Low-temperature air-cooled heat exchanger performance detection testbed

A technology of air-cooled heat exchangers and test benches, which is applied to the testing of machines/structural components, instruments, and measuring devices, which can solve the problems of heat exchanger performance testing, small testing range, and low precision, and prevent energy Loss, wind speed adjustment range is large, and the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

[0028] A low-temperature air-cooled heat exchanger performance detection test bench disclosed in the present invention combines a temperature and humidity adjustment device with a return-type wind tunnel to create an environment with low temperature and high humidity concentration, and is used to study the heat exchanger in this environment. Heater performance, especially observe and study the performance of the heat exchanger under frosting conditions, and check whether its resistance, heat transfer performance, and mechanical properties are up to standard.

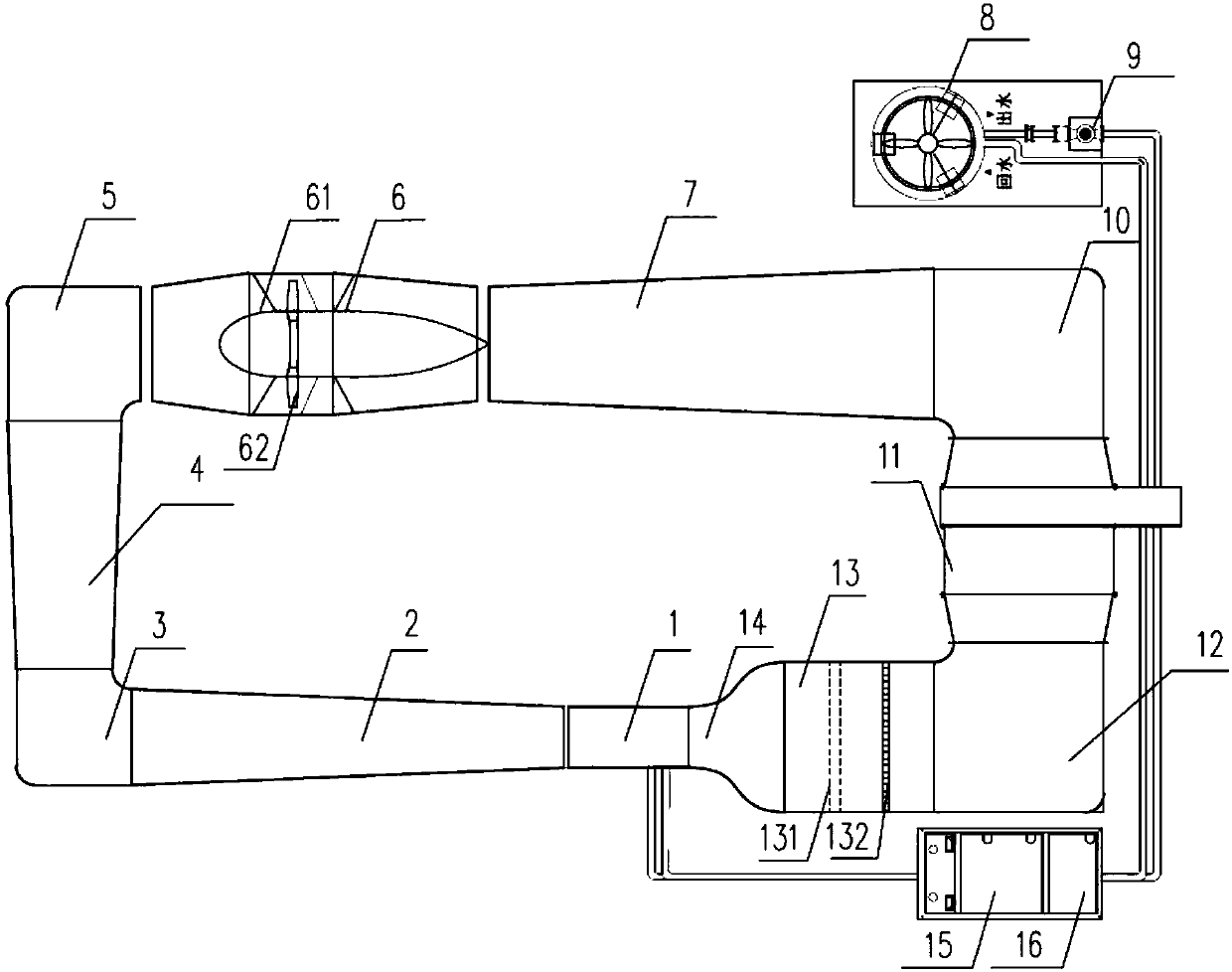

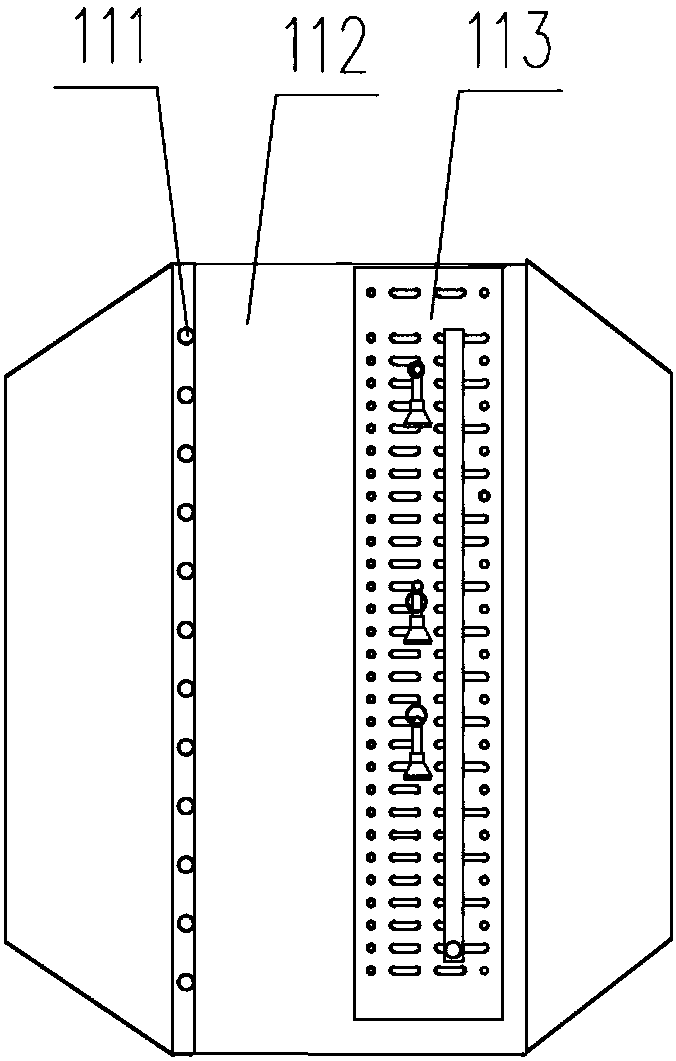

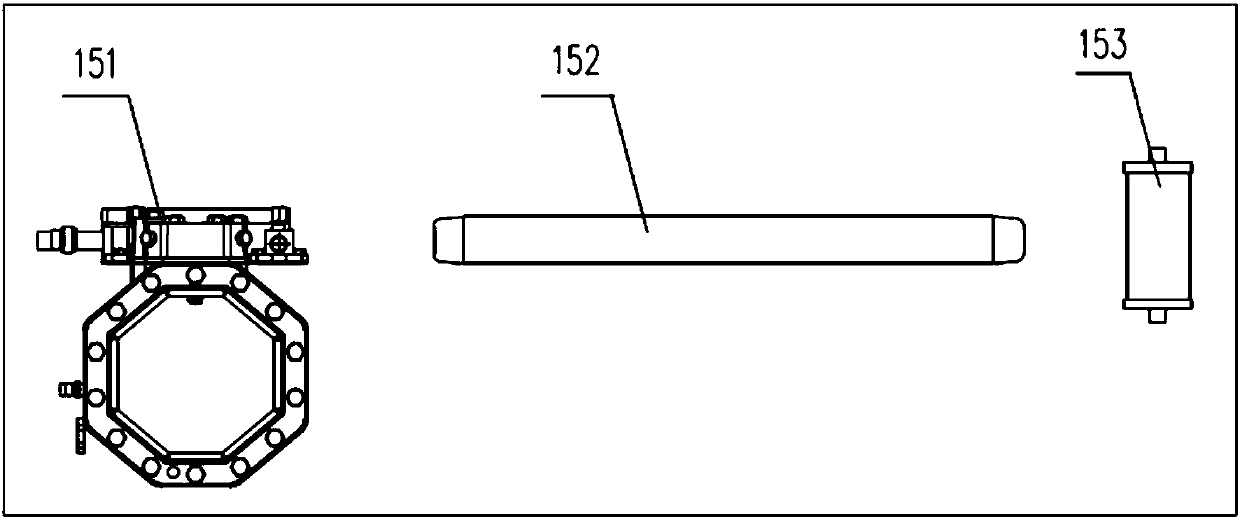

[0029] Such as figure 1 As shown, a low-temperature air-cooled heat exchanger performance test bench disclosed in the embodiment of the present invention includes a return-type wind tunnel, a temperature-humidity adjustment asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com