Automatic edge attaching device for filter element

A welting and automatic technology, applied to cardboard items, etc., can solve problems such as troublesome machine adjustment, failure to make a difference, and no prospect, etc., to achieve the effect of increasing productivity, reducing product cost, and improving aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

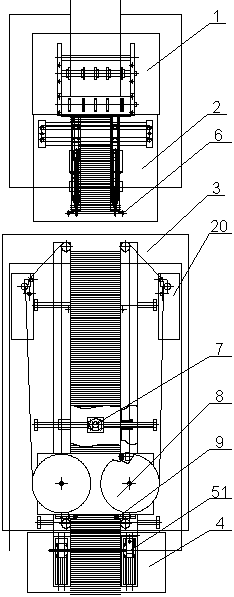

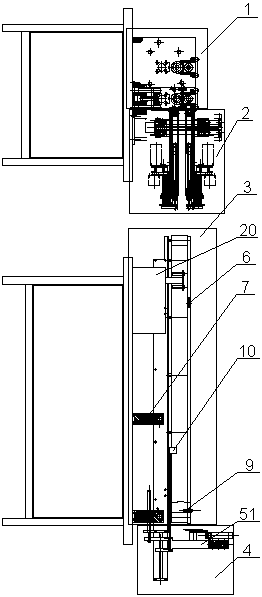

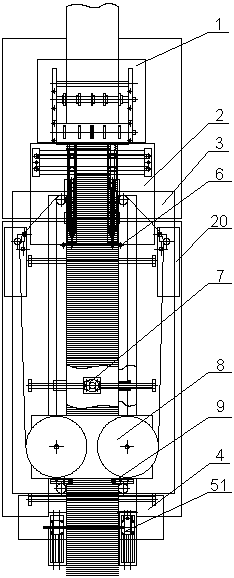

[0025] figure 1 , figure 2 middle, image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 Among them, the filter element automatic welting device is composed of paper feeding device (1), paper delivery device (2), welting device (3), and cutting device (4). In fact, paper delivery device (2) is responsible for paper delivery, and at the same time Fold the paper evenly, and clamp a part of it in the middle of the welting device (3) so that the side strips can be pasted according to the spacing of the delivery device. Edge bar is pulled out from edge bar seat (8) and then to welting device (3) after gluing device (20) gluing. Among them, the paper delivery device and the welting device adopt a linkage method, that is, the paper delivery screw (31) of the paper delivery device turns a circle and the welting device (3) drives the side strip to move the distance required by the product spacing; specifically, the paper feeding device and the weltin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com