Plastic drainage board externally wound with heating wires and consolidation drainage construction method of plastic drainage board

A technology of plastic drainage board and construction method, which is applied in the direction of basic structure engineering, soil protection, construction, etc., can solve the problems of inapplicability, complicated operation, etc., and achieve the effect of convenient connection, simple construction and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

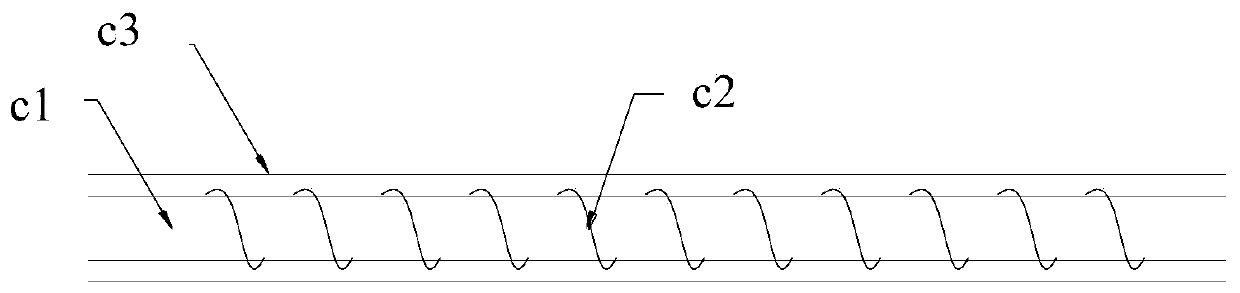

[0045] The utility model relates to a plastic drainage board with a heating wire wrapped around it, comprising a plastic drainage board and a heating wire, and the heating wires are arranged on both sides of the plastic drainage board. The heating wire includes a glass fiber bundle c1, a resistance wire c2 and an insulating waterproof layer c3, the resistance wire c2 is spirally wound on the glass fiber bundle c1, and the outer layer of the resistance wire c2 is covered with an insulating waterproof layer c3.

[0046] Further, the insulating waterproof layer of the heating wire is made of silica gel.

[0047] Further, the insulation resistance of the insulating waterproof layer of the heating wire is greater than 500MΩ.

[0048] Furthermore, the heating wire has heat resistance and can be used for a long time at 150° C. without any change in performance.

[0049] Further, the outer diameter of the heating wire is 2-5mm, and the tensile strength is greater than 1kg.

[0050] ...

Embodiment 2

[0052] The concrete drainage construction method of the plastic drainage board surrounding the heating wire is as follows:

[0053] (1) The site is leveled, and the medium-coarse sand cushion m is laid, and its permeability coefficient is required to be greater than 10 -3 cm / s;

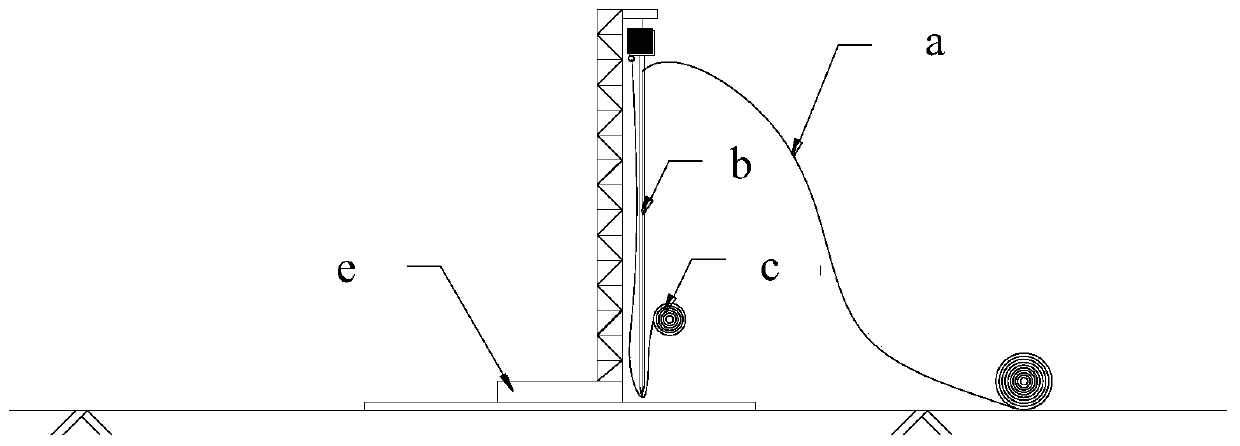

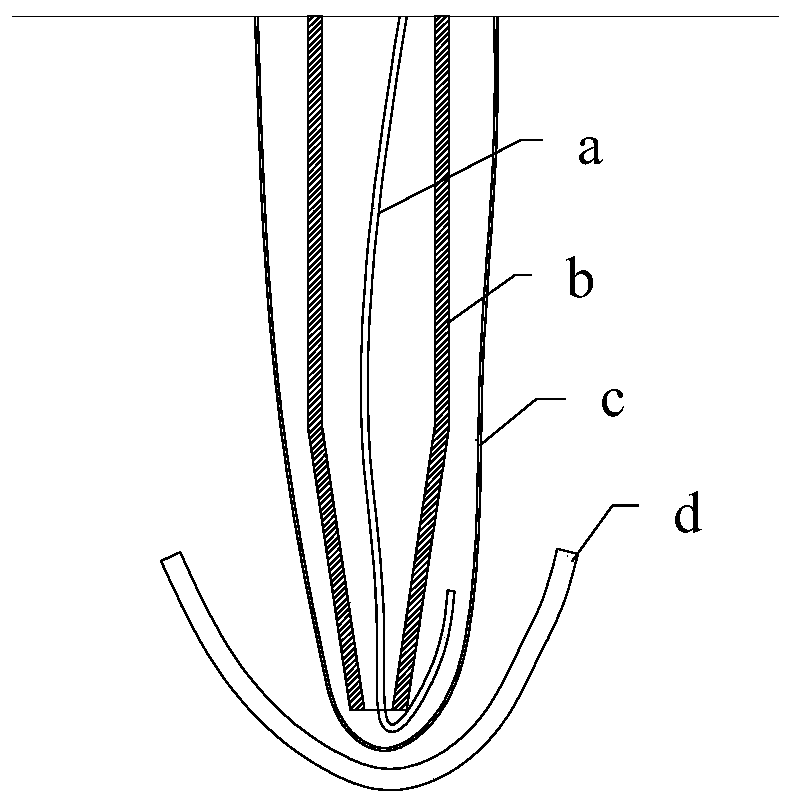

[0054] (2) Thread the plastic drainage plate a into the casing b first, lead out and bend it by 0.5m to prevent the plastic drainage plate from being brought back when it is pulled up;

[0055](3) Hang one end of the heating wire c on the top of the casing b, then hang freely along the casing, and go around the tube shoe of the casing. In order to protect the plastic drain board a and the heating wire c from being damaged during the insertion process, add a foam board d to the end of the tube shoe of the sleeve b;

[0056] (4) Insert the sleeve b to the specified depth at a certain rate through the inserting plate machine e. During the insertion of the sleeve, keep the heating wire on the other side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com