Shunt integrated device for a multi-stack fuel cell engine system

An engine system and fuel cell technology, applied in fuel cells, electrochemical generators, circuits, etc., can solve the problems of difficult reduction in the size of the engine system, the large space occupied by pipelines, and the reduction of operating space, etc., to achieve simple, compact, Compact structure, convenient maintenance and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

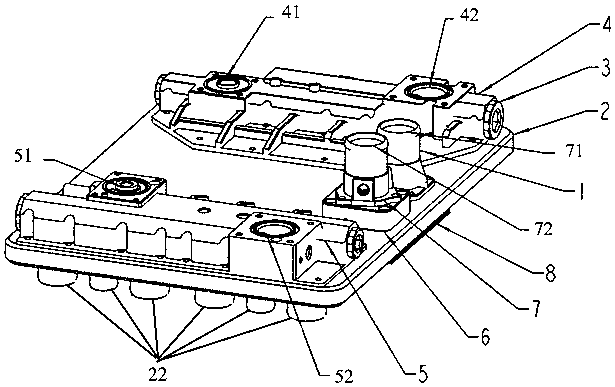

[0041] The present invention will be further described below in conjunction with the following embodiments. It should be understood that the following examples are only used to further illustrate the present invention, and cannot be interpreted as limiting the protection scope of the present invention. Non-essential improvements and adjustments all belong to the protection scope of the present invention. The specific process parameters and the like in the following examples are only examples of suitable ranges, that is, those skilled in the art can make a selection within a suitable range through the description herein, and are not limited to the specific values exemplified below. In each figure, the same or corresponding reference numerals denote the same components, and repeated explanations will be omitted.

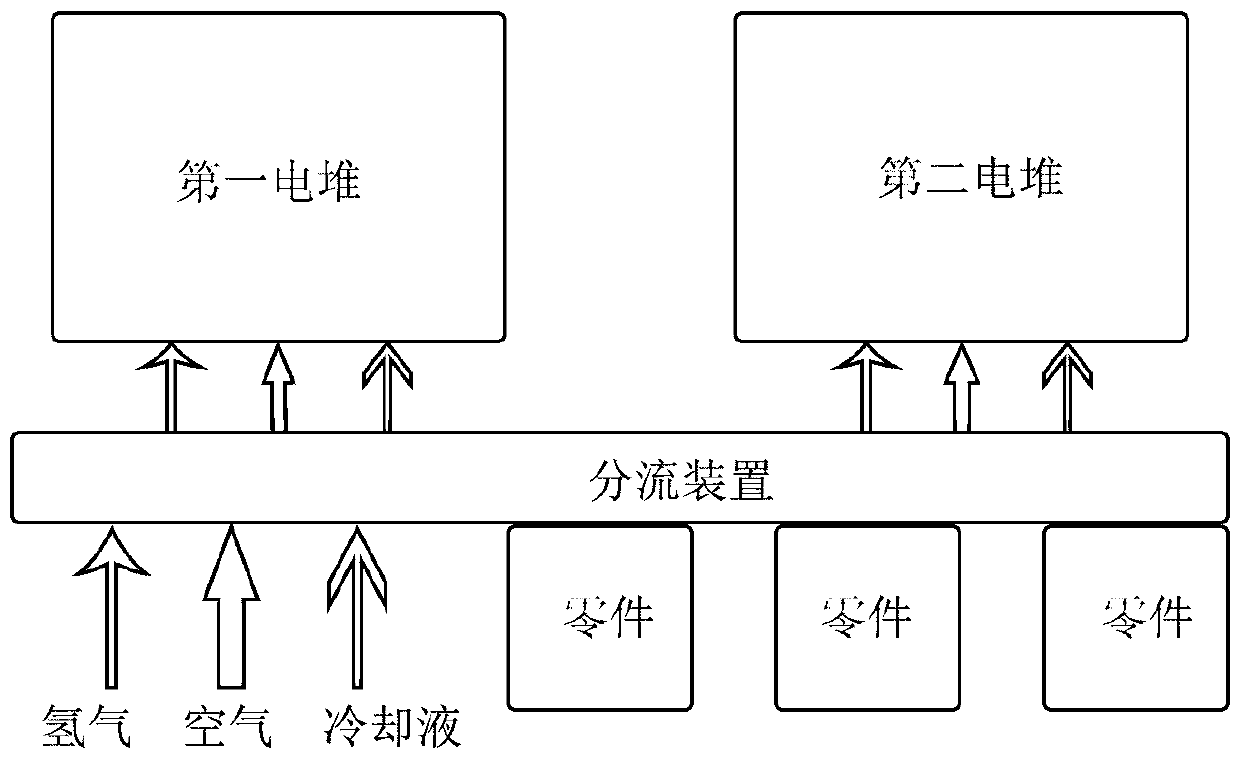

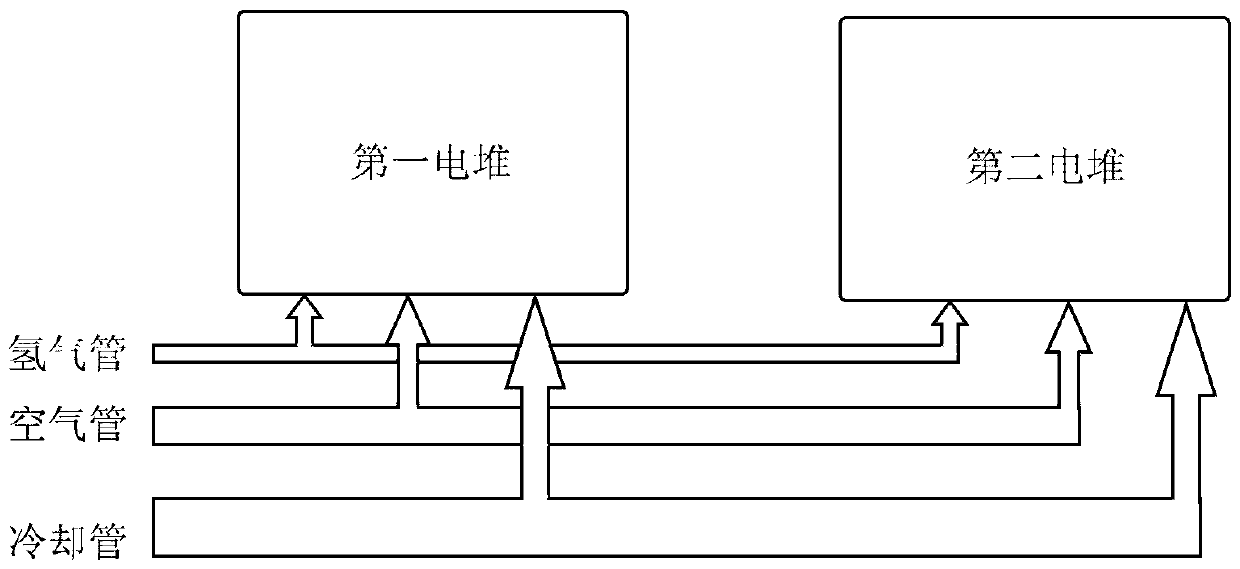

[0042] Disclosed here is a flow distribution integration device for a multi-stack fuel cell engine system, including: a flow distribution plate 2 used for system loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com