Variable speed ratio steering system based on cross shaft universal joint

A cross-shaft universal and steering system technology, applied in the field of variable-speed ratio steering systems, can solve the problems of high manufacturing cost and time-consuming manufacturing, and achieve the effects of simple structure, reduced manufacturing cost, and improved steering portability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

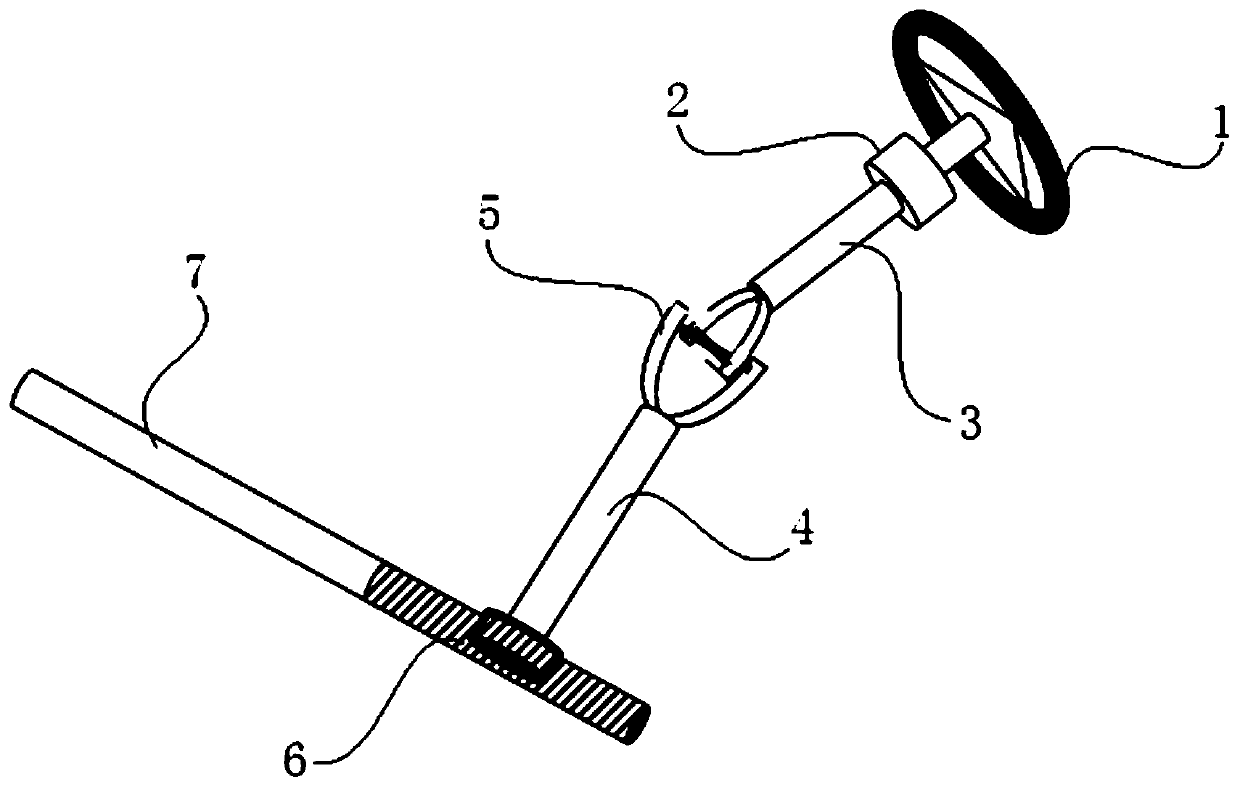

[0039] see figure 1 and figure 2 , the present embodiment discloses a variable speed ratio steering system based on cross-axis universal joints, including a steering wheel 1, a primary reduction mechanism 2, a steering column 3, a cross-axis universal joint transmission mechanism, a steering transmission shaft 4 and a steering gear.

[0040] The primary reduction mechanism 2 is a primary constant speed ratio reducer. The input end of the primary reduction mechanism 2 is connected to the output end of the steering wheel 1 , and the output end of the primary reduction mechanism 2 is connected to the input end of the steering column 3 . That is, the input shaft of the primary constant speed reducer is connected to the output shaft of the steering wheel 1 , and the output shaft of the primary constant speed reducer is connected to the input shaft of the steering column 3 .

