A zero-discharge treatment process for industrial cleaning wastewater

An industrial cleaning and treatment process technology, applied in the field of water treatment, can solve the problem of no better treatment method for wastewater, achieve the effects of reducing surface organic pollution, improving operation stability, and reducing organic pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

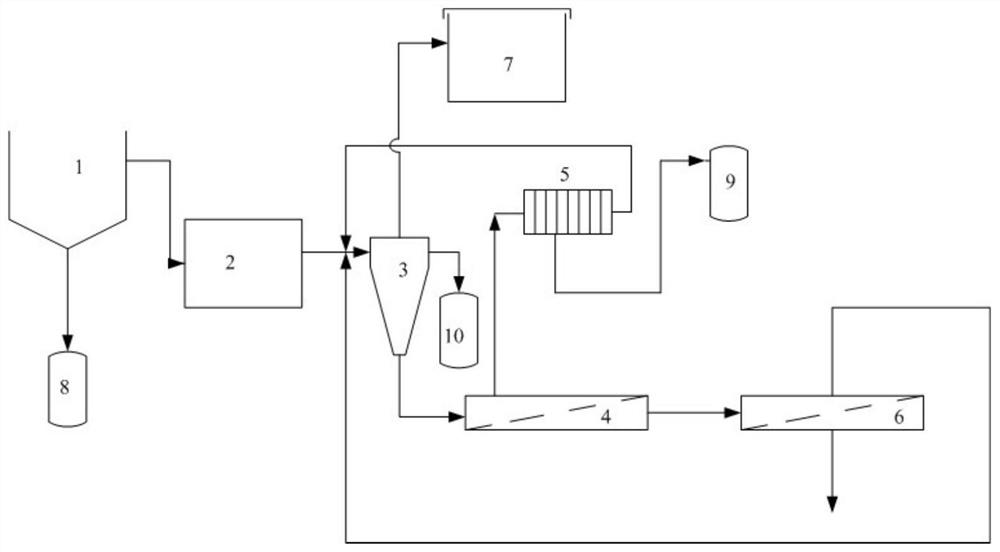

Method used

Image

Examples

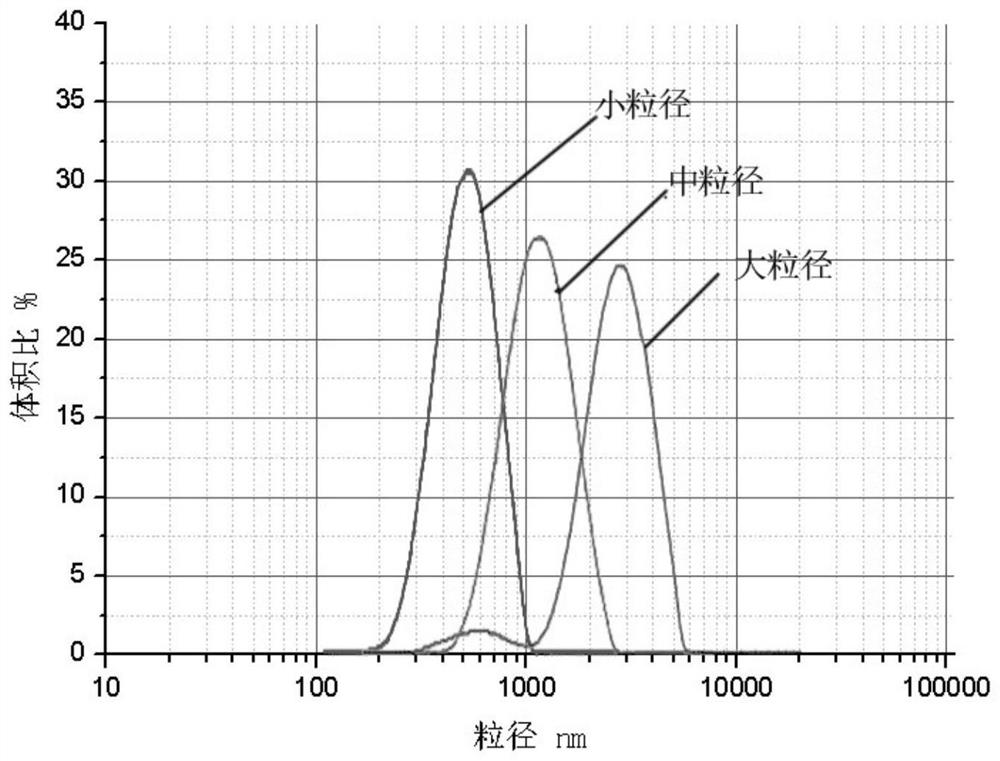

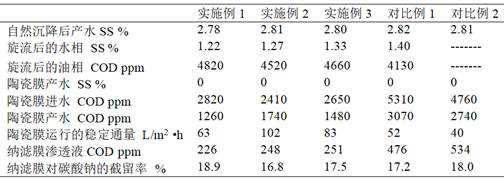

Embodiment 1

[0053] The cleaning waste liquid on the surface of the cut silicon wafer is first subjected to natural sedimentation treatment. The large particle silicon powder obtained at the bottom and the sedimentation supernatant are sent to the ozone reaction tank, and treated at 40°C and 1200-1500ppm concentration of ozone for 40 minutes, and then Send it to the oil-water-solid three-phase cyclone separator for separation treatment. In the separator, the flow rate of the feed is adjusted to 5min / s. The top is the oil phase outlet, the side is the solid phase outlet, and the bottom is the water phase outlet. The pressure at the outlet is 0.5MPa, the pressure at the outlet of the solid phase is 0.1MPa, and the volume ratio of the materials at the outlet of the oil phase, the outlet of the solid phase and the outlet of the water phase is adjusted to 1:3:20, and the oil phase at the top is sent to the biochemical system for further processing. Degradation treatment, the silicon powder with ...

Embodiment 2

[0055] The cleaning waste liquid on the surface of the cut silicon wafer is first subjected to natural sedimentation treatment. The large particle silicon powder obtained at the bottom and the sedimentation supernatant are sent to the ozone reaction tank, and treated at 35°C and 1200-1500ppm concentration of ozone for 50 minutes, and then Send it to the oil-water-solid three-phase cyclone separator for separation treatment. In the separator, the flow rate of the feed is adjusted to 8min / s. The top is the oil phase outlet, the side is the solid phase outlet, and the bottom is the water phase outlet. The pressure at the outlet of the solid phase is 0.6MPa, the pressure at the outlet of the solid phase is 0.2MPa, and the volume ratio of the materials at the outlet of the oil phase, the outlet of the solid phase and the outlet of the water phase is adjusted to 1: 5: 25, and the oil phase at the top is sent to the biochemical system for further processing. Degradation treatment, the...

Embodiment 3

[0057] The cleaning waste liquid on the surface of the cut silicon wafer is first subjected to natural sedimentation treatment. The large particle silicon powder obtained at the bottom and the sedimentation supernatant are sent to the ozone reaction tank, and are treated at 45°C and 1200-1500ppm concentration of ozone for 30 minutes, and then Send it to the oil-water-solid three-phase cyclone separator for separation treatment. In the separator, the flow rate of the feed is adjusted to 6min / s. The top is the oil phase outlet, the side is the solid phase outlet, and the bottom is the water phase outlet. The pressure at the outlet is 0.56MPa, the pressure at the outlet of the solid phase is 0.16MPa, and the volume ratio of the materials at the outlet of the oil phase, the outlet of the solid phase and the outlet of the water phase is adjusted to 1:4:22, and the oil phase at the top is sent to the biochemical system for further processing. Degradation treatment, the silicon powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com