Electric window opening machine capable of being operating manually

A manual operation and window opening machine technology, applied in the direction of power control mechanism, wing leaf control mechanism, door/window accessories, etc., can solve the problem of power failure and inoperability, and achieve labor-saving operation, cost reduction, and simple manual operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

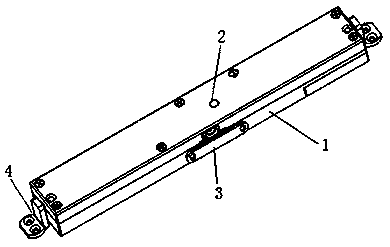

Image

Examples

Embodiment approach

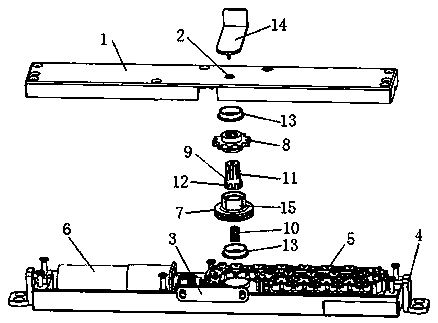

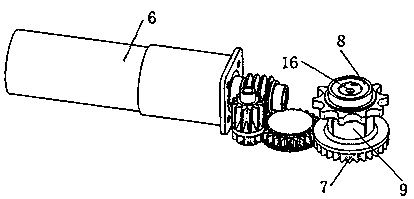

[0036] Wherein, the elastic body may be a spring 10 , an elastic rod or other elastic structures. As an embodiment of the present invention, the elastic body adopts the spring 10 .

[0037] The transmission shaft 9 is concavely provided with a lower pressure groove 16 on the end surface provided with the second key teeth 11, and a pressure port 2 penetrating through the housing 1 is opened on the housing 1 corresponding to the lower pressure groove 16, through which the housing 1 Use the handle 14 to extend the pressure port 2 on the top into the housing 1 to carry out a pressure test on the lower pressure groove 16, which can control the separation of the transmission shaft 9 and the sprocket 8, cut off the power input, and realize manual operation.

[0038] During installation, the shaft sleeve 13 is installed at the installation place of the transmission gear 7 in the housing 1, the spring 10 is placed in the center of the shaft sleeve 13 in the housing 1, and the spring 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com