Ship ballast water treatment system based on electro-catalysis and membrane distillation integrated device

A technology of ship ballast water and electrocatalytic membrane, applied in special compound water treatment, oxidized water/sewage treatment, water/sewage treatment, etc. Wetness and other problems, to achieve the effect of improving removal rate and wastewater reuse rate, water production rate improvement, strong oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

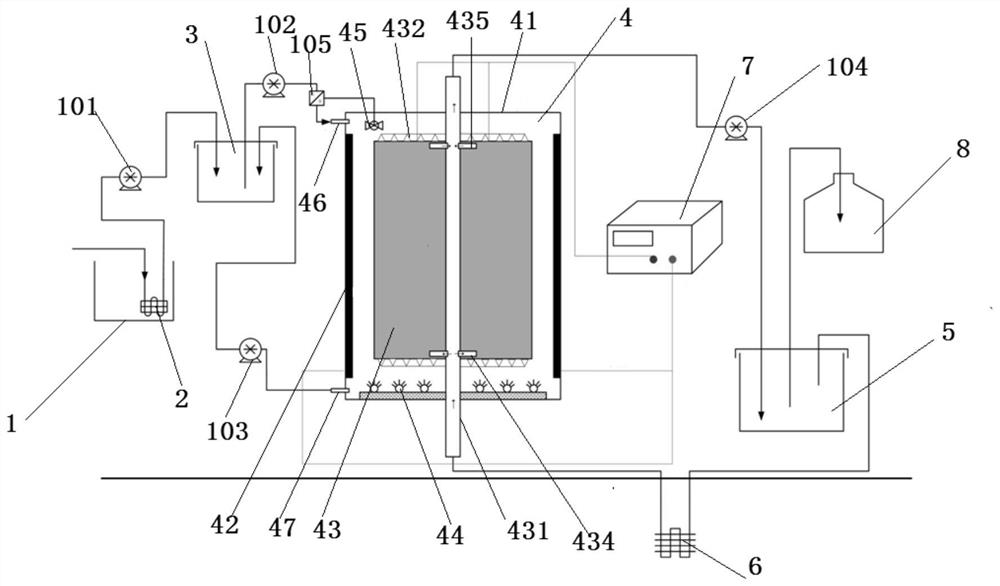

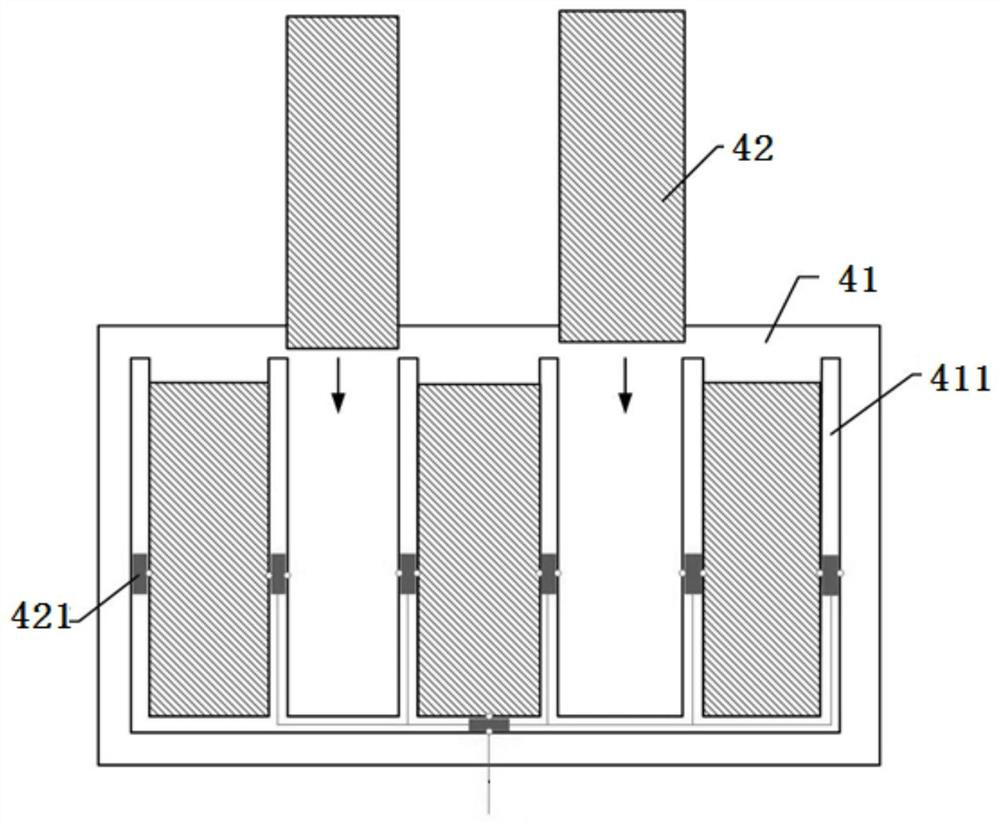

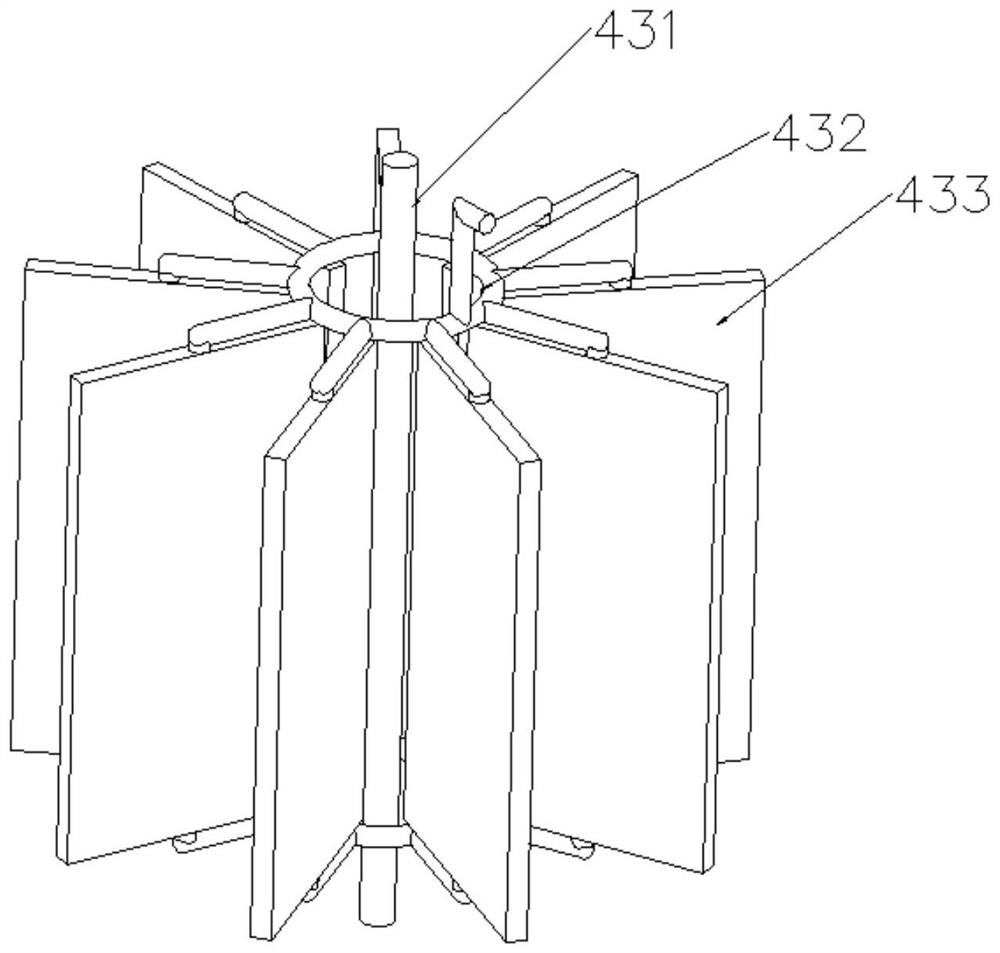

[0044] see Figure 1-5 As shown, the present invention discloses a ship ballast water treatment system based on an electrocatalytic membrane distillation integrated device, such as figure 1 As shown, it includes a ship engine cooling pool 1, a hot-side heating device 2, a hot-side water tank 3, an electrocatalytic membrane distillation reactor 4, a cold-side water tank 5, and a permeate cooling system 6 connected sequentially through pipelines;

[0045] It also includes a DC power supply 7 for powering the electrocatalytic membrane distillation reactor 4 and a clean water storage tank 8 connected to the cold side water tank 5;

[0046] The hot-side heating device 2, the hot-side water tank 3, and the electrocatalytic membrane distillation reactor 4 form a hot-side circulation system through the first sewage pump 101, the second sewage pump 102, and the hot-side circulation pump 103;

[0047] The hot-side heating device 2 heats up the ship's ballast water in the ship's engine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com