Stable gamma' phase intensified Co-Ni-V-Al-base high temperature alloy

A co-ni-v-al, superalloy technology, applied in the field of Co-Ni-V-Al-based superalloys, can solve the problems of poor high temperature microstructure stability, increase alloy density, unfavorable applications in the aviation field, etc., and achieve excellent high temperature Tissue stability, effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Weigh high-purity Co, Ni, V and Al elemental materials according to the composition ratio shown in alloys 1, 2, 3, and 4 in Table 1; put the above-mentioned high-purity elemental materials weighed into an electric arc melting furnace, and In the atmosphere, the current is gradually increased to 50-300A, so that the raw materials are melted evenly, and melted into a Co-based superalloy ingot; in a high-purity argon atmosphere, the above-mentioned cast material is placed in a solid solution treatment at 1200 ° C for 12 hours, and quenched in ice water; Then aging treatment at 900° C. for 48 hours, and quenching in ice water to obtain a Co-Ni-V-Al-based superalloy strengthened by the steady-state γ′ phase.

Embodiment 2

[0042] Weigh high-purity elemental materials such as Co, Ni, V, and Al according to the composition ratio shown in alloy 6 and 20 in Table 1; put the above-mentioned high-purity elemental materials weighed into an electric arc melting furnace, and gradually Increase the current to 50-300A, so that the raw materials are smelted evenly, and smelted into a Co-based superalloy ingot; in a high-purity argon atmosphere, put the above-mentioned cast material at 1200°C for solution treatment for 12 hours, and quench it in ice water; Aging treatment at ℃ for 45 hours, followed by quenching in ice water, a Co-Ni-V-Al-based superalloy strengthened by the steady-state γ′ phase was obtained.

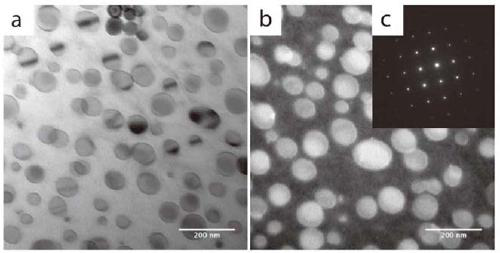

[0043] figure 2 Shown are the microstructure images of alloys of the present invention after solution treatment at 1200°C for 12 hours, quenching in ice water, and aging at 900°C for 45 hours: (a) Alloy 6 and (b) Alloy 20.

Embodiment 3

[0045] Weigh high-purity elemental materials such as Co, Ni, V, and Al according to the composition ratio shown in alloy 9 and 23 in Table 1; put the above-mentioned high-purity elemental materials weighed into an electric arc melting furnace, and gradually Increase the current to 50-300A, so that the raw materials are smelted evenly, and smelted into a Co-based superalloy ingot; in a high-purity argon atmosphere, put the above-mentioned cast material at 1200°C for solution treatment for 12 hours, and quench it in ice water; After aging treatment at ℃ for 4000 hours and ice-water quenching, a Co-Ni-V-Al-based superalloy strengthened by the steady-state γ′ phase is obtained.

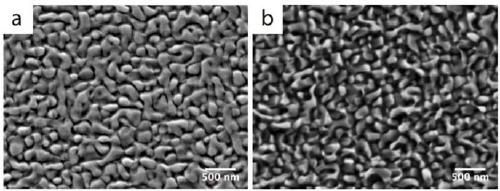

[0046] image 3 Shown are the microstructure images of alloys of the present invention after solution treatment at 1200°C for 12 hours, quenching in ice water, and aging at 900°C for 4000 hours: (a) Alloy 9 and (b) Alloy 23.

[0047] Figure 4 Shown are typical DSC heating curves for alloys of the inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com