Vacuum hole bracket for LED wafer automatic sorting machine

An automatic sorting and vacuum bracket technology, applied in sorting and other directions, can solve the problems of reduced processing efficiency, complex structure, LED chip damage, etc., and achieve the effect of ensuring flatness and uniform adsorption force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

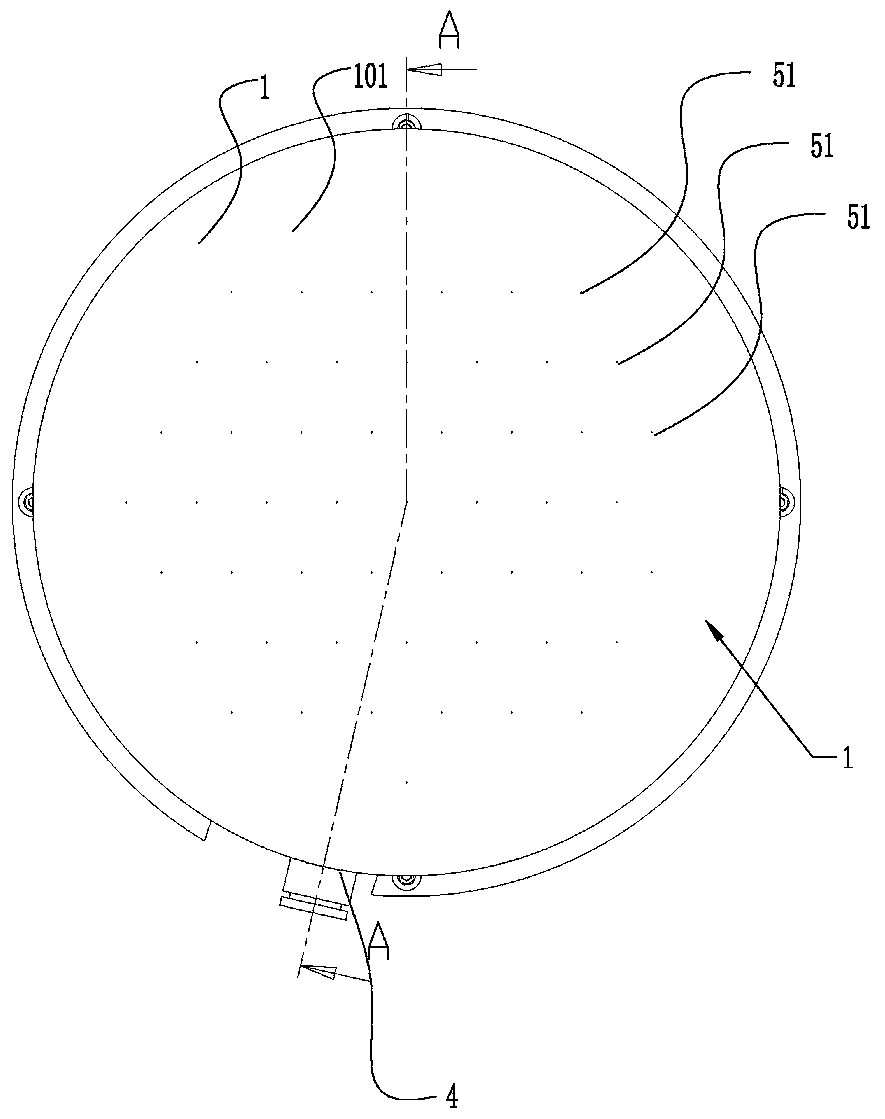

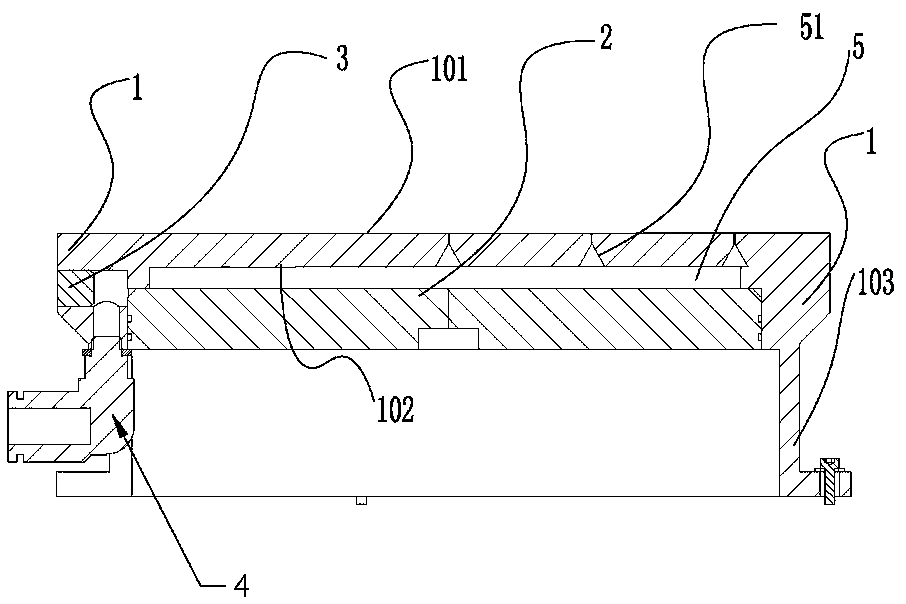

[0018] Examples, as attached figure 1 And attached figure 2 As shown, a vacuum hole bracket for an automatic LED wafer sorting machine includes a vacuum bracket body 1, a vacuum hole bracket sealing cover 2 is connected to the bottom of the vacuum bracket body 1, and the vacuum bracket body 1 and the vacuum hole bracket There is a gap between the frame sealing covers 2 to form a negative pressure chamber 5; the vacuum hole bracket sealing cover 2 and the vacuum hole bracket 1 are assembled with sealant.

[0019] Several vacuum hole bracket process holes 3 are arranged on the outer circumference of the vacuum hole bracket 1 .

[0020] The vacuum hole bracket 1 has an upper surface 101 and a lower surface 102. The upper surface 101 is a plane, and the lower surface 102 is a plane. The lower surface 102 of the vacuum hole bracket 1 is distributed with several microholes 51, and the several microholes 51 are generally in the shape of Arranged in a hexagonal shape, the arrangeme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com