Super-thick plate splicing method

A seam and deck technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of uneconomical, time-consuming, high cost, etc., and achieve the effect of reducing economic costs and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

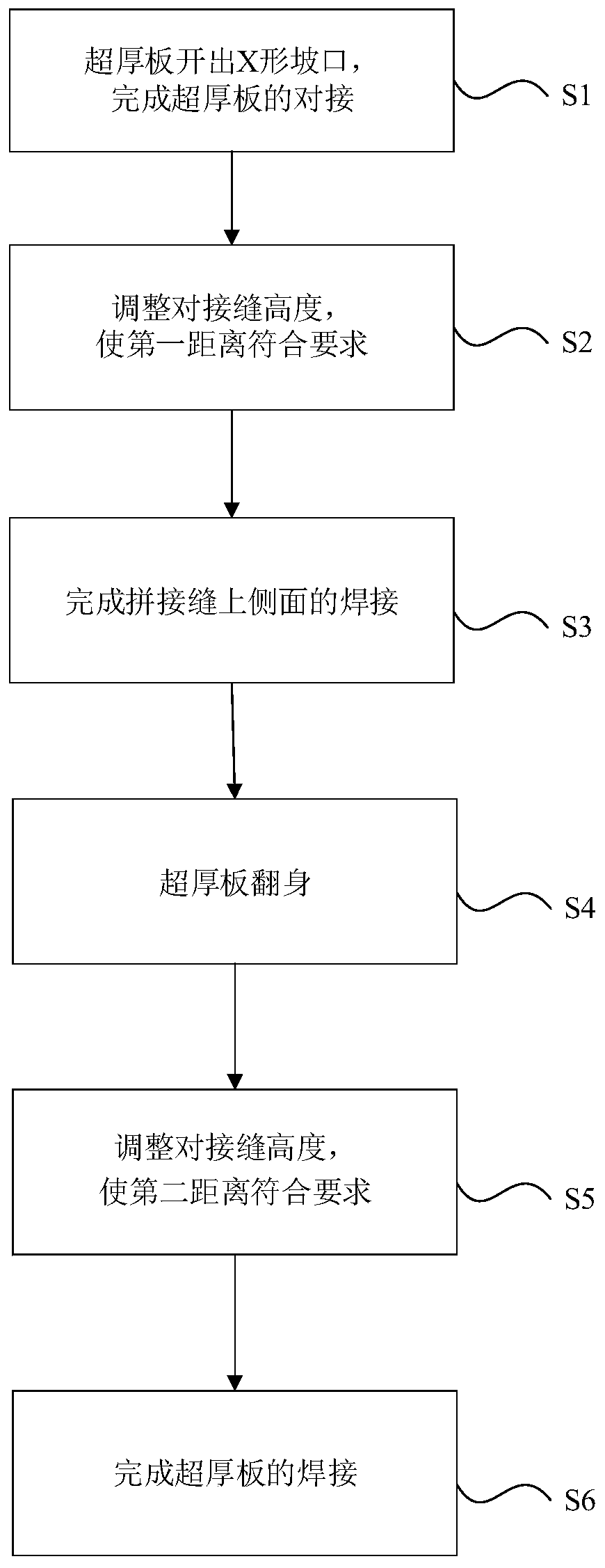

[0088] Such as figure 1 As shown, this embodiment discloses a method for splicing super-thick plates. This method is used for the welding of crack arresting steel on ships, and the method for super-thick plate splicing includes the following steps:

[0089] Step S1: An X-shaped bevel is made at one end of the super-thick board for splicing, and after completion, the super-thick board is placed on a flat tire frame to complete the butt joint of the super-thick board. Different super-thick boards The butt joints of the thick plates form a seam, the upper side of the ultra-thick plate is the first surface, and the lower side of the ultra-thick plate is the second surface;

[0090] Step S2: raising the seam, the second surface of the super-thick plate on both sides of the seam extends to the plane where the seam is located to form an intersection line, and the intersection line and The distance between the tire frames is a first distance, and the size of the first distance is ad...

