Refrigerating system quasi-explosion-proof nonmetallic insulation material compatibility test system

A technology for insulating materials and refrigeration systems, applied in the field of testing, can solve the problems of narrow coverage, limited convenience of operation, inconvenient test items for testing institutions compatibility, etc., to achieve real-time collection and reduce the weight of containers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

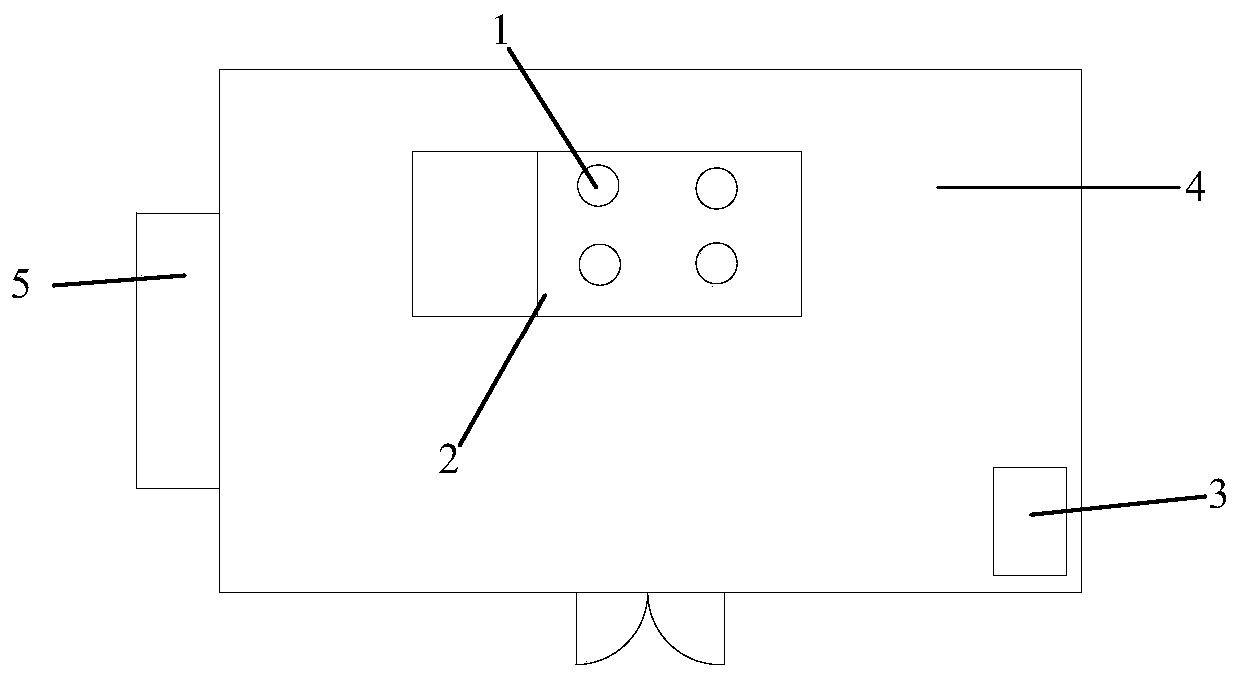

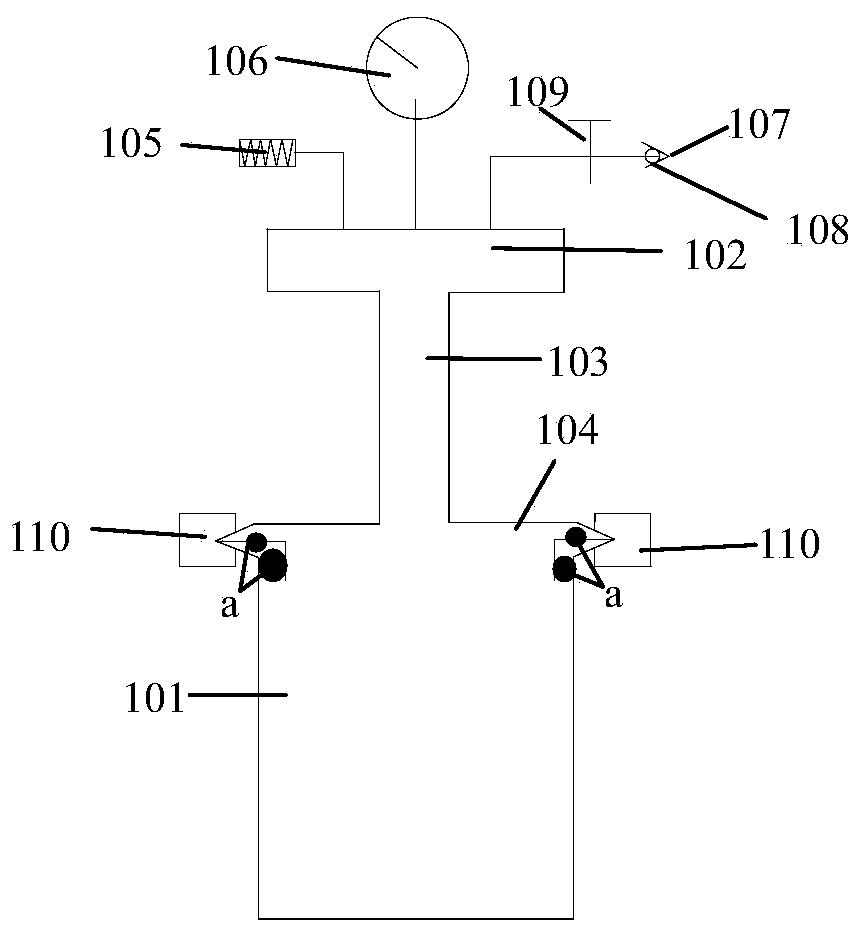

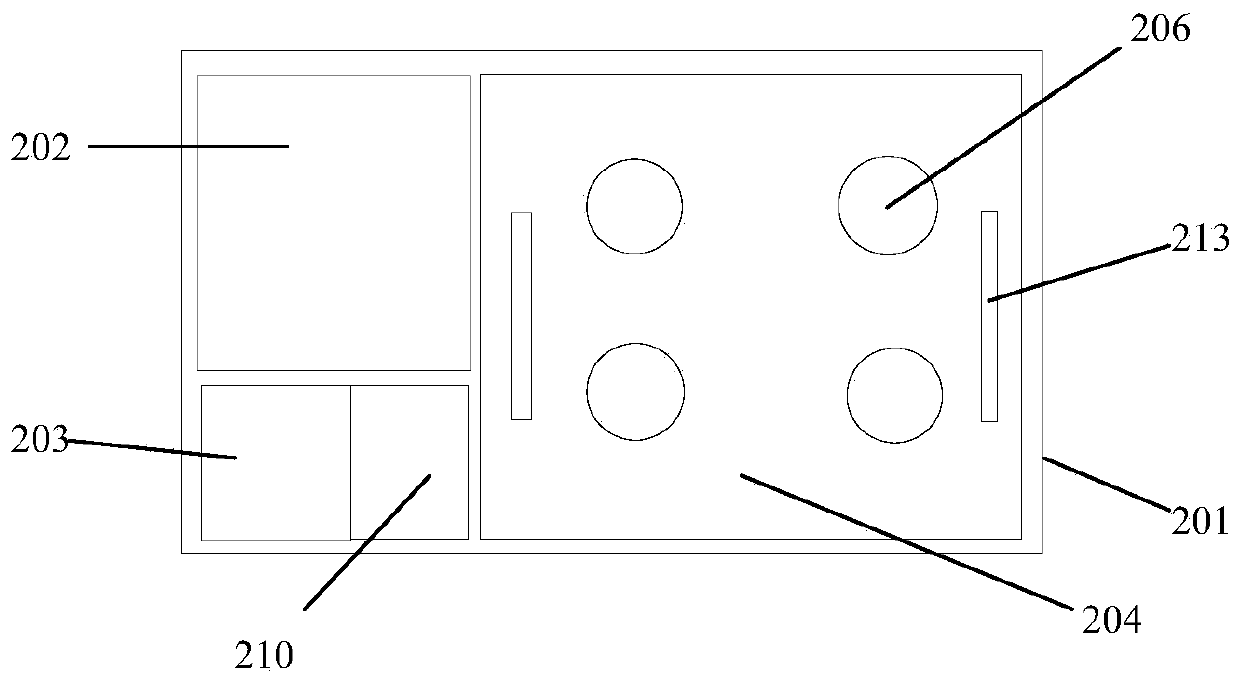

[0032] In order to solve the above-mentioned technical problems, the present invention is realized in the following manner, as shown in the figure: a refrigeration system quasi-explosion-proof non-metallic insulating material compatibility test system, which includes a pressure vessel 1, a constant temperature oil bath system 2, an evacuation and filling system System 3, quasi-explosion-proof environment system 4 and measurement and control system 5; evacuation and filling system 3 forms a vacuum and liquid filling connection with pressure vessel 1; constant temperature oil bath system 2 includes oil bath 206, and pressure vessel 1 is placed in oil bath 206 The constant temperature oil bath system 2 is placed in the quasi-explosion-proof environment system 4; the measurement and control system 5 monitors and controls and adjusts the environmental parameters of the quasi-explosion-proof environment system 4; the measurement and control system 5 forms a pressure and temperature da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com