A kind of method for preparing aniline by hydrogenation of nitrobenzene

A technology for the preparation of nitrobenzene and hydrogen, which is applied to the preparation of amino compounds, chemical instruments and methods, and the preparation of organic compounds. It can solve the problems of complex catalyst preparation process, high reaction temperature and pressure, and difficult separation of catalysts. Aniline product selectivity, mild reaction conditions, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

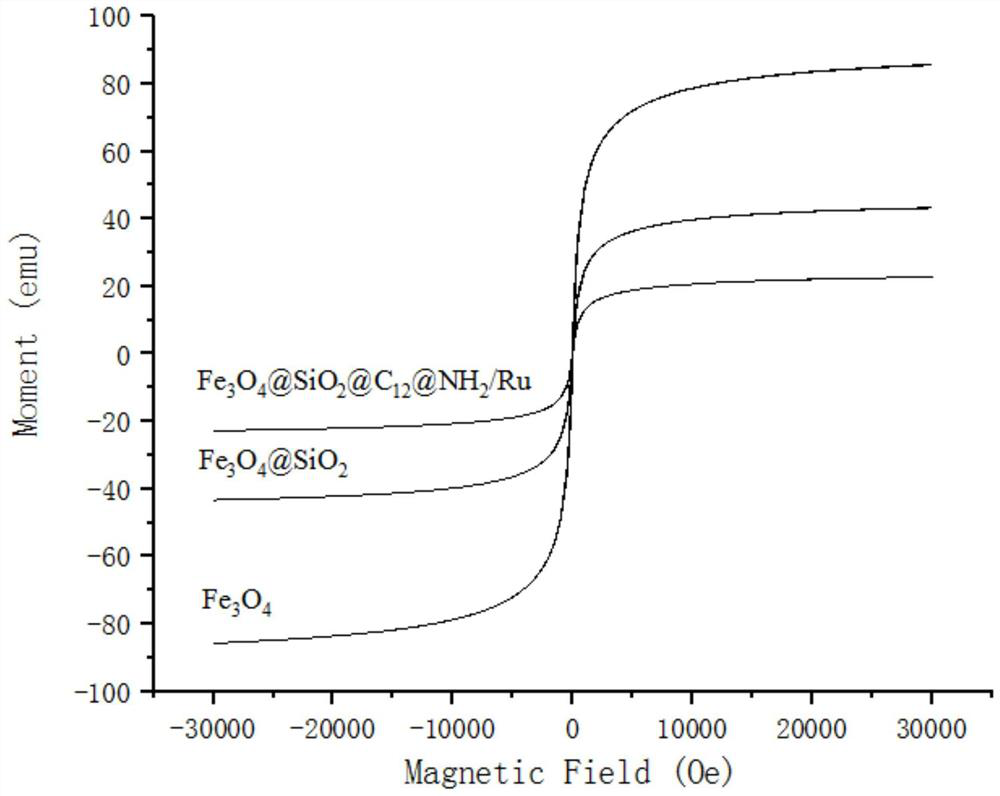

[0032] Embodiment 1 Catalyst Fe 3 o 4 @SiO 2 @C 12 @NH 2 / Preparation of Pd

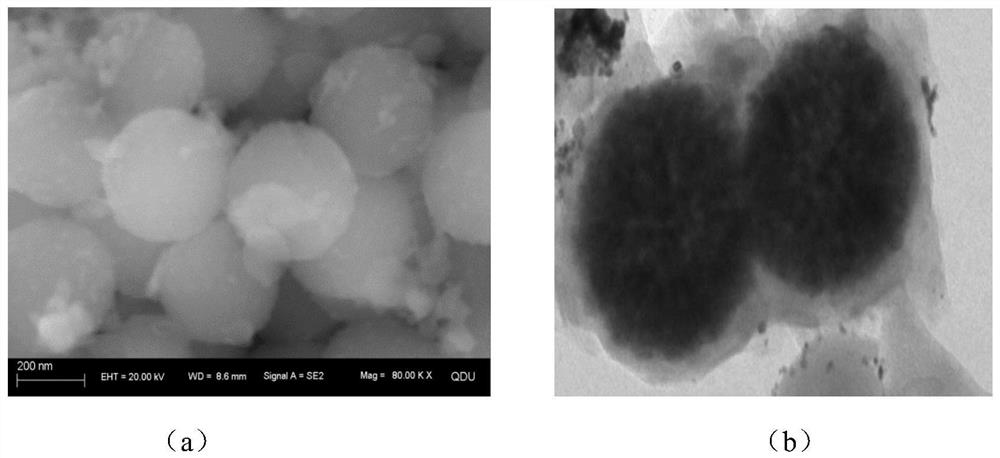

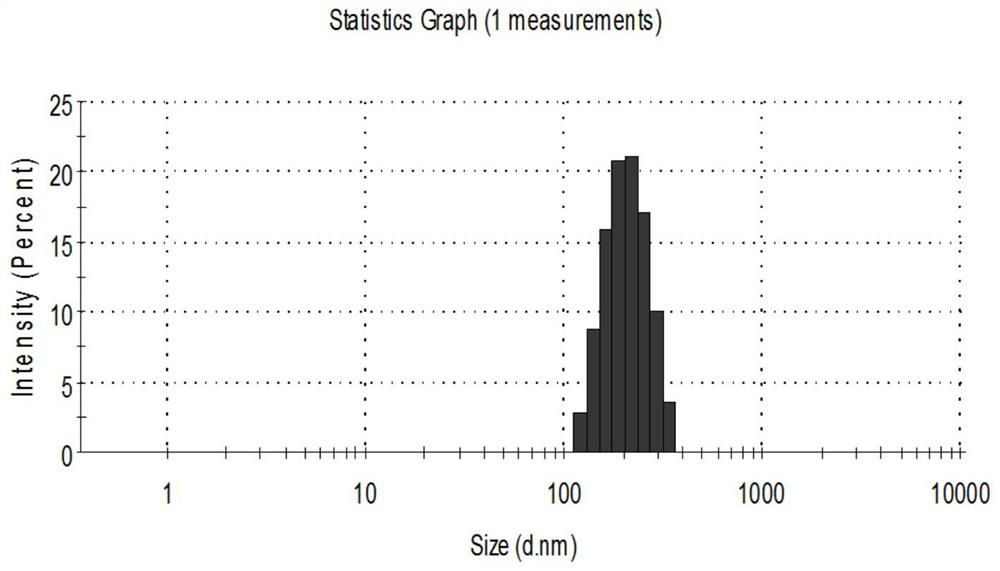

[0033] S 1 Preparation of Fe 3 o 4 Nanoparticles

[0034] Weigh 3.4g FeCl respectively 3 ·6H 2 O and 1.25 g FeCl 2 4H 2 O was added to a three-necked flask, then 100ml of water and 6ml of 25% ammonia water were added, stirred at 60°C for 40min, separated by an external magnetic field, washed several times with pure water, and vacuum-dried at 60°C for 4h;

[0035] S 2 Preparation of magnetic carrier Fe 3 o 4 @SiO 2

[0036] Weigh 1.4g Fe 3 o 4 Add to a 500ml three-neck flask, then add 5ml of 25% ammonia water, 70ml of water, 280ml of ethanol, dropwise add 1ml of TEOS (tetraethyl silicate), mechanically stir at room temperature for 8h, apply a magnetic field to separate, wash with water and ethanol three times , dried in vacuum at 50°C for 8 hours;

[0037] S 3 Preparation of Fe 3 o 4 @SiO 2 @C 12 @NH 2

[0038] Weigh 0.25g of prepared magnetic carrier Fe 3 o 4 @SiO 2 Add...

Embodiment 2

[0045] Embodiment 2 Nitrobenzene hydrogenation prepares aniline

