Device and method for fast construction of anti-seepage wall

A technology of construction device and construction method, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of high construction difficulty, in-hole accident, low efficiency, etc., to improve construction quality, reduce construction difficulty, device structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

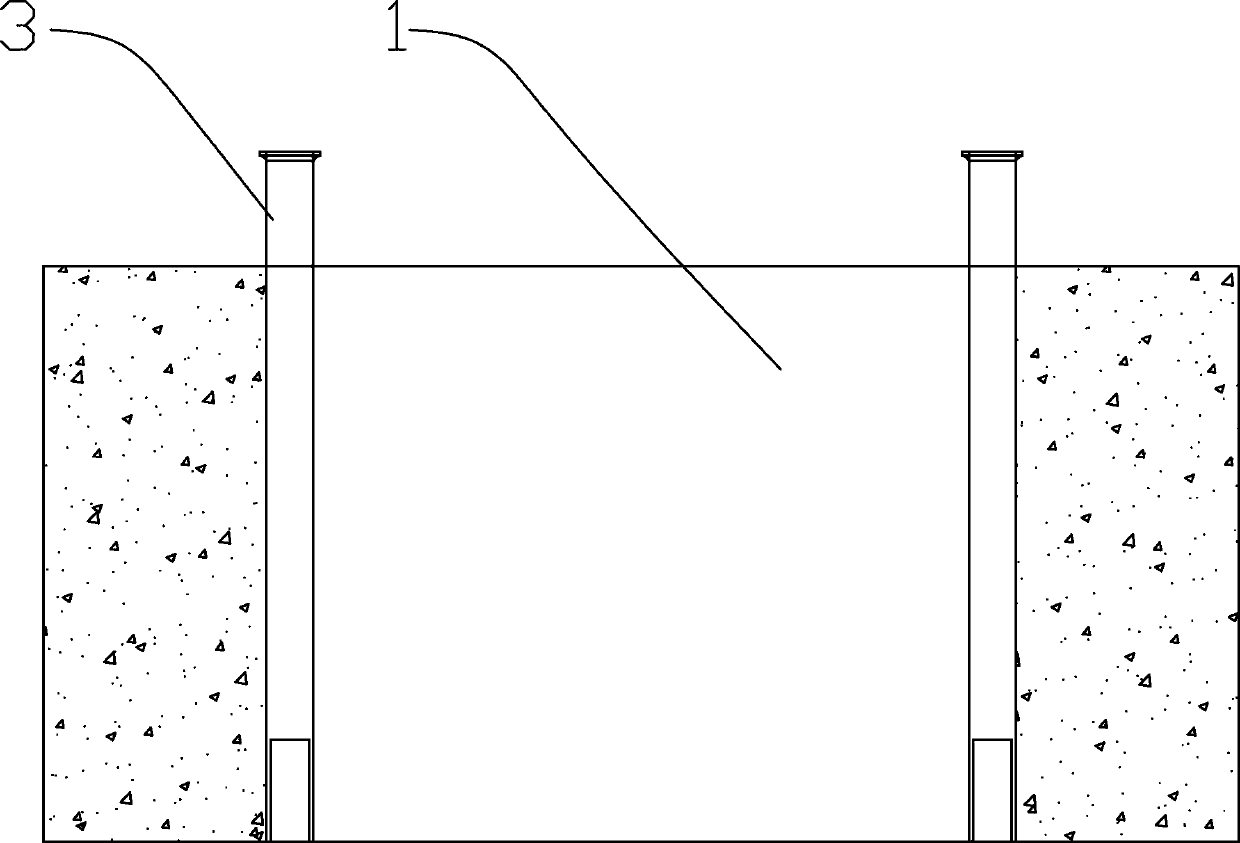

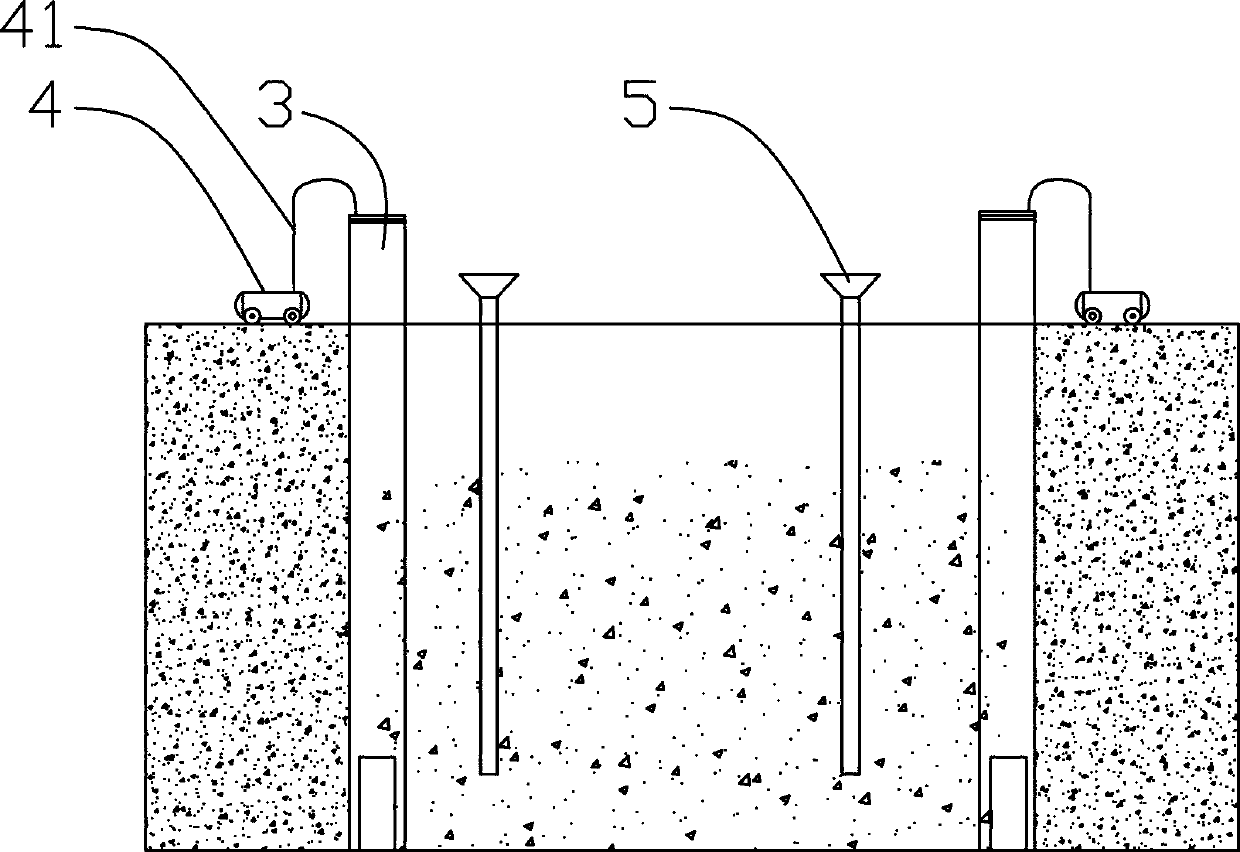

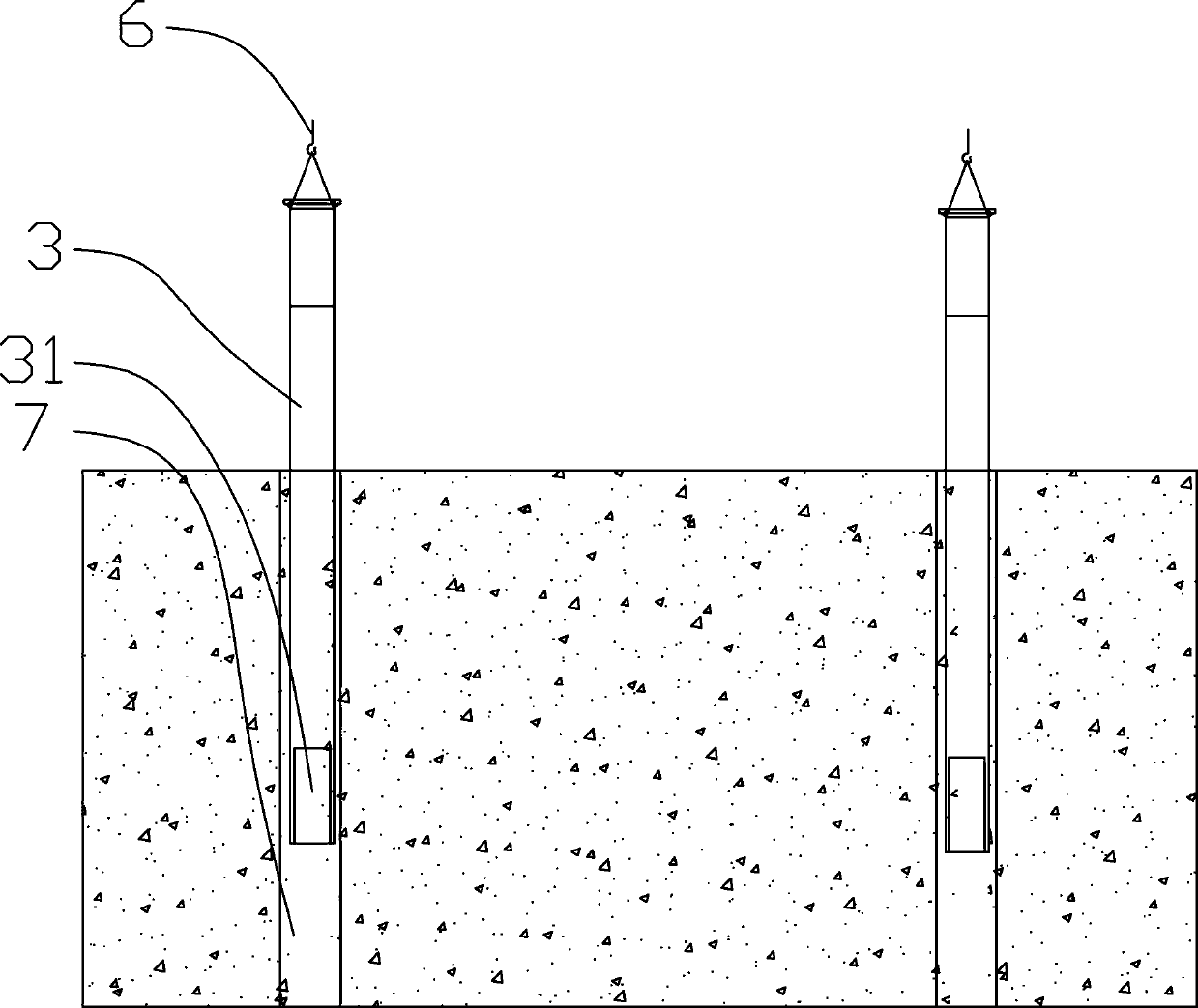

[0039] Such as figure 1 , 6 Among them, a fast construction device for cut-off walls, which includes a joint pipe 3, the joint pipe 3 is provided with a flexible joint pipe body 310, the bottom of the joint pipe body 310 is fixedly connected with the bottom plate 307, and the top of the joint pipe body 310 is connected to the top cover 301 fixed connection;

[0040] The joint pipe body 310 , the bottom plate 307 and the top cover 301 form a sealed cavity, and a joint is provided on the top cover 301 for connecting with the medium pipe 41 to fill and discharge pressure medium into the joint pipe 3 . With this structure, before pouring the joint hole 7, the joint pipe 3 can be filled with a pressure medium, such as compressed air, water or a combination of air and water, so that the diameter of the joint pipe 3 can be increased and the shape can be maintained during the pouring process. constant. When pulling out the joint pipe 3, the pressure medium can be discharged to redu...

Embodiment 2

[0051] A construction method using the above-mentioned rapid construction device for cut-off walls, comprising the following steps:

[0052] S1. A slot is constructed on the basis of the cut-off wall, and two joint pipes 3 are placed at both ends of the slot;

[0053] S2. Inject a pressure medium into the joint pipe 3 to expand the diameter of the joint pipe body 310 of the joint pipe 3 to a predetermined diameter; in this example, the solution of injecting water at the bottom and injecting compressed air at the top is preferred, while ensuring sufficient pressure, it also makes the Joint pipe 3 has enough self-weight, can break open mud and sink to the bottom of slotted hole. At the same time, it can also reduce its own weight and reduce the difficulty of extubation.

[0054] S3. Lower the pouring pipe 5 into the slot, and pour the concrete wall in the slot;

[0055] S4. After the initial setting of the concrete wall, the pressure medium in the joint pipe 3 is discharged. P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com