Harmonic filter maintenance device

A harmonic filter and maintenance device technology, applied to harmonic reduction devices, DC circuits to reduce harmonics/ripples, AC networks to reduce harmonics/ripples, etc., can solve problems such as prone to failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

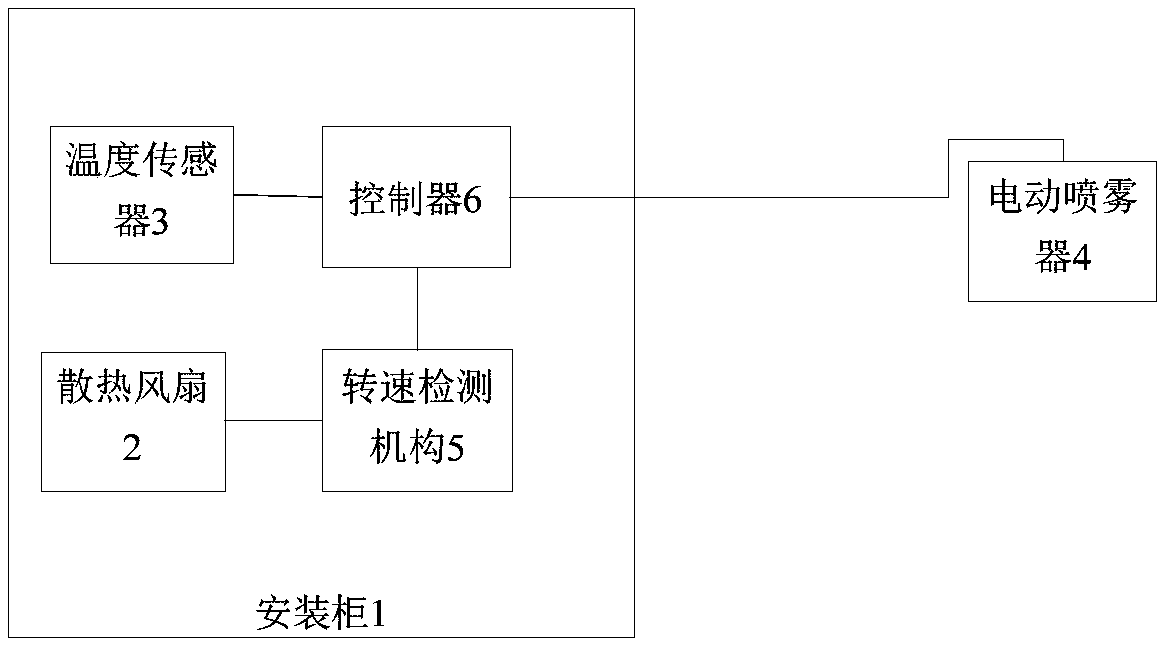

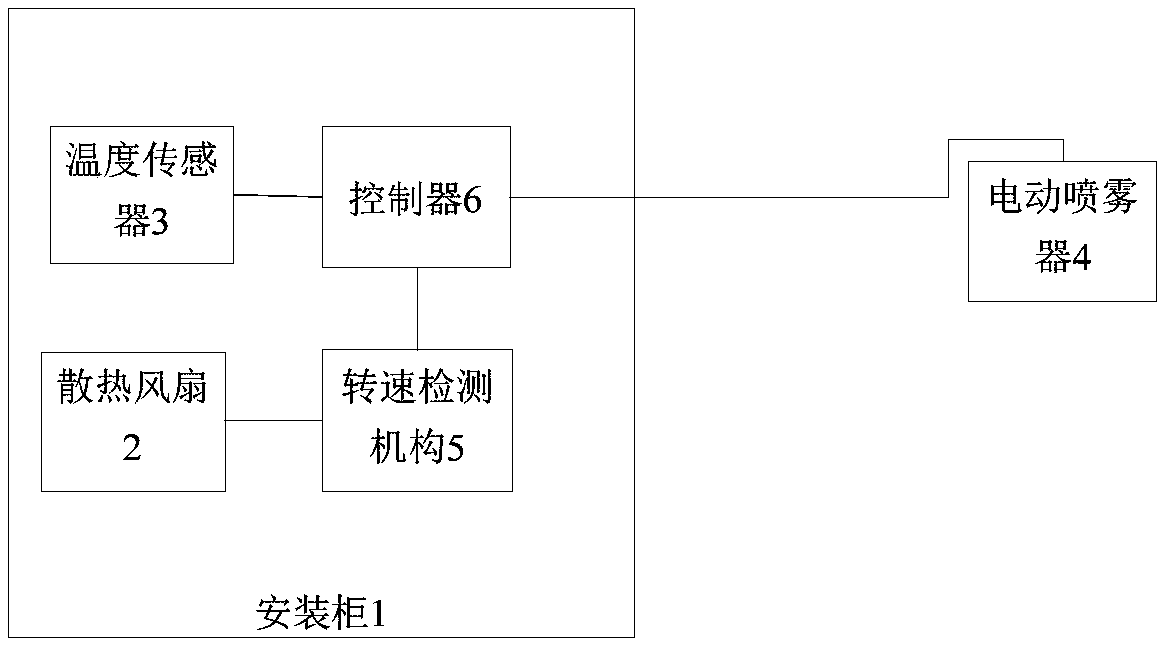

[0022] A harmonic filter maintenance device, including a filter installation cabinet 1, the installation cabinet 1 is equipped with a cooling fan 2 and a temperature sensor 3, the device also includes an electric sprayer 4, the electric sprayer 4 is equipped with insulating cooling liquid, and the nozzle is facing downwards Stretch into installation cabinet 1 top, the motor of cooling fan 2 is connected with speed detection mechanism 5, and speed detection mechanism 5 is a speed sensor, and speed sensor and temperature sensor 3 are connected with the switch of electric sprayer 4 by controller 6 respectively.

[0023] There are two cooling fans 2, which are respectively connected with the controller 6, one as the main fan and the other as the standby fan.

[0024] The installation cabinet 1 is a metal cabinet.

[0025] The motor of electric sprayer 4 is connected with solar panel, as auxiliary power supply.

[0026] The speed detection mechanism 5 is connected with a wireless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com