Embodiment 2

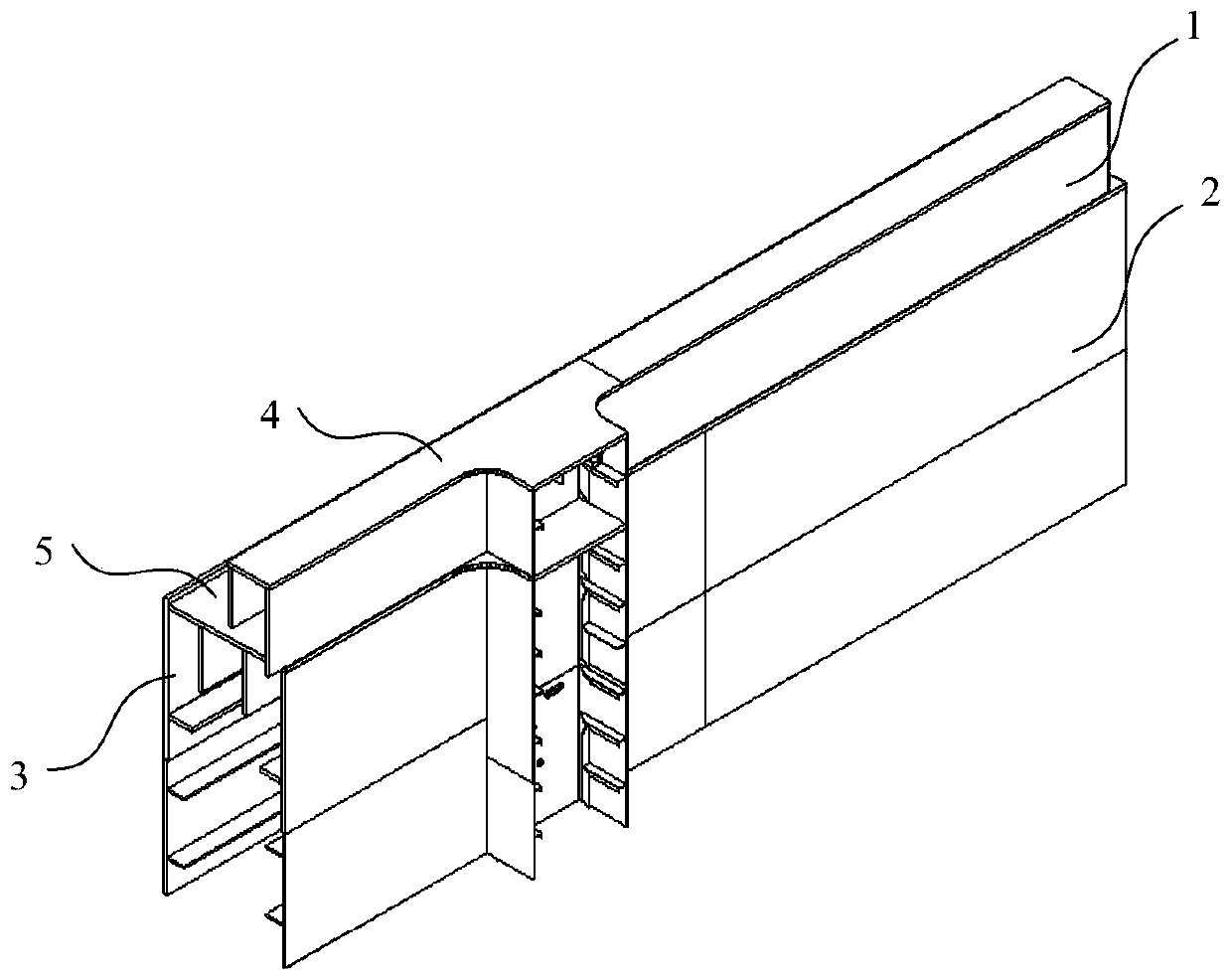

[0098] Such as Figure 2-9 As shown, this embodiment discloses the specific implementation of applying the present invention to the welding of super-thick plates of ships.

[0099] figure 2 It is a schematic diagram of the structure of the torsion box area of a container ship. The thickness of the ultra-thick plate included in the torsion box is 45mm-85mm, and the material of the ultra-thick plate is crack stop steel. Longitudinal bulkhead of torsion box 2, shell plate of torsion box 3, hatch coaming top plate 4 and upper deck of torsion box 5. The thickness range of the hatch coaming 1, the longitudinal bulkhead 2 of the torsion box, the shell plate of the torsion box 3 and the hatch coaming top plate 4 is 50mm-85mm, and the thickness of the upper deck 5 of the torsion box is 45mm-85mm.

[0100] Such as Figure 3-5 As shown, it is a schematic diagram of super-thick plate transverse splicing. The method of the present invention will be described in detail below.

[010...

Embodiment 3

[0115] Such as Figure 10 As shown, this embodiment discloses the specific implementation of applying the present invention to the welding of super-thick plates of ships.

[0116] This embodiment 3 is basically the same as embodiment 2, the difference is:

[0117] Embodiment 3 is the splicing of the longitudinal splicing seam T of the ultra-thick plate. When welding the longitudinal seam T, since the length of the longitudinal seam T is relatively long, it is necessary to arrange a plurality of jacks 9 below the seam T to ensure the smoothness of the seam T. The first distance C1 and the second distance C2 of the first steel plate 101 and the second steel plate 102 are different from the first distance C1 and the second distance C2 of the transverse splicing seam S of the super-thick plate. Specifically, when splicing the longitudinal seam T, the first distance C and the second distance C2 between the longitudinal bulkhead 2 of the torsion box and the shell plate 3 of the to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com