Regulation and control method for obtaining dispersed nano precipitated phase in FeCrAl alloy

A technology of nano-precipitated phases and alloys, which is applied in the control field of obtaining dispersed nano-precipitated phases to achieve excellent high-temperature structural stability, optimized and reliable technical solutions, and fixed process parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

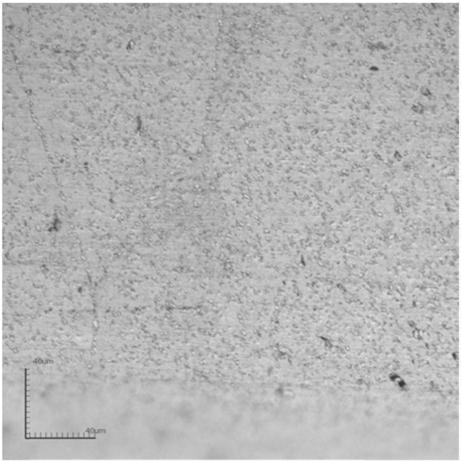

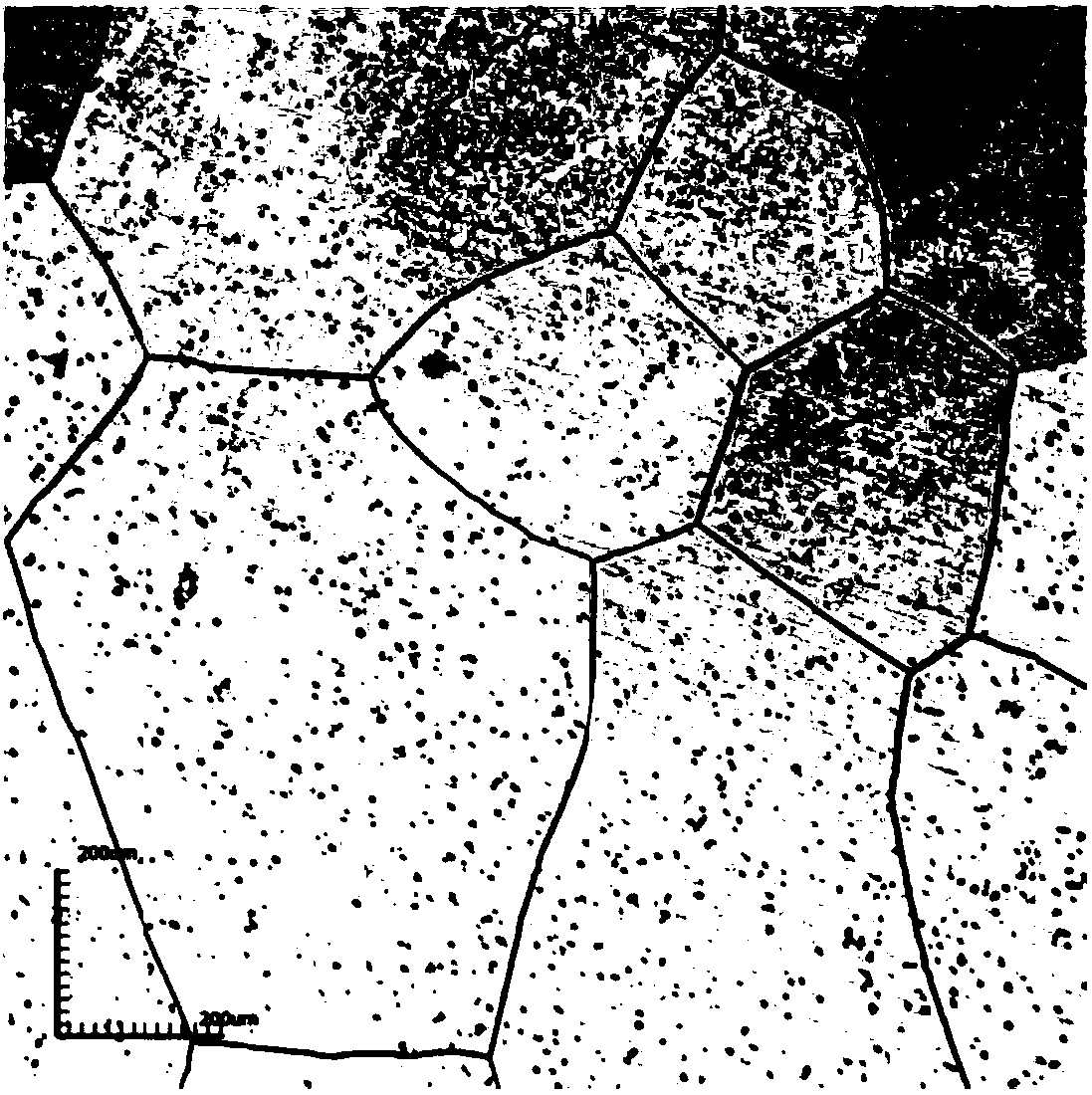

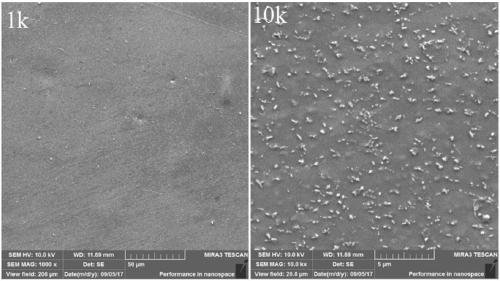

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0021] According to the following technical scheme, the second phase in the FeCrAl alloy can be effectively regulated, and a new type of accident-resistant FeCrAl alloy material with a dispersed distribution of high-density nano-precipitated phases can be prepared.

[0022] FeCrAl alloy material, the material is characterized in that the main alloying elements are Cr, Al, Nb, Mo, etc. By weight percentage, Cr: 12.5-14.5%, Al: 3.5-5.5, Mo: 1.5-3%, Nb: 0.5-3%, C: not higher than 0.008%, N: not higher than 0.005%, O: not higher than 0.003%, and the balance is iron and other trace elements.

[0023] A control method for obtaining dispersed nano-precipitated phases in a FeCrAl alloy of the present invention, specifically comprising the following steps:

[0024] Step 1, solid solution of FeCrAl alloy material, get FeCrAl alloy material, carry out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com