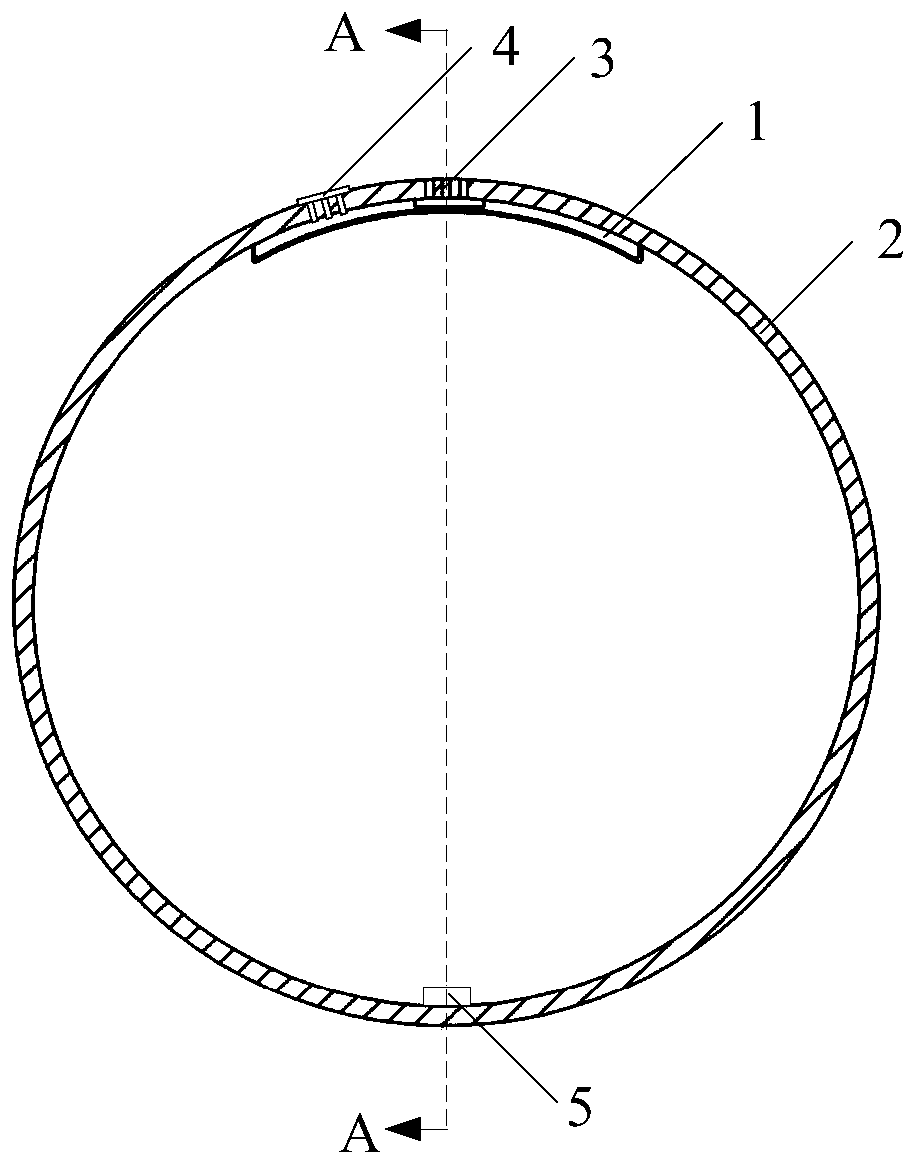

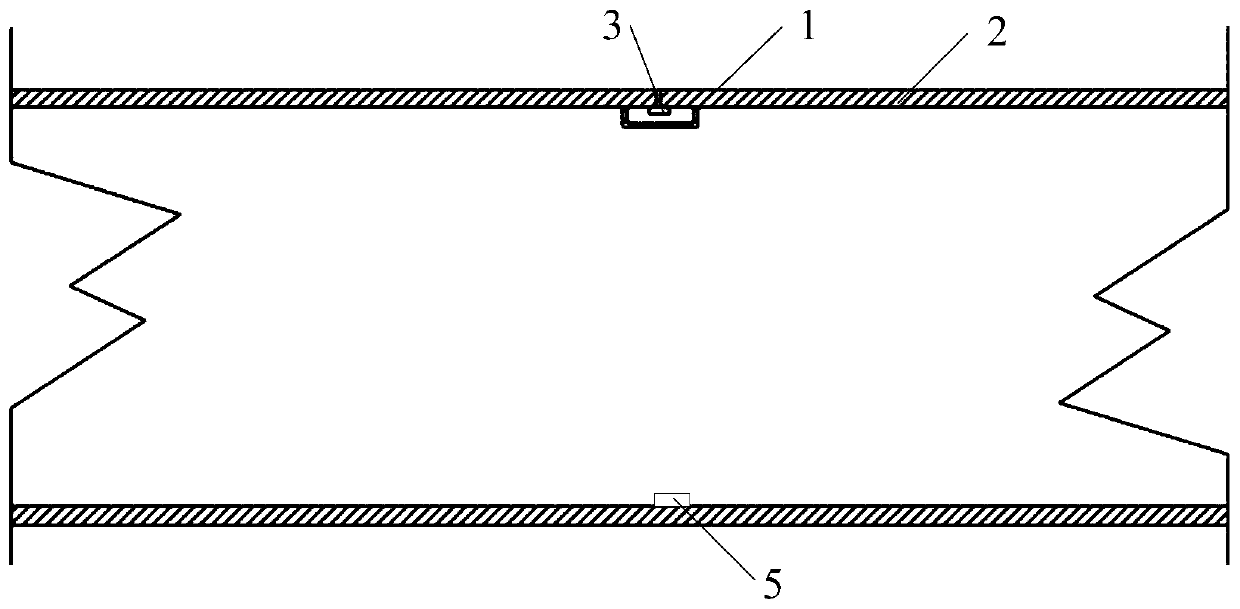

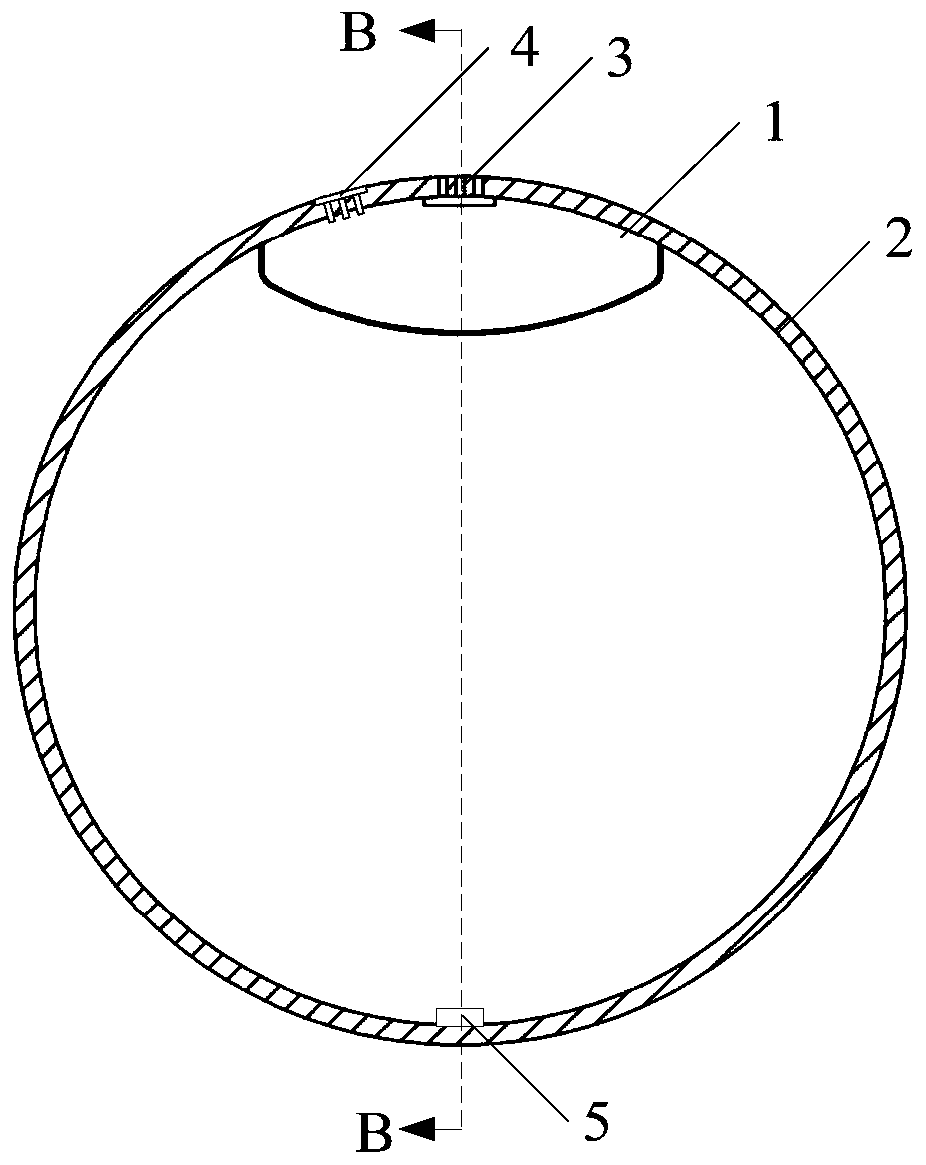

[0046] This embodiment provides a straight pipe with adjustable suction, see Figure 1 to Figure 6 , including a straight pipe body 2 and a suction adjustment assembly disposed on the inner wall of the straight pipe body 2, wherein the suction adjustment assembly includes a suction adjustment airbag 1 and an inflation and deflation assembly for inflating and deflation of the suction adjustment airbag 1. It should be noted that the suction regulating airbag 1 is an elastic airbag, and the volume of the suction regulating airbag 1 can be adjusted by adjusting the gas volume filled into the suction regulating airbag 1 .

[0047] When it is necessary to increase the suction in the straight pipe, open the inflation and deflation assembly to inflate the suction adjustment airbag 1, so that the volume of the suction adjustment airbag 1 increases, the radial cross-sectional area of the straight pipe becomes smaller, and the flow rate remains basically unchanged. , the gas flow rate ...

