Intelligent perforating machine used for manufacturing circuit board

A technology of sheet material production and punching machine, which is applied in the fields of printed circuit manufacturing, printed circuit, metal processing, etc., can solve the problem of lack of sheet material fixing mechanism, etc., and achieve the effect of improving drilling accuracy and preventing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

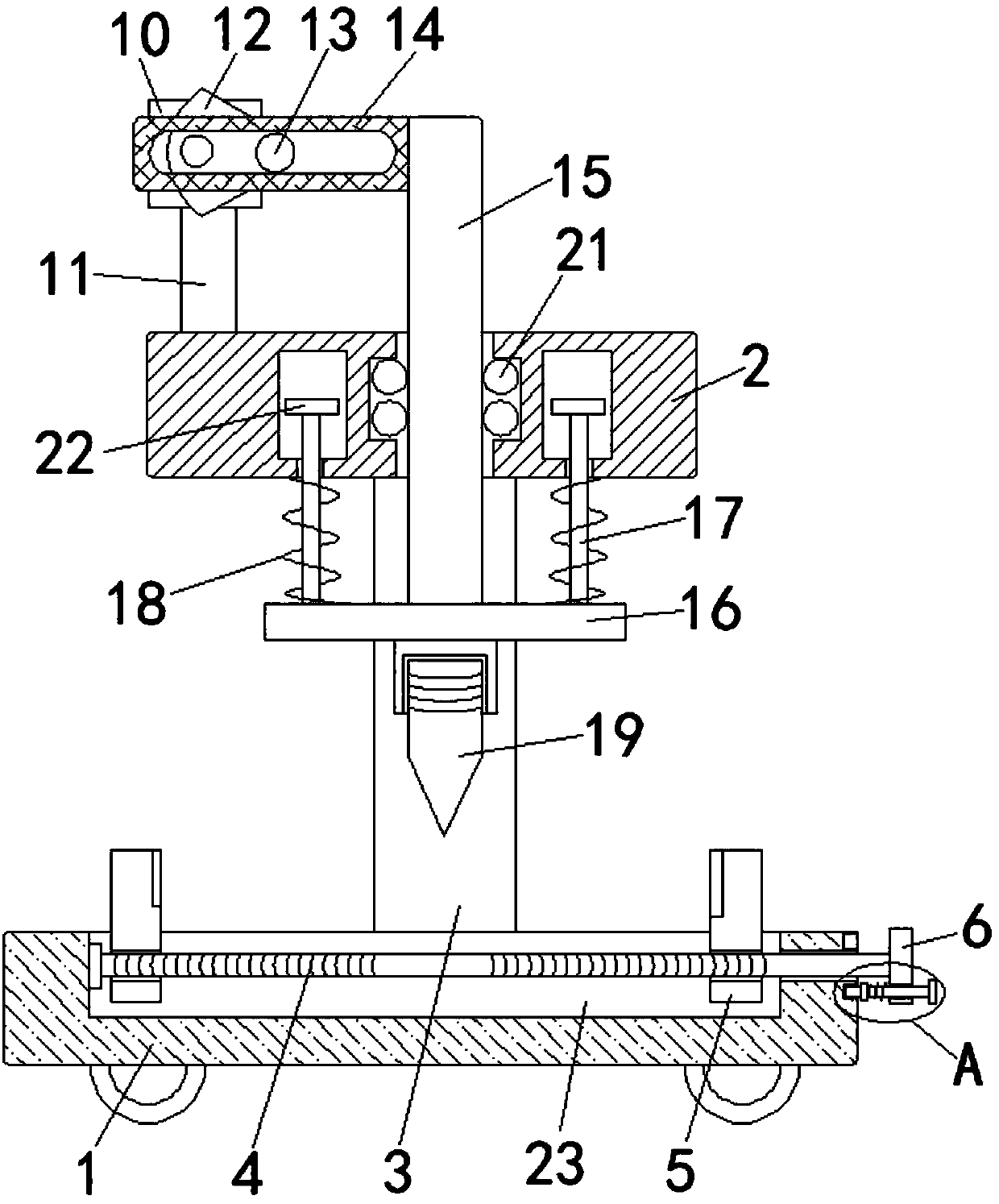

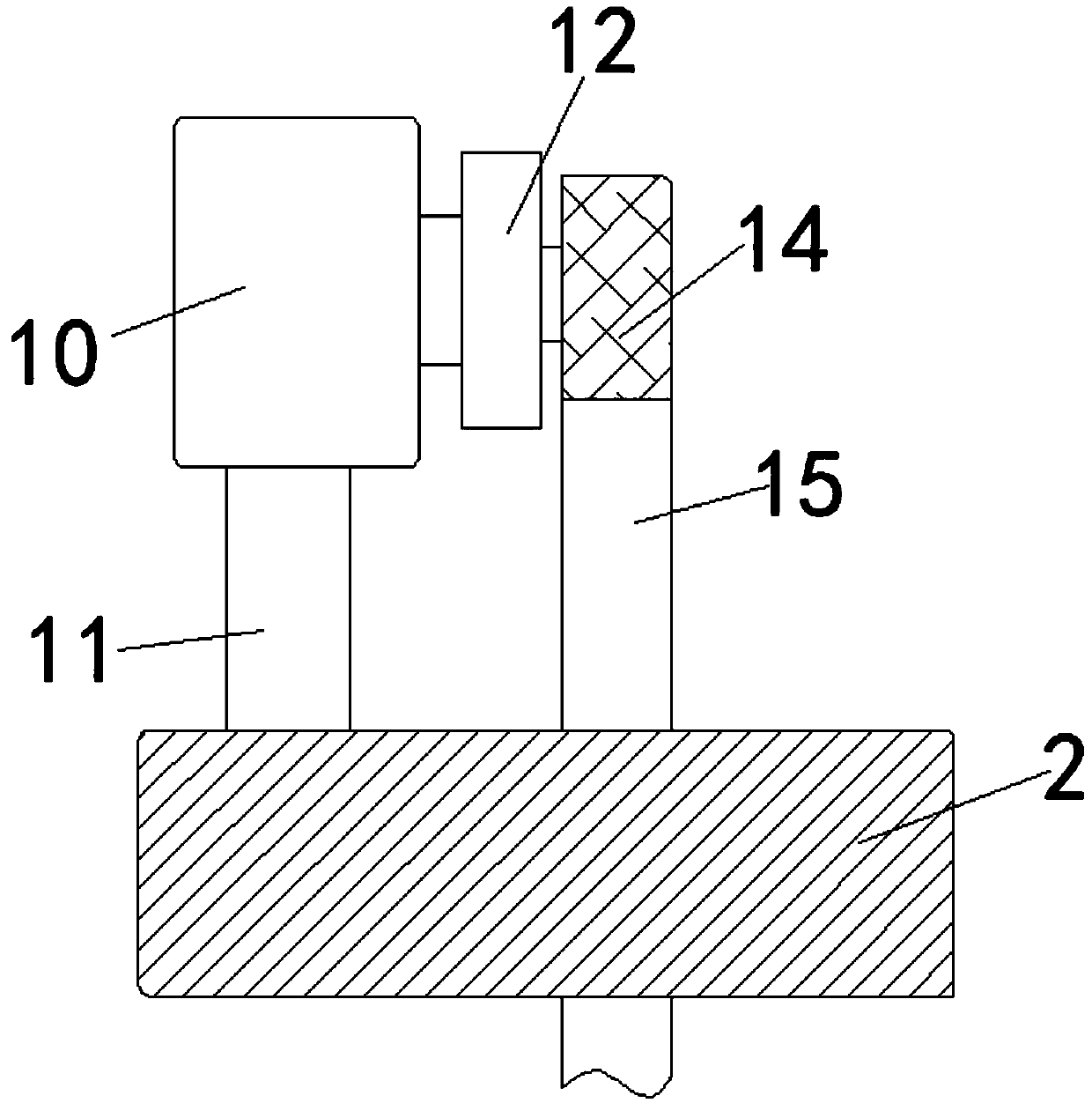

