Z-axis falling prevention control device of gantry three-dimensional printer

A three-dimensional printer and control device technology, which is applied to manufacturing auxiliary devices, processing data acquisition/processing, additive processing, etc., can solve problems such as brake action delay, scrap parts, equipment platform and print head damage, etc. High, low cost, no security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

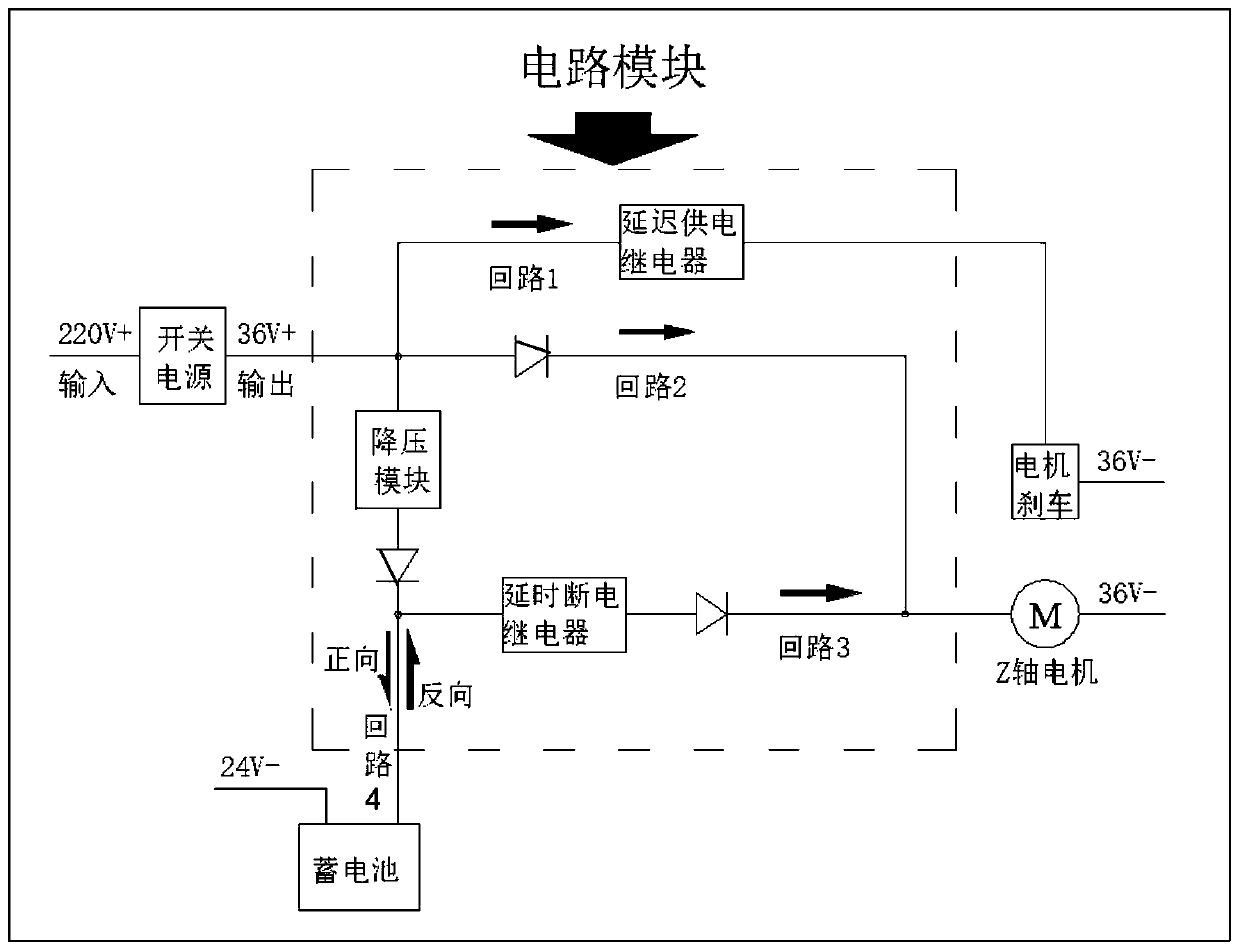

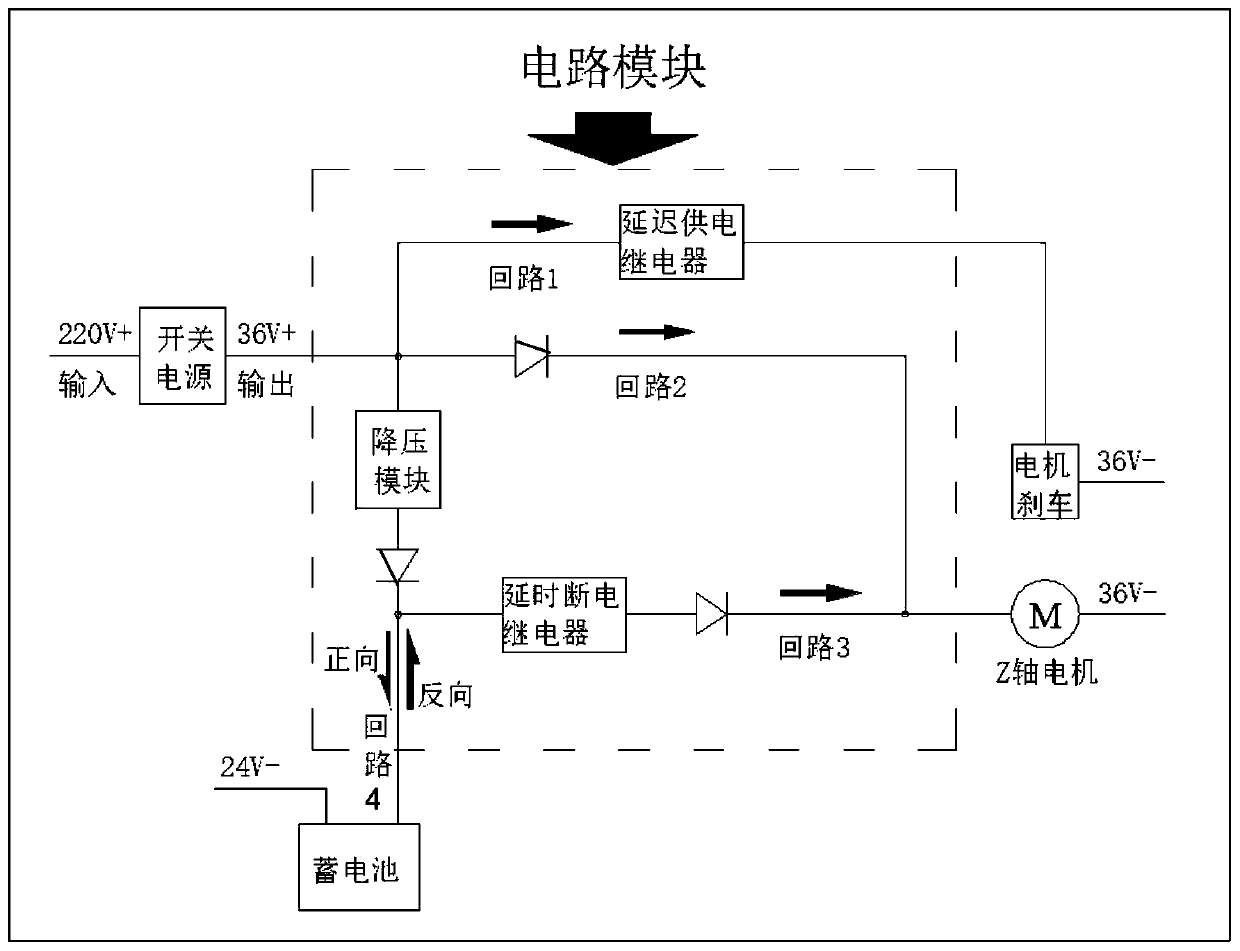

[0015] like figure 1 As shown, the anti-drop control device provided by the present invention includes a switching power supply, a battery, and a circuit module. Through the coordination of the switching power supply, the battery, and the circuit module, the motor brake can delay the release of the brake pads when the 3D printer is turned on. Avoid the problem of Z-axis beam drop caused by the delay of motor power-on self-locking; the motor will continue to be powered by the battery for a short time at the moment of power failure, and avoid the problem of Z-axis drop caused by the delay of brake pads; thus ensuring that the gantry 3D printer can be turned on and off And when there is a sudden power failure, the Z-axis beam can maintain a stable state, which can effectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com