Anti-radiation paint and preparation method thereof

A technology for anti-radiation coatings and raw materials, applied in the field of coatings, can solve problems such as damage to physiological functions, inducing cancer, high price, etc., and achieve the effects of stabilizing adsorbed substances, improving surface strength, and good safety and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

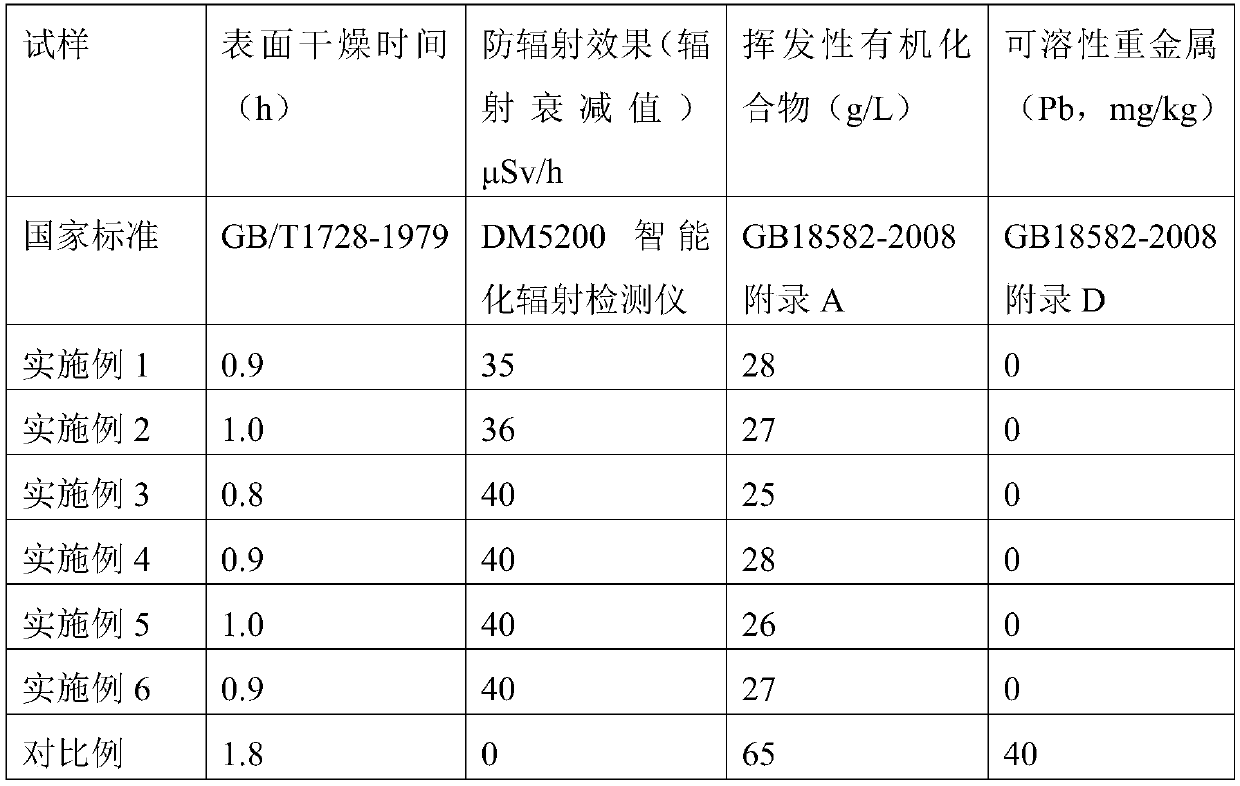

Examples

Embodiment 1

[0023] A preparation method of anti-radiation coating, comprising the following steps:

[0024] S1: Calculated in parts by weight, weigh 50 parts of barite, pulverize it, wash the broken barite with the sulfuric acid solution to obtain barium sulfate; dry the barium sulfate until the water content is lower than 12%, to obtain Barium sulfate powder; 10 parts of oyster shells are weighed, cleaned, dried, pulverized, and sieved to obtain oyster shell powder;

[0025] S2: Preparing the precursor gel: by weight, weigh 10 parts of lithium magnesium silicate, 50 parts of barium sulfate powder, 10 parts of oyster shell powder and 10 parts of activated carbon powder, add 50 parts of distilled water, and place in an ice bath environment Stir to form a mixed gel; add the NaOH solution dropwise to the mixed gel, continue to stir in an ice bath environment for 1 hour, then filter to obtain a precursor gel, and wash with distilled water;

[0026] S3: freeze-drying: put the above-mentioned ...

Embodiment 2

[0035] A preparation method of anti-radiation coating, comprising the following steps:

[0036] S1: Calculated in parts by weight, weigh 50 parts of barite, pulverize it, wash the broken barite with the sulfuric acid solution to obtain barium sulfate; dry the barium sulfate until the water content is lower than 12%, to obtain Barium sulfate powder; get 20 parts of oyster shells and wash it, dry, pulverize, and sieve to obtain oyster shell powder;

[0037] S2: Preparing the precursor gel: by weight, weigh 12 parts of lithium magnesium silicate, 55 parts of barium sulfate powder, 15 parts of oyster shell powder and 15 parts of activated carbon powder, add 60 parts of distilled water, and place in an ice bath environment Stir to form a mixed gel; add the NaOH solution dropwise to the mixed gel, continue stirring in an ice bath for 1.5 hours, then filter to obtain a precursor gel, and wash with distilled water;

[0038] S3: freeze-drying: put the above-mentioned precursor gel int...

Embodiment 3

[0046] A preparation method of anti-radiation coating, comprising the following steps:

[0047] S1: Calculated in parts by weight, weigh 50 parts of barite, pulverize it, wash the broken barite with the sulfuric acid solution to obtain barium sulfate; dry the barium sulfate until the water content is lower than 12%, to obtain Barium sulfate powder; get 20 parts and wash it, dry, pulverize and sieve to obtain oyster shell powder;

[0048] S2: Preparing the precursor gel: by weight, weigh 15 parts of lithium magnesium silicate, 60 parts of barium sulfate powder, 20 parts of oyster shell powder and 17 parts of activated carbon powder, add 60 parts of distilled water, and place in an ice bath environment Stir to form a mixed gel; add the NaOH solution dropwise to the mixed gel, continue to stir in an ice bath environment for 2 hours, then filter to obtain a precursor gel, and wash with distilled water;

[0049] S3: freeze-drying: put the above-mentioned precursor gel into the ref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap