Method and device for purifying concentrated corn steep liquor through brush filter in monosodium glutamate production

A technology of filter and corn steep liquor, which is applied in application, food heat treatment, food preparation, etc. It can solve the problems of extraction process influence, denaturation flocculation, and blocked pipelines, so as to improve pipeline transportation efficiency and equipment utilization, reduce dirt formation, The effect of saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

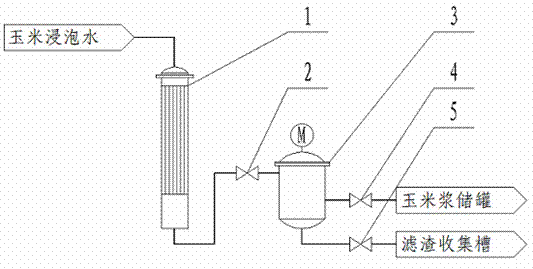

[0043] Example 2 In the production of monosodium glutamate, the method and device of using a brush filter to purify concentrated corn steep liquor, the operation steps and structure can still refer to the attached figure 1 , but different from Example 1, wherein the liquid handling capacity of the brush filter 3 is 800m 3 / h, the heat exchange area of evaporator 1 is 150m 2 .

[0044] Currently 500m 3 During the fermentation process, about 20 tons of concentrated corn steep liquor should be used, and after high-temperature sterilization at about 150°C at 0.13-0.16 MPa, the amount of sediment produced is about 5 tons. After utilizing the method and device of the present invention to purify concentrated corn steep liquor, the amount of precipitation is reduced to 0.5 tons. Most of the filter residue obtained after being filtered by a brush filter is protein, which can be added to corn bran to make feed to increase benefits. After accounting for 1,000 tons of corn steep liquor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com