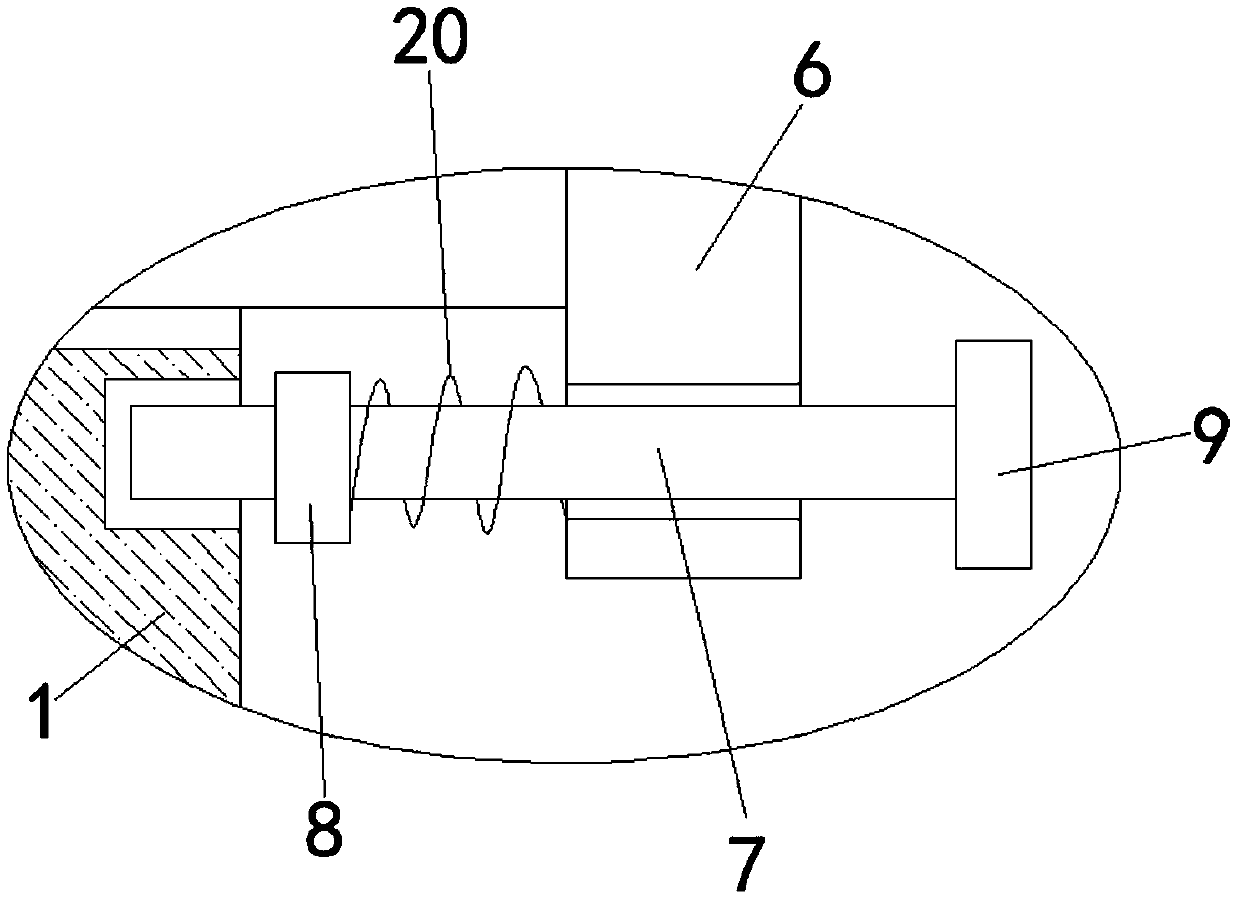

[0027] refer to Figure 1-3 , an intelligent punching machine for making circuit boards, comprising a base 1 and a support plate 2 arranged in parallel, the base 1 and the support plate 2 are fixedly connected by a column 3, and the top of the base 1 is provided with a mounting groove 23 for use For placing the plate, a screw 4 is rotatably connected in the installation groove 23 to drive the fixed plate 5 to move. Two opposite fixed plates 5 are threaded on the screw 4 to fix the plate. One end of the screw 4 runs through the installation groove The inner wall of 23 is fixedly connected with a handle 6 for rotating the screw rod 4. One end of the handle 6 is slidably inserted with a clamping rod 7 for fixing the handle 6. The outer wall of the base 1 is surrounded by a plurality of corresponding clamping rods 7. Draw-in slot, one end of the clamping rod 7 close to the base 1 is fixedly sleeved with a ferrule 8 to prevent the clamping rod 7 from falling off from the handle 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com