Automatic scanning detection device and method for large-scale engineering mechanical structures

A mechanical structure and large-scale engineering technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of small and medium-sized enterprises that are not applicable to single-piece and small-batch product scanning inspections, detection robots are expensive, and affect scanning quality. Effects of reducing useless tracks, simple structure, and improving scanning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

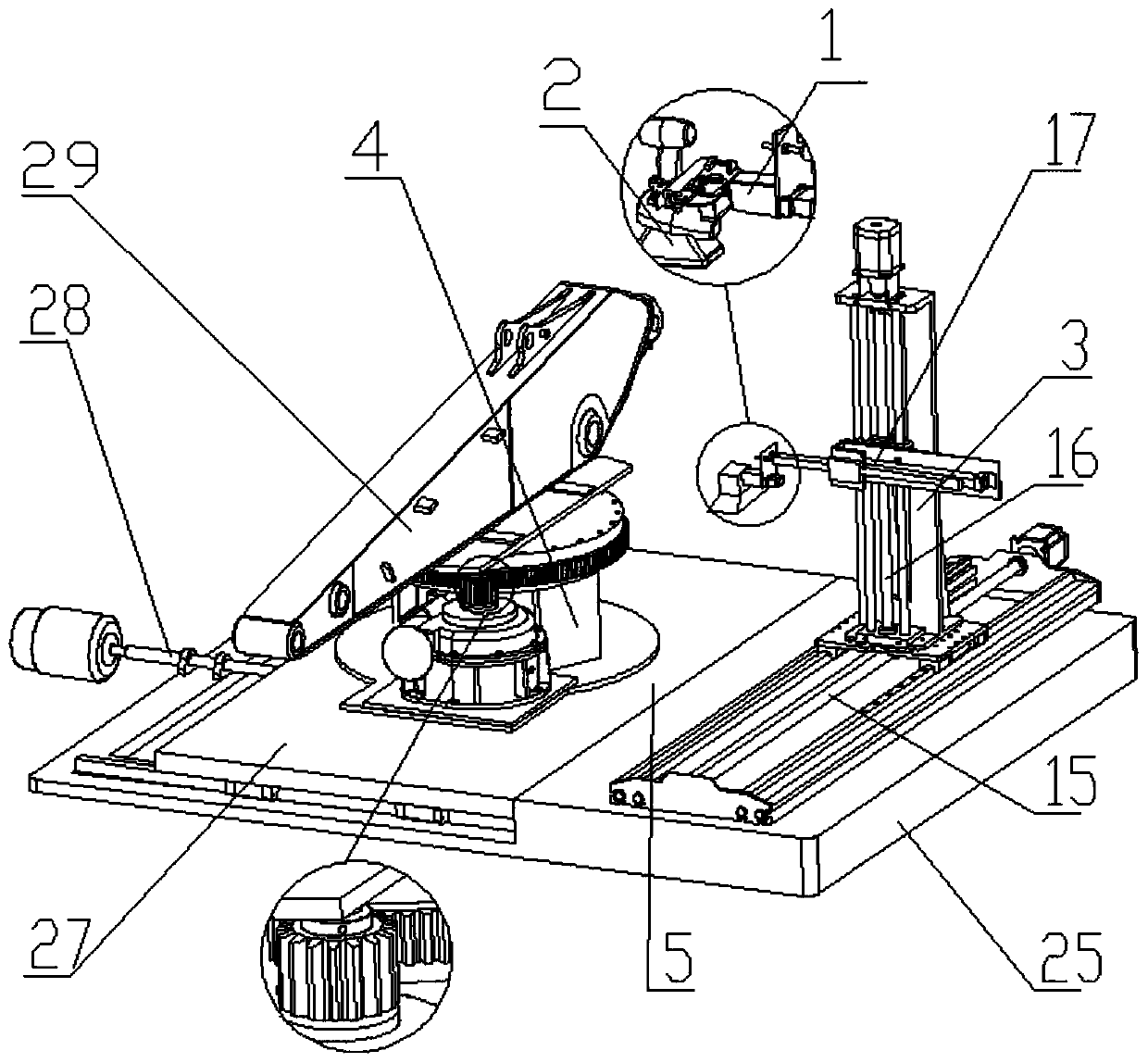

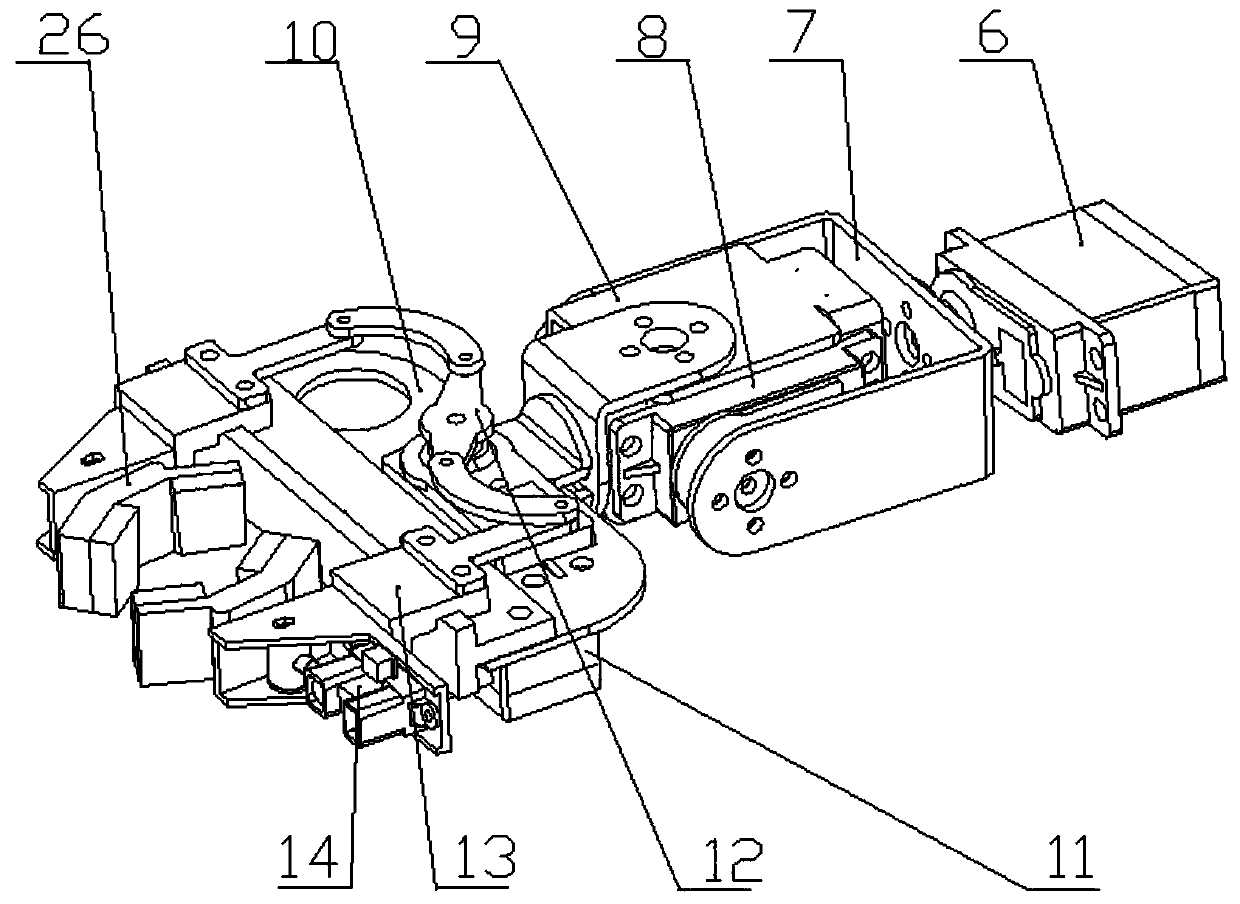

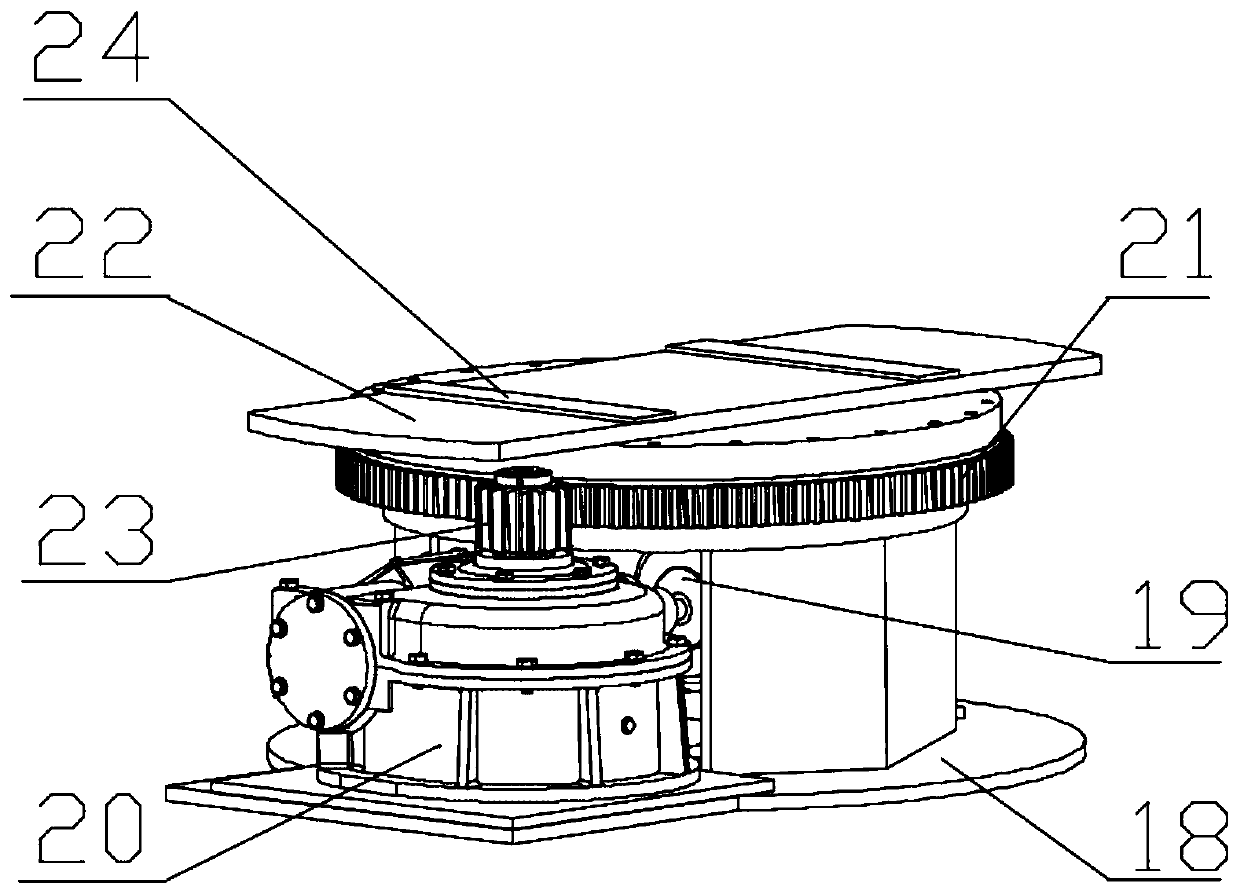

[0028] Such as Figure 1-3 As shown, an automatic scanning detection device and method for a large construction machinery structure, including a three-axis feed mechanism 3, a scanning clamping mechanism, a rotary mechanism 4 and a slide mechanism 