[0046] Take by weighing 1g nitrobenzene and join in the stainless steel mechanical stirring kettle, add 20ml water then, take by weighing the magnetic amphiphilic catalyst Fe that 20mg embodiment 1 prepares 3 o 4 @SiO 2 @C 12 @NH 2 / Pd mixed evenly, replace the gas in the kettle with 1MPa hydrogen for 4 times, then flush into 1MPa hydrogen, and react with mechanical stirring at 40°C for 1h. After the reaction, separate the catalyst from the product under an external magnetic field, and extract with n-heptane After the product is produced, the upper product phase is collected and quantitatively analyzed by chromatography. The conversion rate of nitrobenzene is 99.6%, and the selectivity of aniline is 98.5%.

Embodiment 3

[0047] Embodiment 3 Catalyst recycling test

[0048] Take by weighing 1g nitrobenzene and join in the stainless steel mechanical stirring kettle, add 20ml water then, take by weighing the magnetic amphiphilic catalyst Fe that 20mg embodiment 1 prepares 3 o 4 @SiO 2 @C 12 @NH 2 / Pd mixed evenly, replace the gas in the kettle with 1MPa hydrogen for 4 times, then flush into 1MPa hydrogen, and react with mechanical stirring at 40°C for 1h. After the reaction, separate the catalyst from the product under an external magnetic field. , repeat the above experimental steps.

[0049] Catalyst Fe 3 o 4 @SiO 2 @C 12 @NH 2 / Pd was reused 7 times, the conversion rate of nitrobenzene reached 95.2%, the selectivity of aniline reached 98.5%, and the catalyst was reused 8 times, the conversion rate of nitrobenzene reached 85.2%, and the selectivity of aniline reached 95.7%. The above test results show that the catalyst Fe 3 o 4 @SiO 2 @C 12 @NH 2 / Pd reuse high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com