Discharge valve

A discharge valve and valve body technology, which is applied to slide valves, valve details, valve devices, etc., can solve problems such as unsuitable nuclear medium discharge, and achieve the effect of improving sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

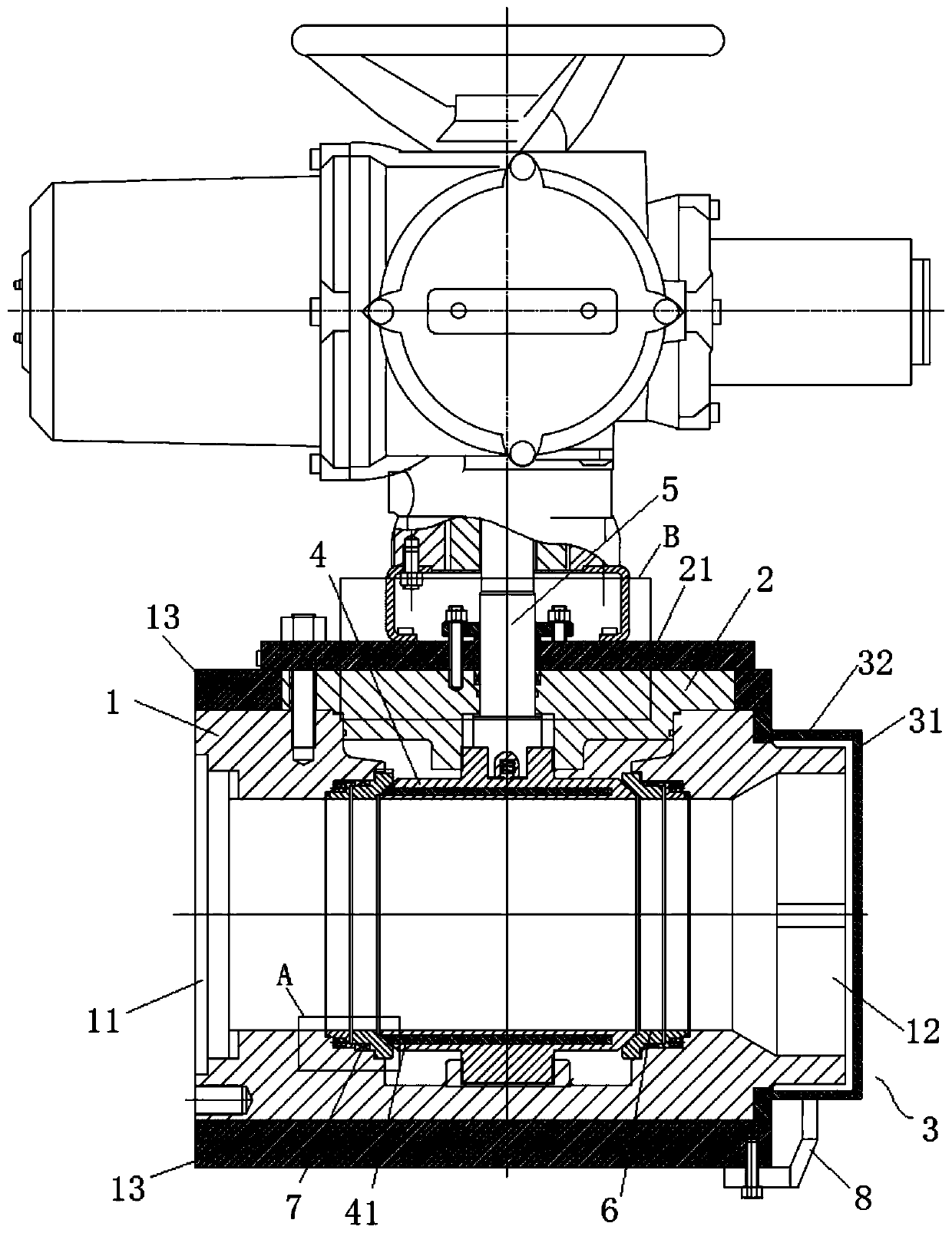

[0049] Such as Figure 1-4 As shown, the present embodiment provides a discharge valve, which includes:

