Processing device of carbon fiber composite material blade grid and blade grid

A processing device and composite material technology, applied in household components, household appliances, other household appliances, etc., can solve problems such as inability to demold, difficult demoulding, etc., to achieve high processing efficiency, ensure structural integrity, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

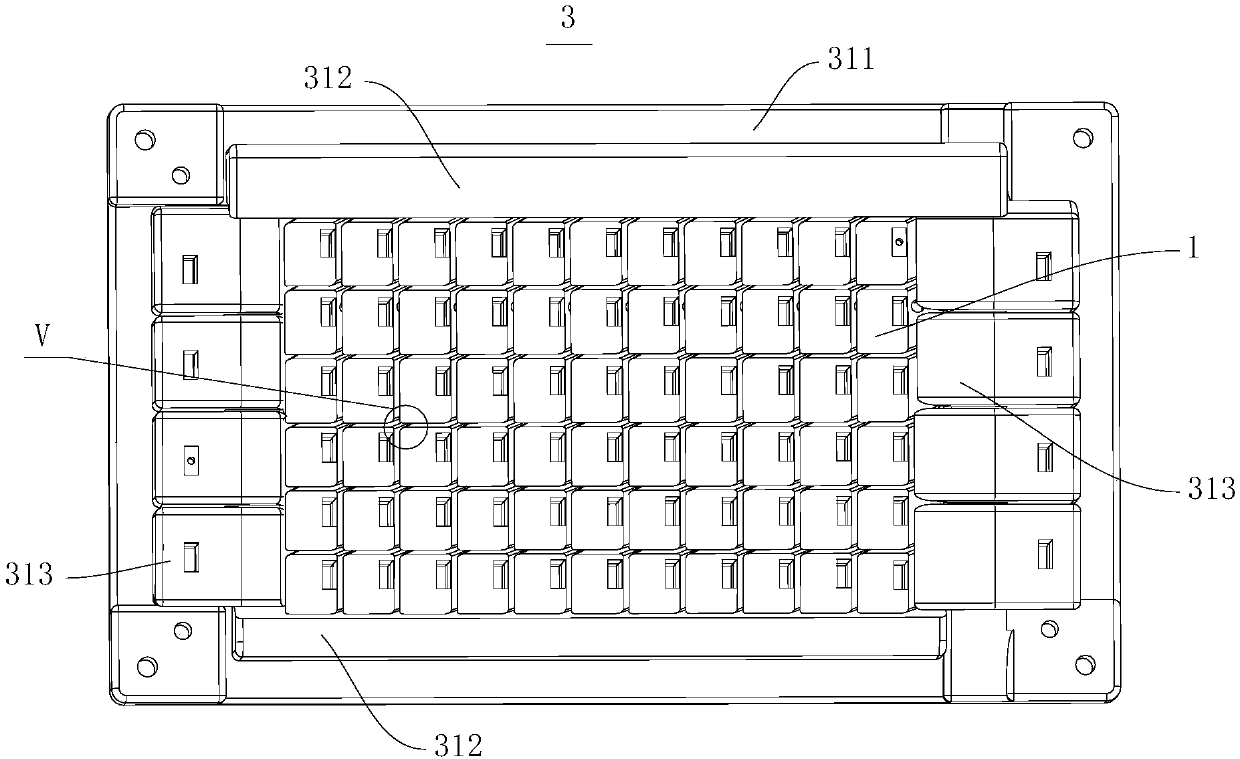

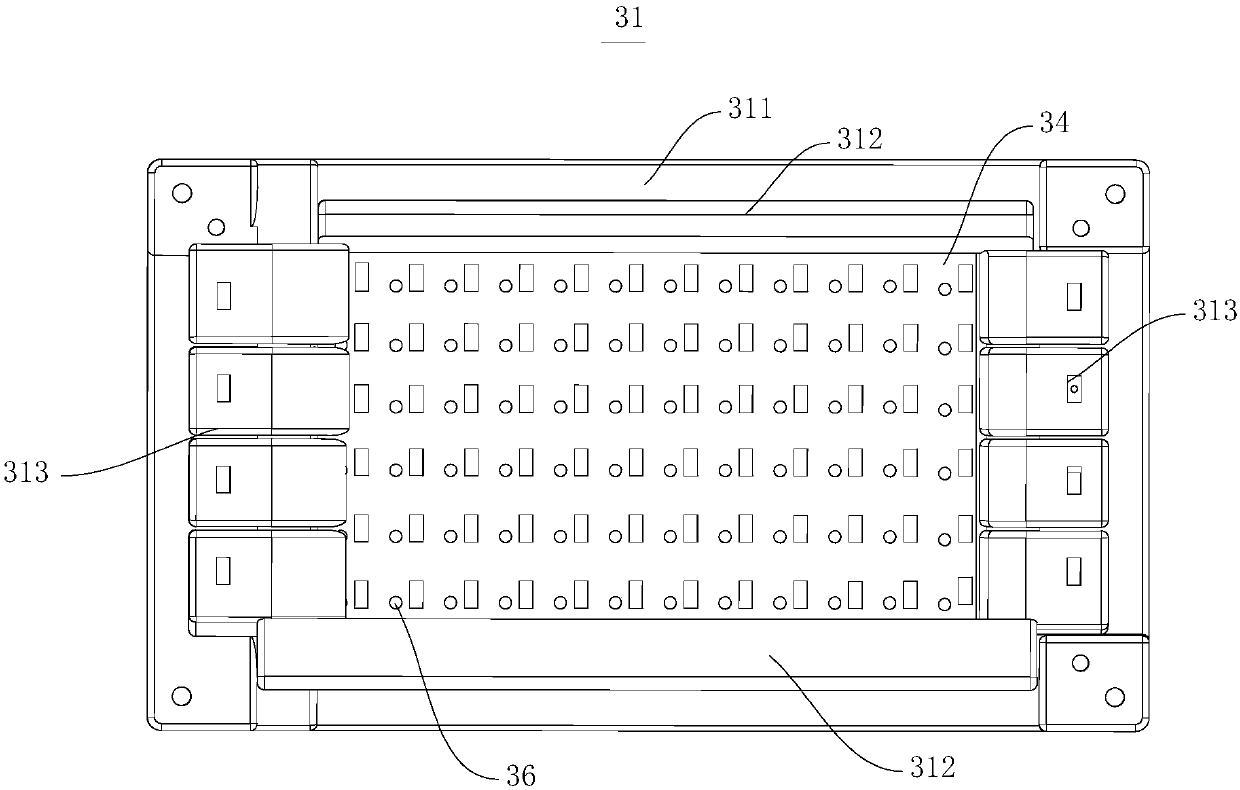

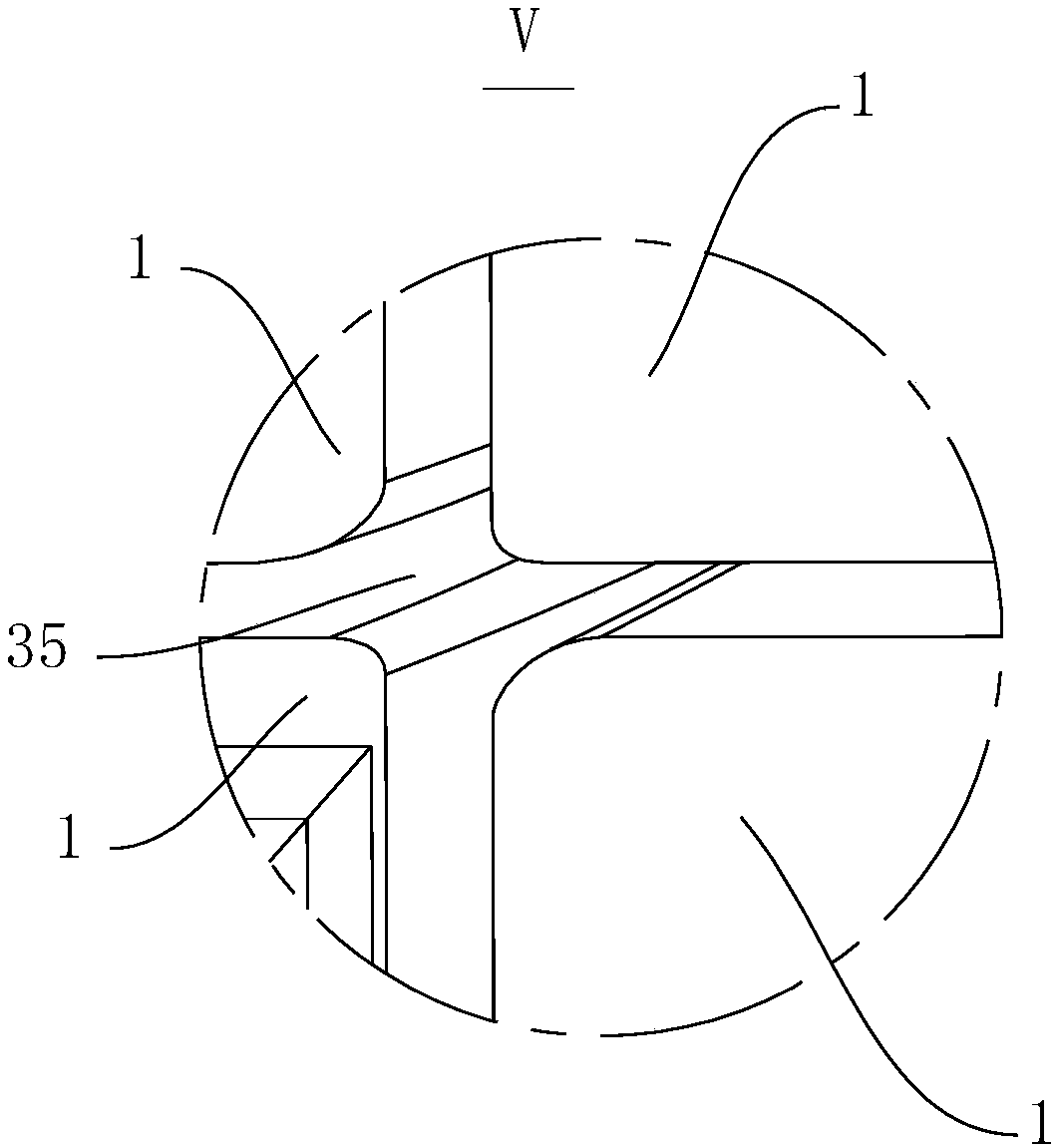

[0045] see Figure 1-Figure 11 , the present invention provides a processing device 3 for a composite cascade 2 . This processing device 3 includes a base 31 and a plurality of processing mandrels 1, the base 31 is detachably connected with the processing mandrels 1; the processing mandrel 1 includes a molding assembly, and the molding assembly has a molding surface adapted to the shape of the hole 21 18. The molding surface 18 is used for contacting with carbon fiber composite materials; the molding assembly includes a first assembly block 11, a second assembly block 12 and a demoulding insert 13, and the demoulding insert 13 can be arranged on the first assembly block 11 and the second assembly block 11. between the combination blocks 12 and spliced with the first combination block 11 and the second combination block 12 to form a molding surface 18 .

[0046] The surface at one end of the cascade 2 in the thickness direction is the first surface 22 , and the surface at th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap