New energy automobile wheel edge split-type driving assembly

A technology for driving assemblies and automobile wheels, applied in motion deposition, control devices, power devices, etc., can solve problems affecting applicability and safety, poor design of wheel motor suspension, etc., to achieve wide applicability, adjustment Simple, efficient results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

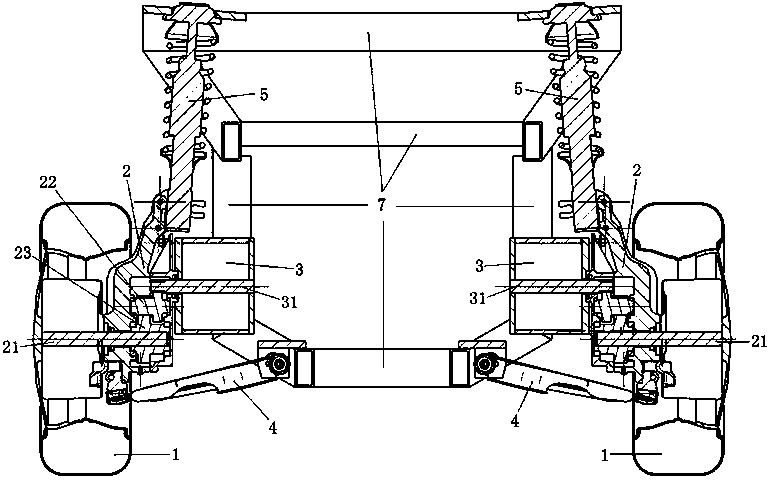

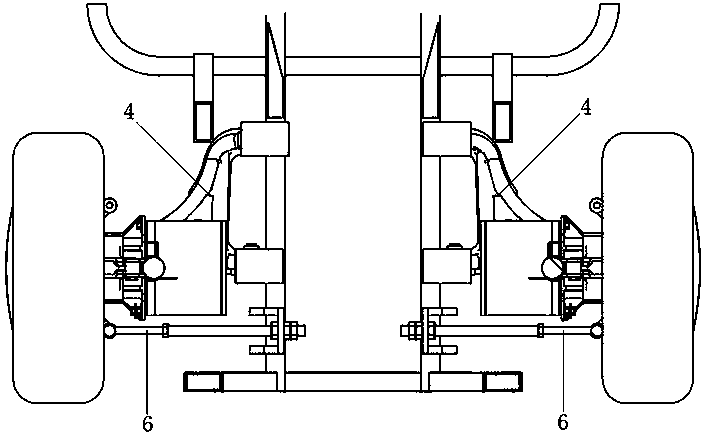

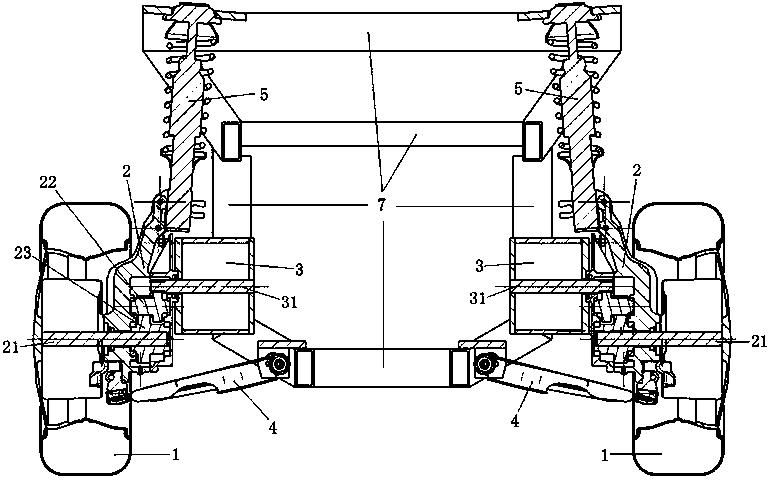

[0020] Such as figure 1 with figure 2 As shown, a new energy vehicle wheel-side split drive assembly includes a frame 7 and a wheel 1, and the assembly also includes a suspension gearbox arranged on the inner side of the hub of the wheel 1 on both sides and symmetrically arranged left and right. 2 and a motor 3, the motor shaft 31 of the motor 3 is connected to and drives the drive shaft 21 through the gear set in the suspension gearbox 2, and the drive shaft 21 is connected to and drives the hub of the wheel 1.

[0021] The box body of the suspension gearbox 2 is connected with the vehicle frame 7 through a McPherson independent suspension to form a vehicle drive system.

[0022] The McPherson independent suspension includes a rocker bracket 4, a suspension shock absorber 5 and a positioning rod 6, and the lower end of the box bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com