5, the slide mechanism 5 includes a base 25 and a slide plate 27, the slide plate 27 is driven by the nut pair of the ball screw c28, the rotary mechanism 4 is arranged on the upper end surface of the slide plate 27, the three-axis feed mechanism 3 is arranged on the upper end surface of the base 25, and the top of the rotary mechanism 4 is connected with a positioning support plate 24 Arm 29; the three-axis feeding mechanism 3 is driven by the ball screw a15, the ball screw b16 and the linear cylinder 17, and the end of the three-axis feeding mechanism 3 is provided with a scanning and clamping mechanism; the scanning and clamping mechanism includes a 3D scanner 1 and the clamping mechanism 2, the 3D scanner 1 is placed in the middl...

Embodiment 2

[0032] Such as Figure 1-3 As shown, an automatic scanning detection device and method for a large construction machinery structure, including a three-axis feed mechanism 3, a scanning clamping mechanism, a rotary mechanism 4 and a slide mechanism 5, the slide mechanism 5 includes a base 25 and a slide plate 27, the slide plate 27 is driven by the nut pair of the ball screw c28, the rotary mechanism 4 is arranged on the upper end surface of the slide plate 27, the three-axis feed mechanism 3 is arranged on the upper end surface of the base 25, and the top of the rotary mechanism 4 is connected with a positioning support plate 24 Arm 29; the three-axis feeding mechanism 3 is driven by the ball screw a15, the ball screw b16 and the linear cylinder 17, and the end of the three-axis feeding mechanism 3 is provided with a scanning and clamping mechanism; the scanning and clamping mechanism includes a 3D scanner 1 and the clamping mechanism 2, the 3D scanner 1 is placed in the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com