Three time-coated motorcycle catalyst and a preparation method thereof

A motorcycle and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as the inability to meet the HC catalytic capacity, and achieve the effect of improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

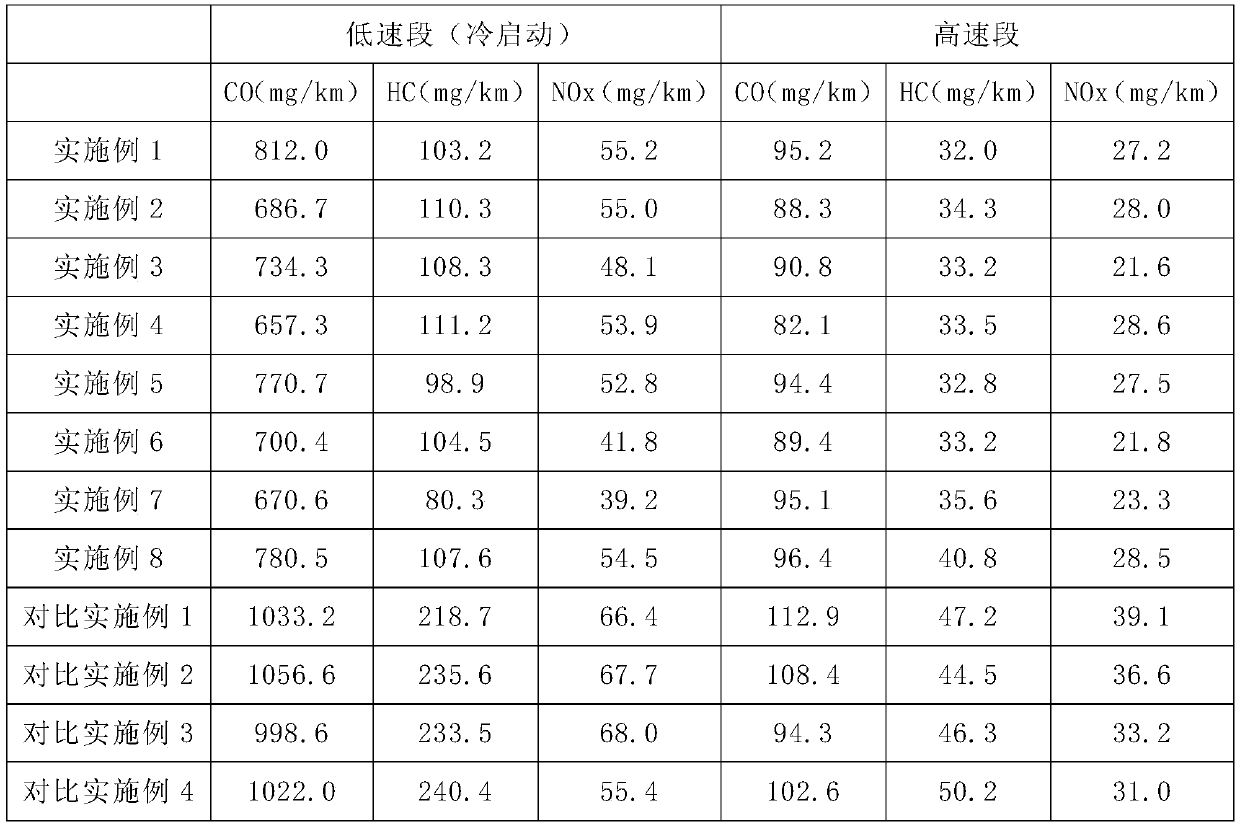

Examples

Embodiment 1

[0027] A triple-coated motorcycle catalyst, including a honeycomb metal carrier, the size of the honeycomb metal carrier is φ48.6*130*120, the pore density is: 300CPSI, and the volume is 0.205L; at the inlet end of the metal carrier The first precious metal coating is coated on the top, the coating amount of the first noble metal coating is 100g / L, and the usage amount of Pd is 50g / ft 3 ; Coating the second precious metal coating on the gas outlet end of the metal carrier, the coating amount of the second noble metal coating is 100g / L, and the usage amount of Pd is 20g / ft 3 , the coating height of the first noble metal coating and the second noble metal coating is 1:1; the third noble metal coating is coated on the second noble metal coating, and the coating amount of the third noble metal coating is 40g / L, The amount of Rh used is 5g / ft 3 .

[0028] The preparation method of the three-time coating catalyst of the motorcycle adopts the following process steps:

[0029] (1) ...

Embodiment 2

[0033]A triple-coated motorcycle catalyst, including a honeycomb metal carrier, the size of the honeycomb metal carrier is φ48.6*130*120, the pore density is: 300CPSI, and the volume is 0.205L; on the inlet end of the metal carrier Apply the first noble metal coating, the coating amount of the first noble metal coating is 100g / L, and the usage amount of Pt is 10g / ft 3 , the amount of Pd used is 40g / ft 3 ; Coating the second precious metal coating on the gas outlet end of the metal carrier, the coating amount of the second noble metal coating is 100g / L, and the usage amount of Pd is 20g / ft 3 , the coating height of the first noble metal coating and the second noble metal coating is 1:1; the third noble metal coating is coated on the second noble metal coating, and the coating amount of the third noble metal coating is 40g / L, The amount of Rh used is 5g / ft 3 .

[0034] The preparation method of the three-time coating catalyst of the motorcycle adopts the following process ste...

Embodiment 3

[0039] A three-time coated motorcycle catalyst, including a honeycomb metal carrier, the size of the honeycomb metal carrier is φ48.6*130*120, the pore density is: 300CPSI, and the volume is 0.205L; it is coated on the inlet end of the metal carrier The first noble metal coating, the coating amount of the first noble metal coating is 100g / L, and the usage amount of Pt is 5g / ft 3 , the amount of Pd used is 40g / ft 3 , the dosage of Rh is 5g / ft 3 ; Coating the second noble metal coating on the gas outlet of the metal carrier, the coating amount of the second noble metal coating is 100g / L, and the usage amount of Pd is 20g / ft 3 , the coating height of the first noble metal coating and the second noble metal coating is 1:1; the third noble metal coating is coated on the second noble metal coating, and the coating amount of the third noble metal coating is 40g / L, The amount of Rh used is 5g / ft 3 .

[0040] The preparation method of the three-time coating catalyst of the motorcyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap