Multi-source fault detection and diagnosis method and device

A technology of fault detection and diagnosis method, applied in the direction of comprehensive factory control, instrumentation, comprehensive factory control, etc., can solve the problems of not considering the intricate relationship of variables, single fault type, etc., to achieve the effect of rapid positioning and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

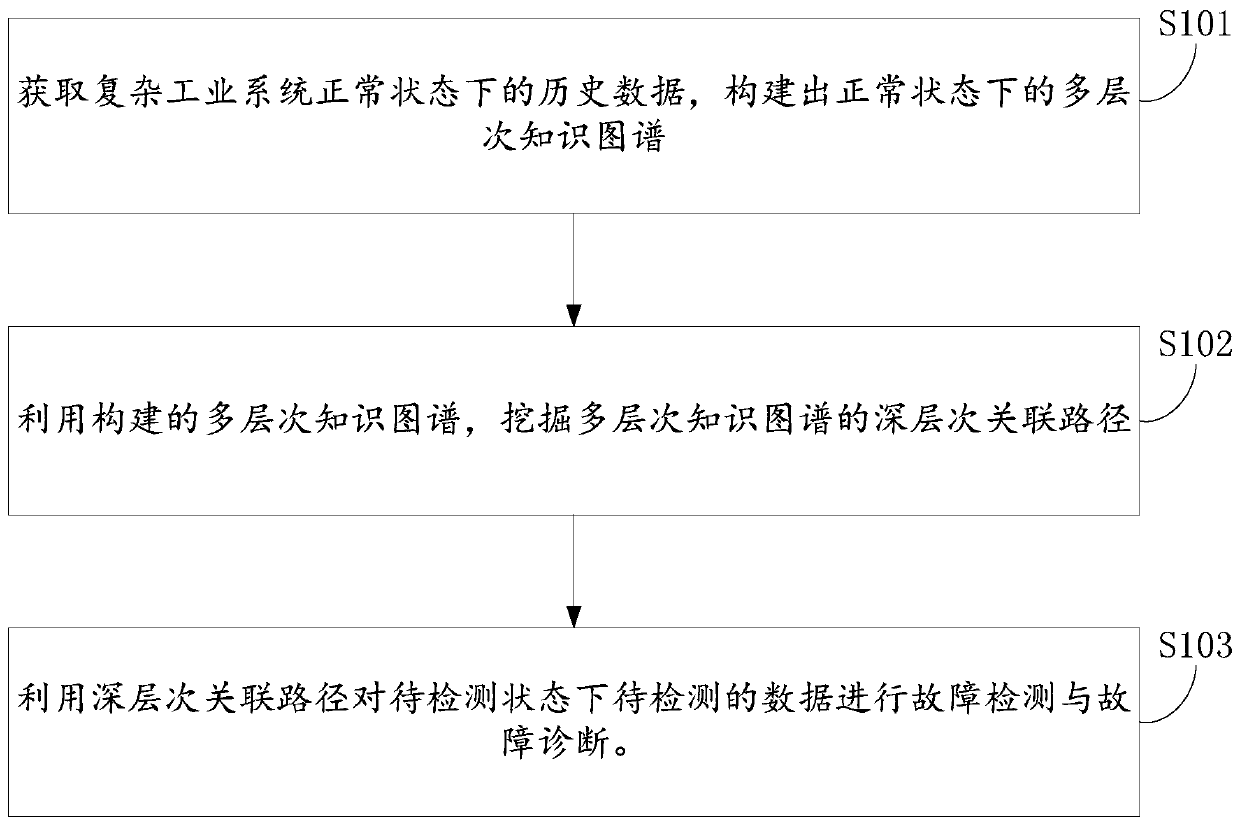

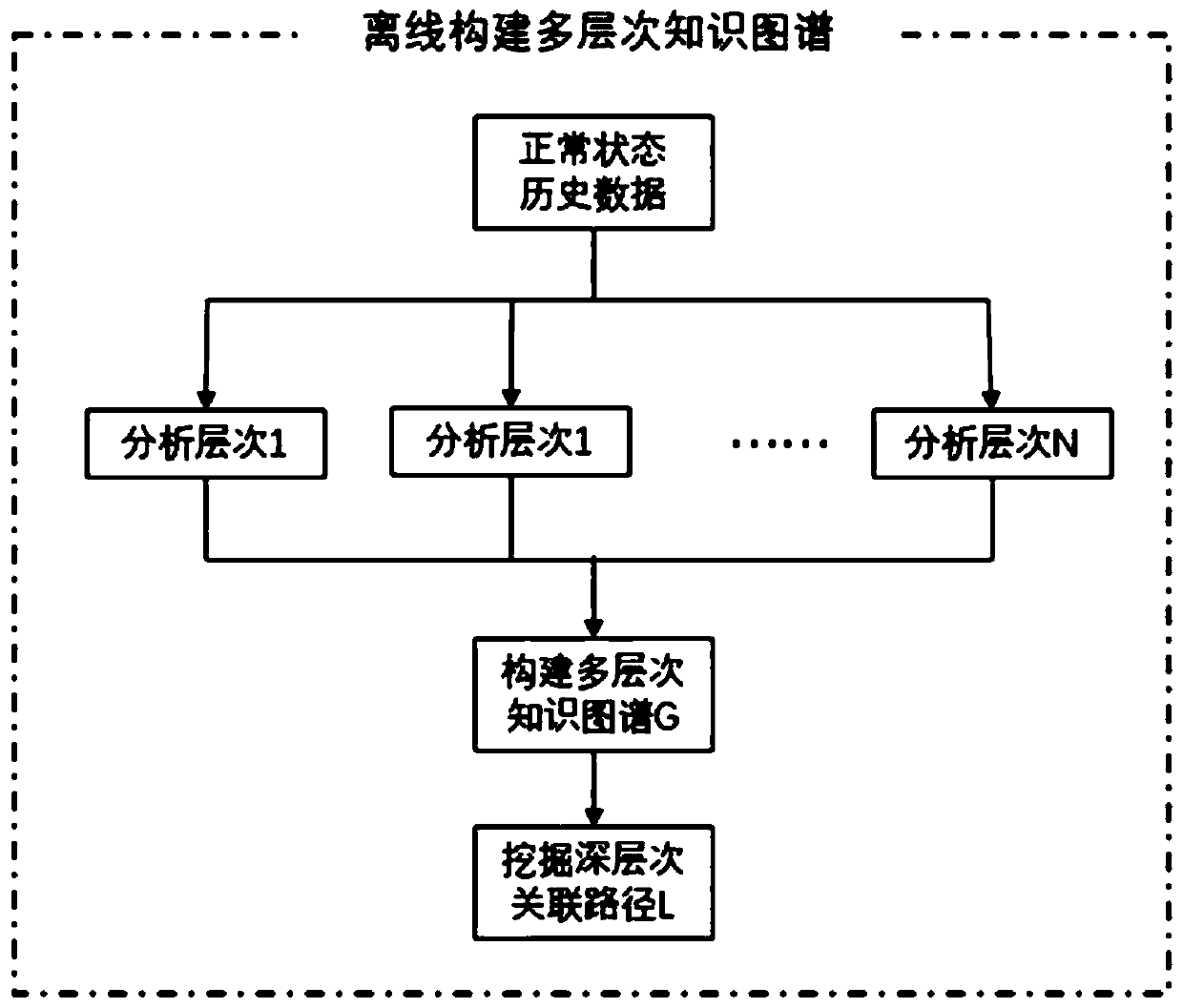

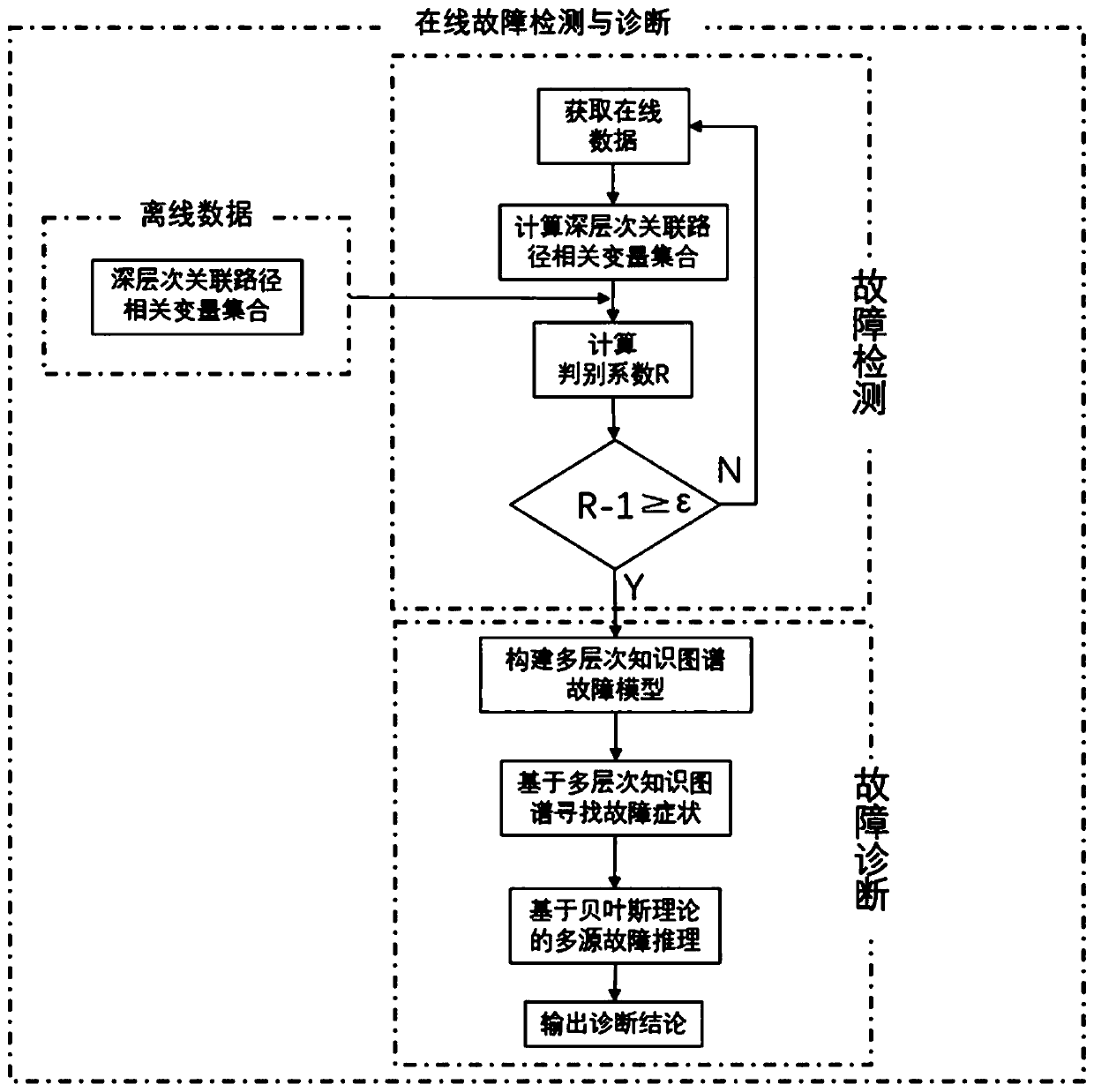

Embodiment 1

[0057] This embodiment provides a multi-source fault detection and diagnosis method based on multi-level knowledge graphs and Bayesian theoretical reasoning. Firstly, the historical data of complex industrial systems under normal conditions are used to analyze from different levels, and multi-level knowledge under normal conditions is constructed. Atlas, dig out the deep-level