Embedded type multistage elevator buffer and working method thereof

A buffer, embedded technology, used in elevators, transportation and packaging, etc., can solve the problem that the height of the pit cannot be changed, and achieve the effects of compact structure, high construction cost and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

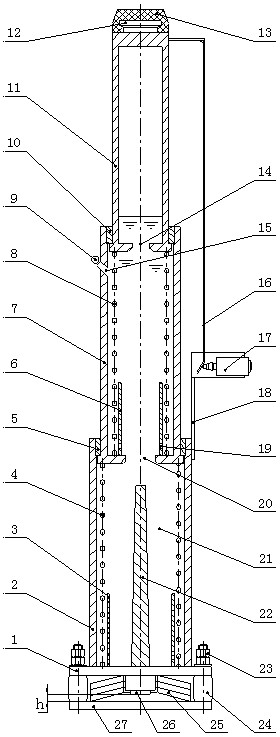

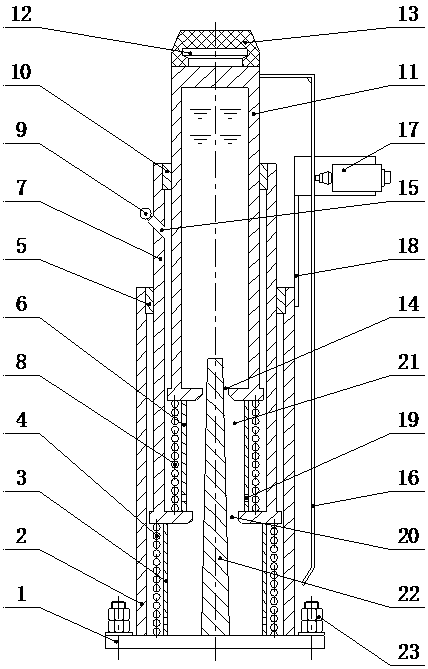

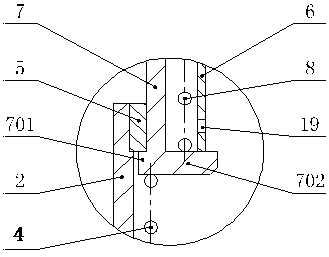

[0030] The embedded multi-stage elevator buffer of the present invention includes a hydraulic cylinder bottom plate 1 and a hydraulic cylinder 2 arranged on the hydraulic cylinder bottom plate 1. The hydraulic cylinder 2 is sealed with a second-stage plunger 7 that can lift and slide along the hydraulic cylinder body. And the second-stage return spring 4 positioned below the second-stage plunger 7, said second-stage plunger 7 is sealed in the body and is provided with a first-stage plunger that can lift and slide along the second-stage plunger body and is located at the first stage. The first-stage return spring 8 below the plunger 11, the inner chambers of the hydraulic cylinder 2, the second-stage plunger 7 and the first-stage plunger 11 communicate with each other, and the hydraulic cylinder, the second-stage plunger and the first stage Hydraulic oil 21 is filled in the cavity of the plunger.

[0031] In order to limit the further decline of the plunger, a second-stage stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com