Reinforcing cage manufacturing device and method

A technology for manufacturing devices and steel cages, which is applied in the field of building structures, can solve the problems of low manufacturing efficiency, time-consuming and labor-intensive processing, etc., and achieve the effect of high manufacturing efficiency and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

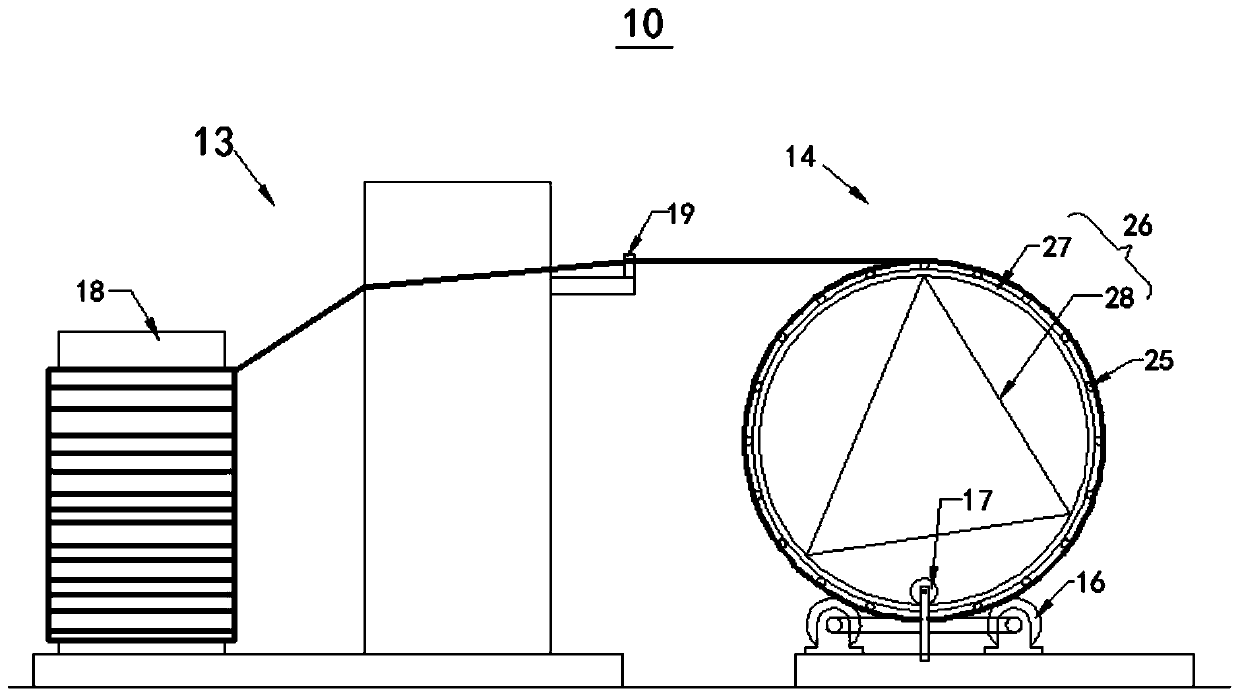

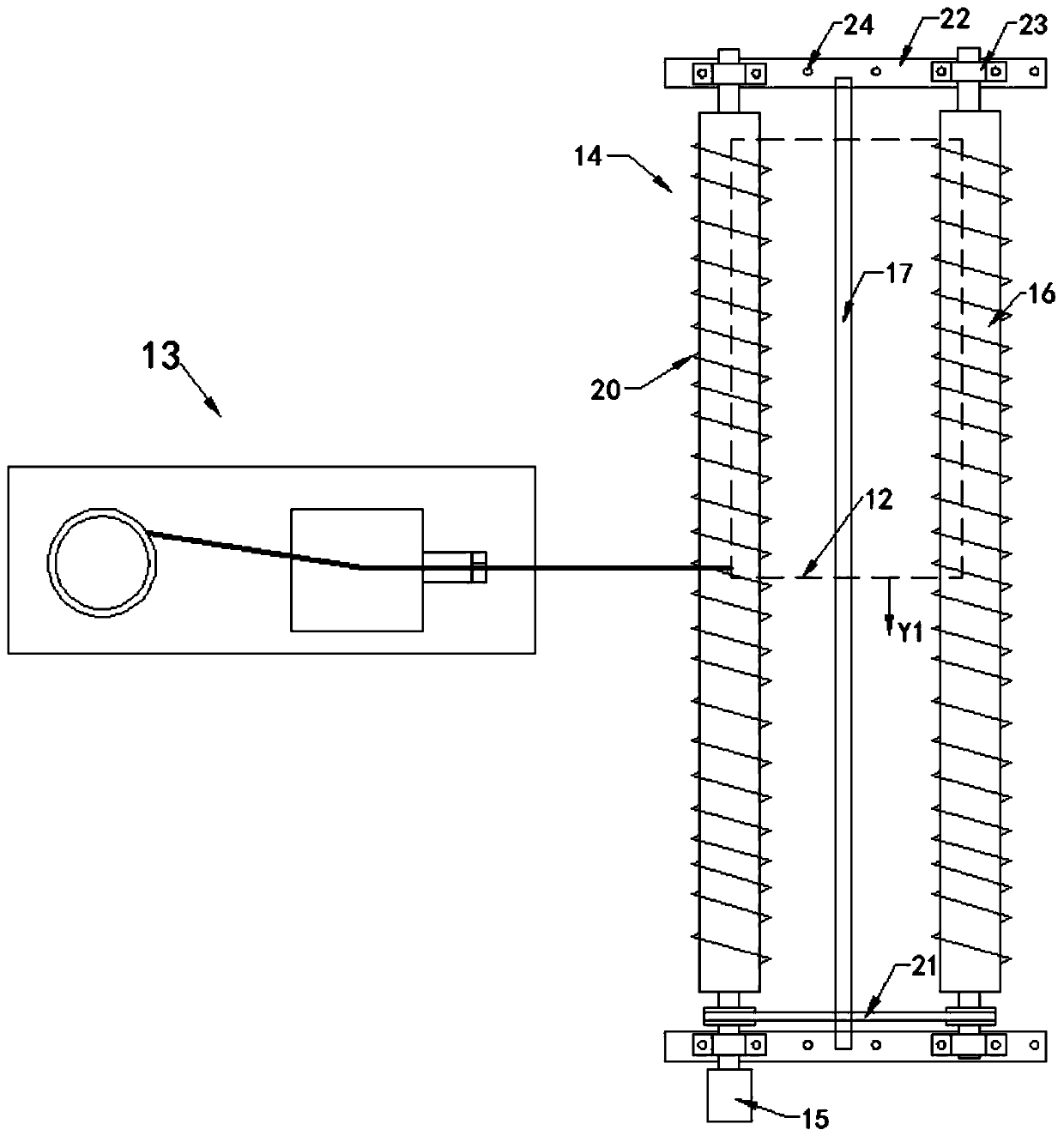

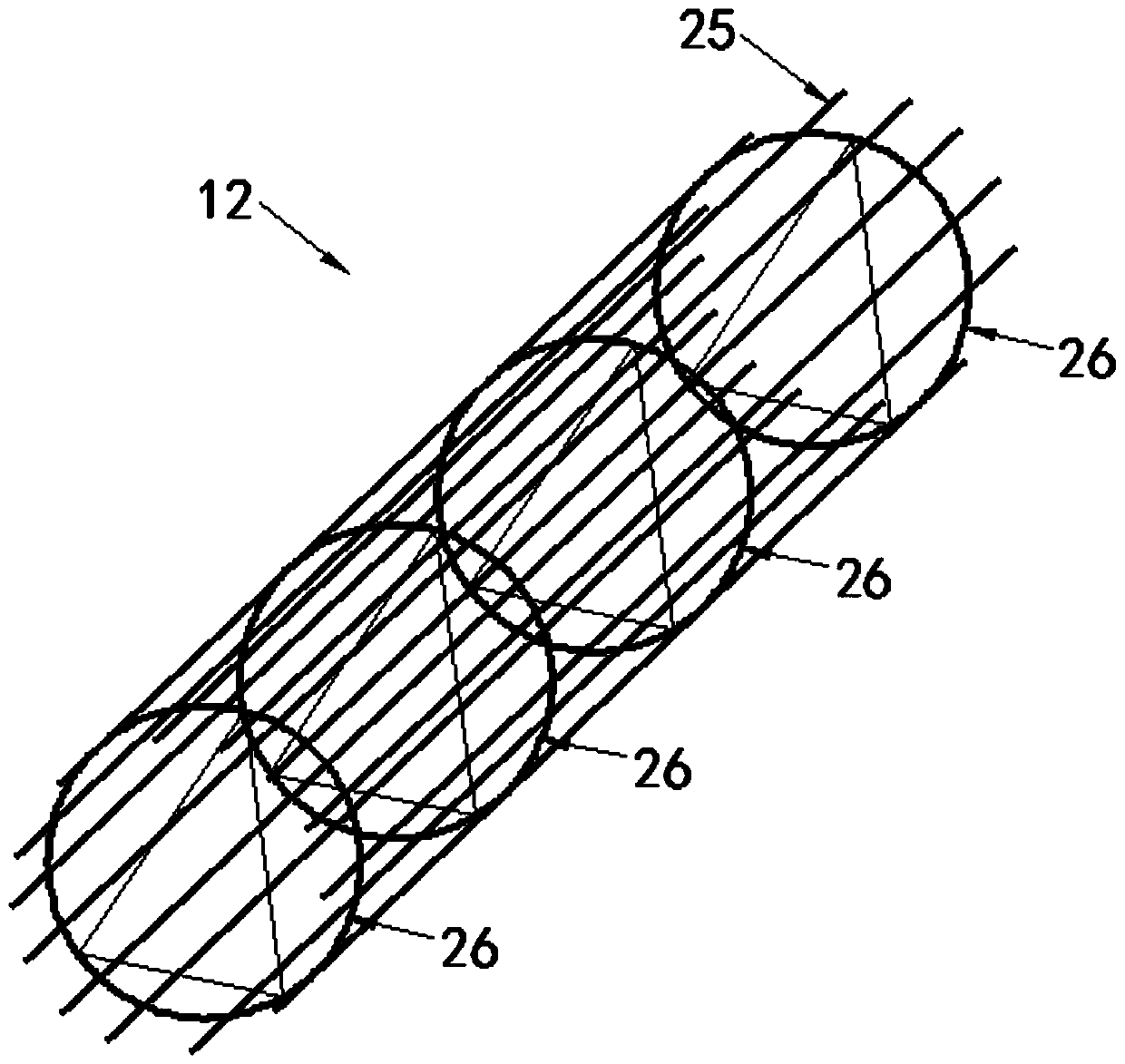

[0032] see figure 1 , figure 2 , the embodiment of the present invention provides a kind of reinforcement cage making device 10, is used for the inner reinforcement cage 12 (seeing in image 3 ) to wind the outer steel mesh 11 (see Figure 4 ) operation, which includes feeding device 13 and winding device 14. The winding device 14 includes a driver 15, two rollers 16 and a pressure roller 17; the two rollers 16 are horizontally arranged in parallel and spaced apart, so that the inner reinforcement cage 12 can be supported on the two with its outer circumference tangentially; optional , The two ends of the roller 16 are provided with a base 22, the base 22 is connected with a bearing seat 23, and the two ends of the two rollers 16 are respectively rotatably supported on the bearing seat 23. The base can be fixedly connected to the ground. Optionally, the base 22 is elongated, its length is perpendicular to the axis of the roller 16, and the base 22 is distributed with a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com