correlation path of the multi-level knowledge map in the normal state; obtain the data to be detected in the complex industrial system to be detected, calculate the discrimination coefficient R, and judge whether the system is in a fault state. If the system is in a fault state, enter Fault diagnosis stage; in the fault diagnosis stage, the system fault variables are determined according to the deep-level correlation path, and the multi-level knowledge graph fault model under the state to be detected is constructed according to the determined fault variables; the multi-level knowledge graph fault model is ...

Embodiment 2

[0127] This embodiment provides a multi-source fault detection and diagnosis device, which includes:

[0128] The deep-level correlation path acquisition module is used to obtain the historical data under the normal state of the system, construct the multi-level knowledge map under the normal state, and mine the deep-level correlation path of the multi-level knowledge map under the normal state; obtain the system under the current state to be detected For the data to be detected, construct a multi-level knowledge graph under the state of detection, and mine the deep-level correlation path of the multi-level knowledge graph under the state of detection;

[0129] A fault detection module is used to judge whether the data to be detected is in a fault state;

[0130] The fault diagnosis module is used to determine the fault variables if the system is in a fault state, and construct a multi-level knowledge map fault model under the state to be detected; use the multi-level knowledg...

Embodiment 3

[0157] A computer-readable storage medium, on which a computer program is stored, and when the program is executed by a processor, the steps in the above-mentioned multi-source fault detection and diagnosis method are realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com