Embodiment 2

[0059] The structure of the straight pipe with adjustable suction provided by this embodiment is basically the same as the structure of the straight pipe with adjustable suction provided by Embodiment 1, the only difference is that the air pressure sensor 6 is used instead of the suction gauge 55, see Figure 7 to Figure 8 , by measuring the gas pressure in the suction-adjusting airbag 1 and indirectly reflecting the volume of the suction-adjusting airbag 1, therefore, the above-mentioned straight pipe with adjustable suction can also include a processor 7, a suction-adjusting key 8 and a function for detecting the suction-adjusting airbag 1. The air pressure sensor 6 of the gas pressure, the processor 7 and the suction adjustment key 8 are all arranged in the main body of the vacuum cleaner, and the processor 7 can communicate with the suction adjustment key 8, The air pressure sensor 6, the air supply unit, the suction valve and the air discharge valve 4 are connected. When ...

Embodiment 3

[0063] This embodiment provides a method for adjusting the suction of a straight pipe. The straight pipe with adjustable suction provided in Embodiment 1 is used. When increasing the suction, the above-mentioned straight pipe suction adjustment method includes the following steps:

[0064] Step 1: Adjust the suction adjustment key, and the processor obtains the set suction value corresponding to the corresponding gear of the suction adjustment key;

[0065] Step 2: The processor controls the opening of the inflation and deflation component, and the inflation and deflation component fills the suction adjustment airbag with gas;

[0066] Step 3: The processor obtains the real-time suction value in the straight pipe body collected by the suction gauge in real time;

[0067] Step 4: The processor compares the real-time suction value with the set suction value in real time. When the real-time suction value is greater than or equal to the set suction value for the first time, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com