A natural gas preparation system and an integrated skid-mounted natural gas preparation system

A technology for preparation system and natural gas, which is applied in the field of integrated skid-mounted natural gas preparation system and natural gas preparation system, which can solve problems such as waste of cost, large floor space, unfavorable movement, etc., to reduce production cost, high production efficiency, and realize small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

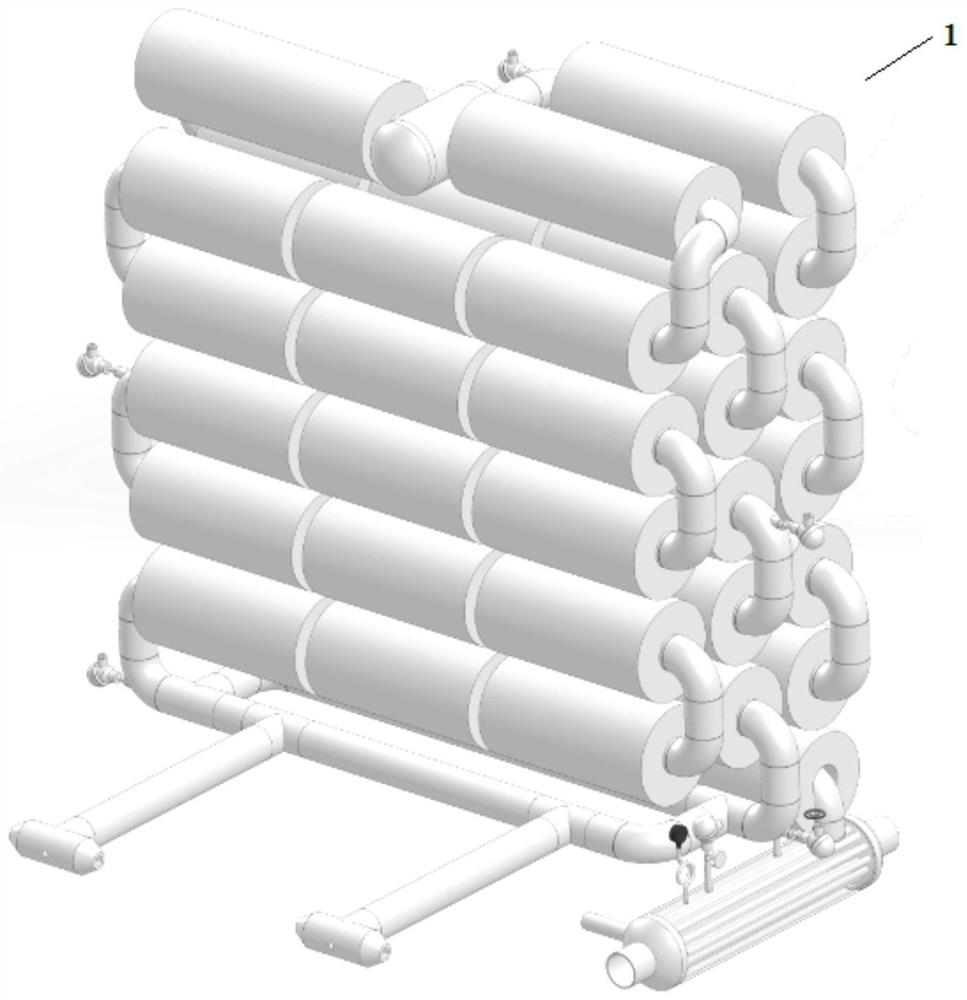

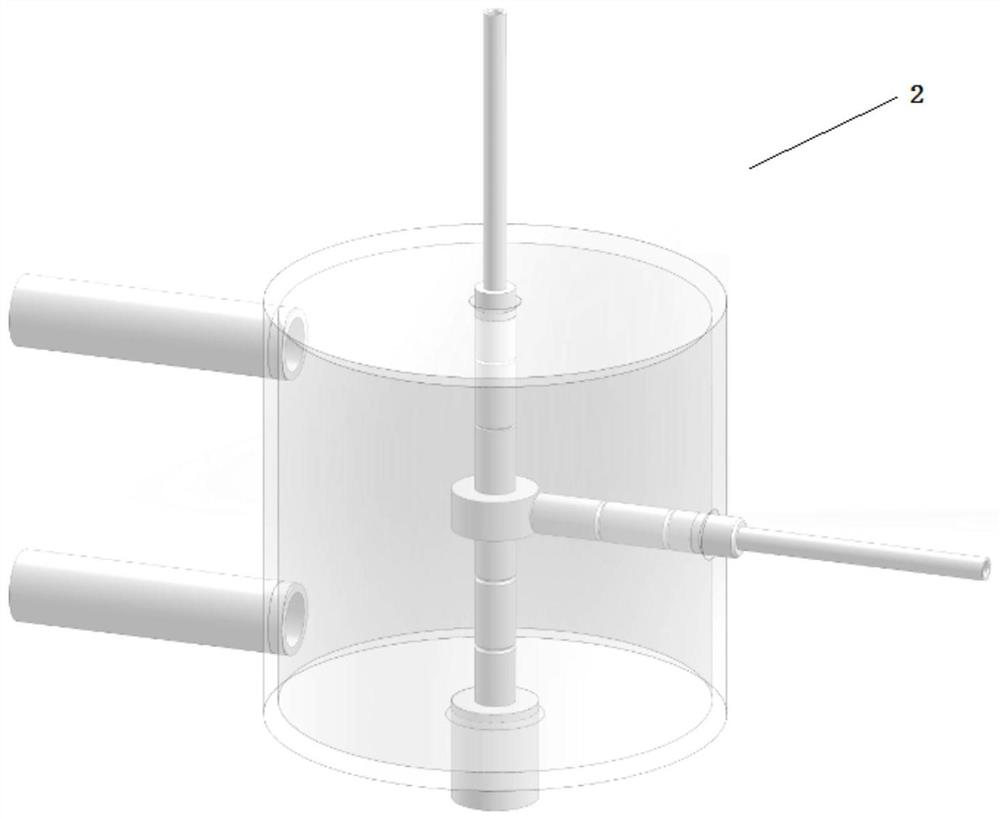

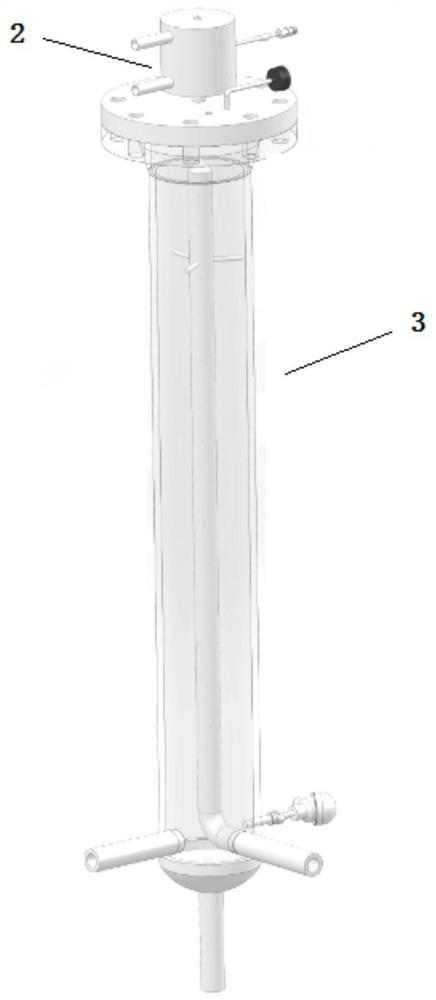

[0059] Figure 1 to Figure 7 Respectively show a schematic diagram of a subcritical water preparation device, a schematic diagram of an atomization device, a schematic diagram of a two-phase reaction vessel, a schematic diagram of a pipeline gasification reaction device, and a gas quenching filter device in a natural gas preparation system according to an embodiment of the present invention Schematic diagram, schematic diagram of gas-solid-liquid separation device, schematic diagram of water-vapor-slag separation device.

[0060] Such as Figure 1 to Figure 7 As shown, a natural gas preparation system includes: a subcritical water preparation device 1, an atomization device 2, and a two-phase reaction vessel 3, the water outlet of the subcritical water preparation device 1 communicates with the water inlet of the two-phase reaction vessel 3, and the mist The atomization port of the atomization device 2 communicates with the two-phase reaction vessel 3, and the subcritical wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com