[0041] The angle at which the steering column 3 rotates is recorded as When the steering wheel 1 is i...

Embodiment 2

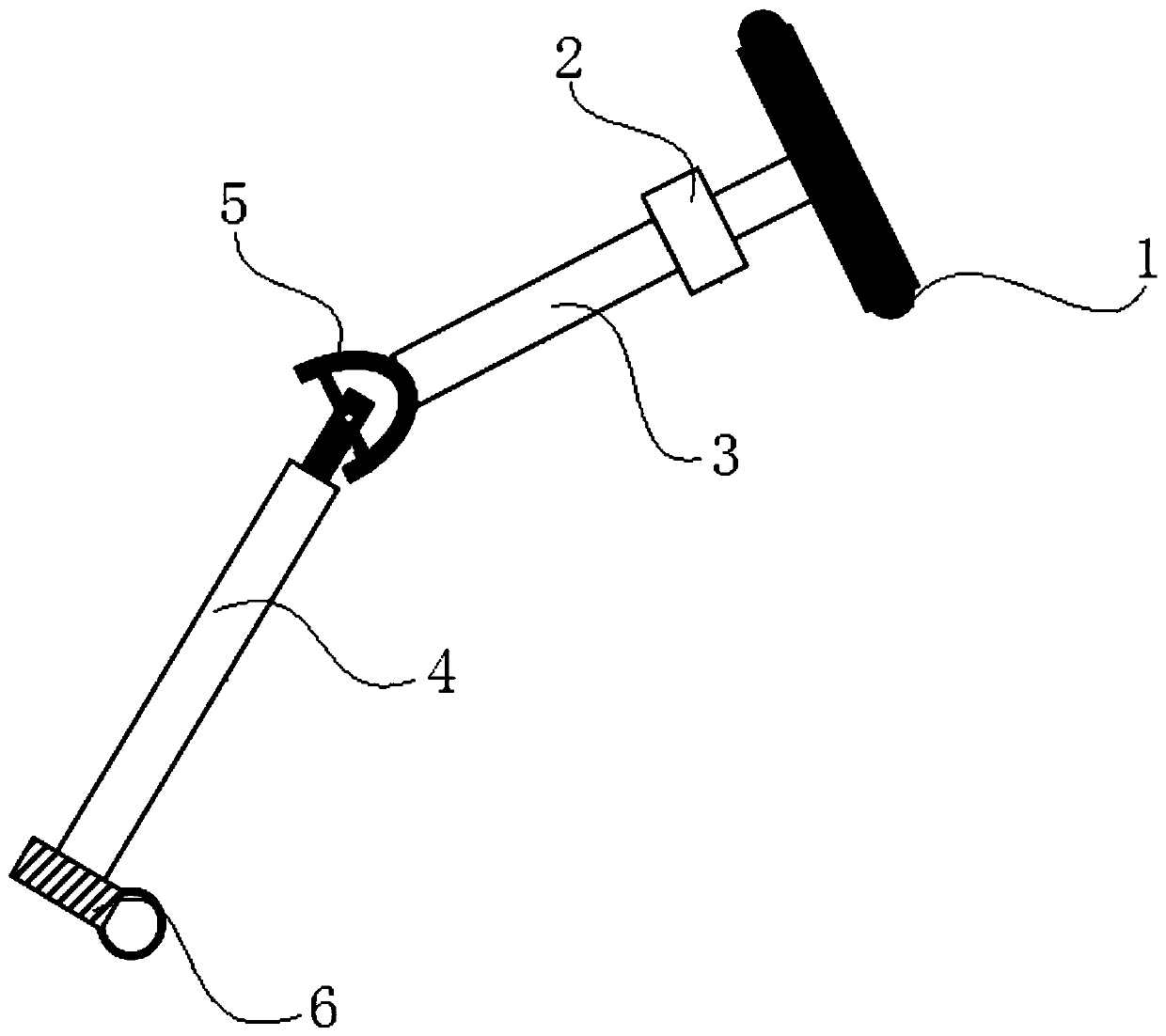

[0055] see image 3 and Figure 4 , the present embodiment discloses a variable speed ratio steering system based on cross-axis universal joints, including a steering wheel 1, a primary reduction mechanism 2, a steering column 3, a cross-axis universal joint transmission mechanism, a steering transmission shaft 4 and a steering gear.

[0056] The primary reduction mechanism 2 is a primary constant speed ratio reducer. The input end of the primary reduction mechanism 2 is connected to the output end of the steering wheel 1 , and the output end of the primary reduction mechanism 2 is connected to the input end of the steering column 3 . That is, the input shaft of the primary constant speed reducer is connected to the output shaft of the steering wheel 1 , and the output shaft of the primary constant speed reducer is connected to the input shaft of the steering column 3 .

[0057] The angle at which the steering column 3 rotates is recorded as When the steering wheel 1 is in...

Embodiment 3

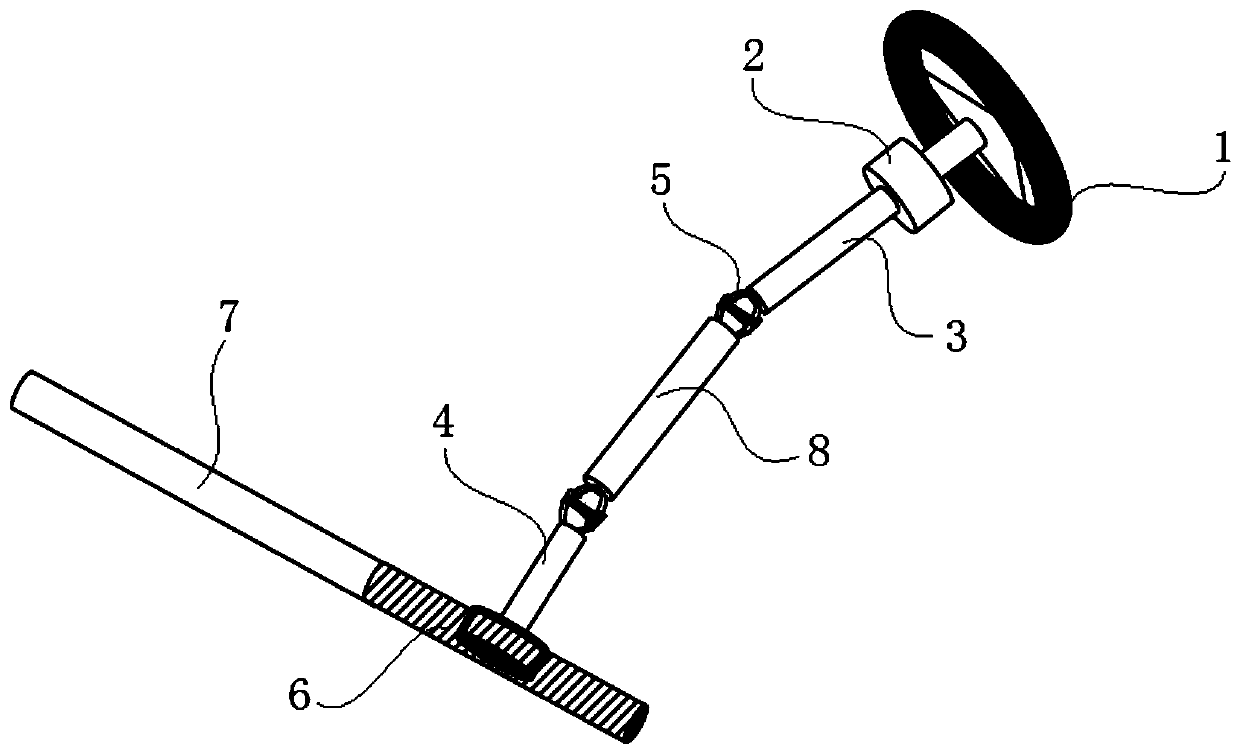

[0072] see Figure 5 and Figure 6 , the present embodiment discloses a variable speed ratio steering system based on cross-axis universal joints, including a steering wheel 1, a primary reduction mechanism 2, a steering column 3, a cross-axis universal joint transmission mechanism, a steering transmission shaft 4 and a steering gear.

[0073] The primary reduction mechanism 2 is a primary constant speed ratio reducer. The input end of the primary reduction mechanism 2 is connected to the output end of the steering wheel 1 , and the output end of the primary reduction mechanism 2 is connected to the input end of the steering column 3 . That is, the input shaft of the primary constant speed reducer is connected to the output shaft of the steering wheel 1 , and the output shaft of the primary constant speed reducer is connected to the input shaft of the steering column 3 .

[0074] The angle at which the steering column 3 rotates is recorded as When the steering wheel 1 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com