[0050] A valve body 1 with a valve cavity inside, the valve body 1 has an inlet port 11 and an outlet port 12;

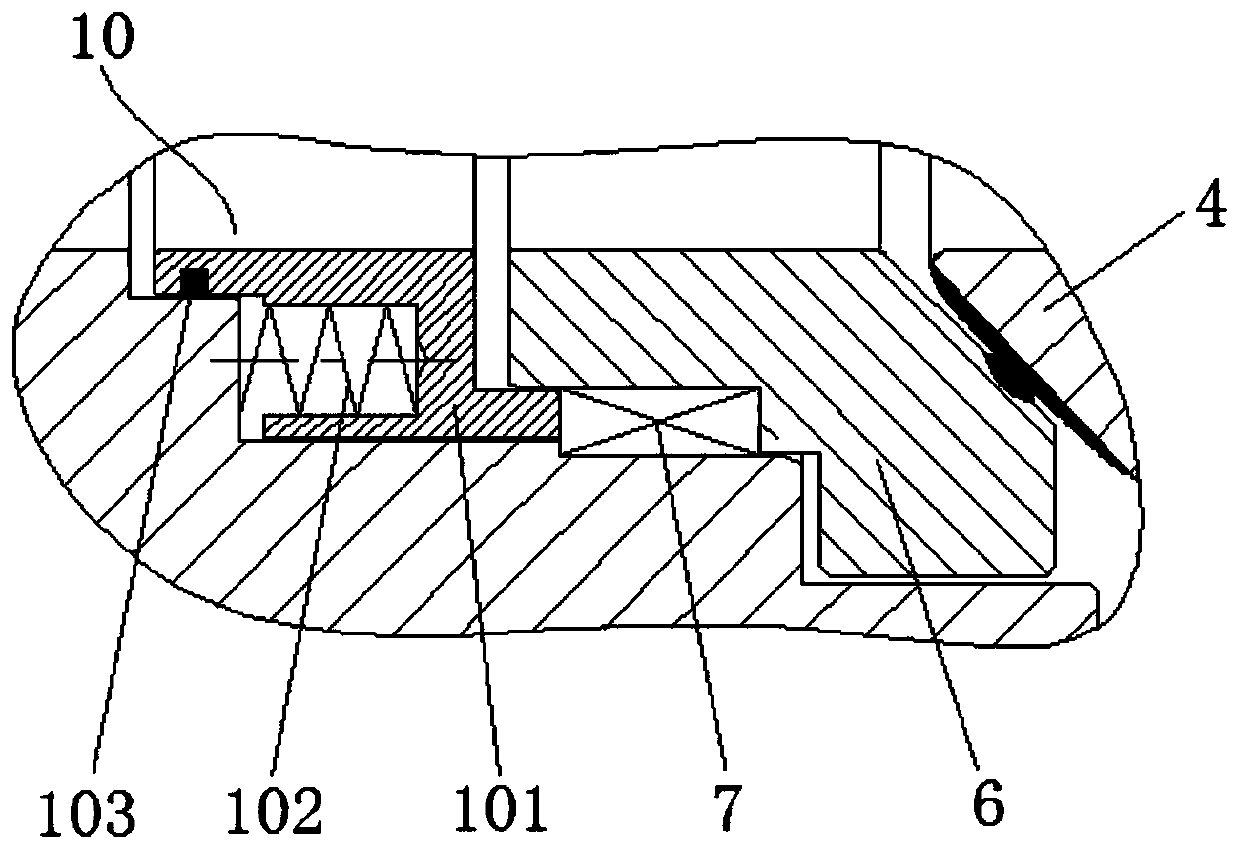

[0051] The ball 4 as the opening and closing part is assembled in the valve cavity and is suitable for controlling the on-off of the discharge valve;

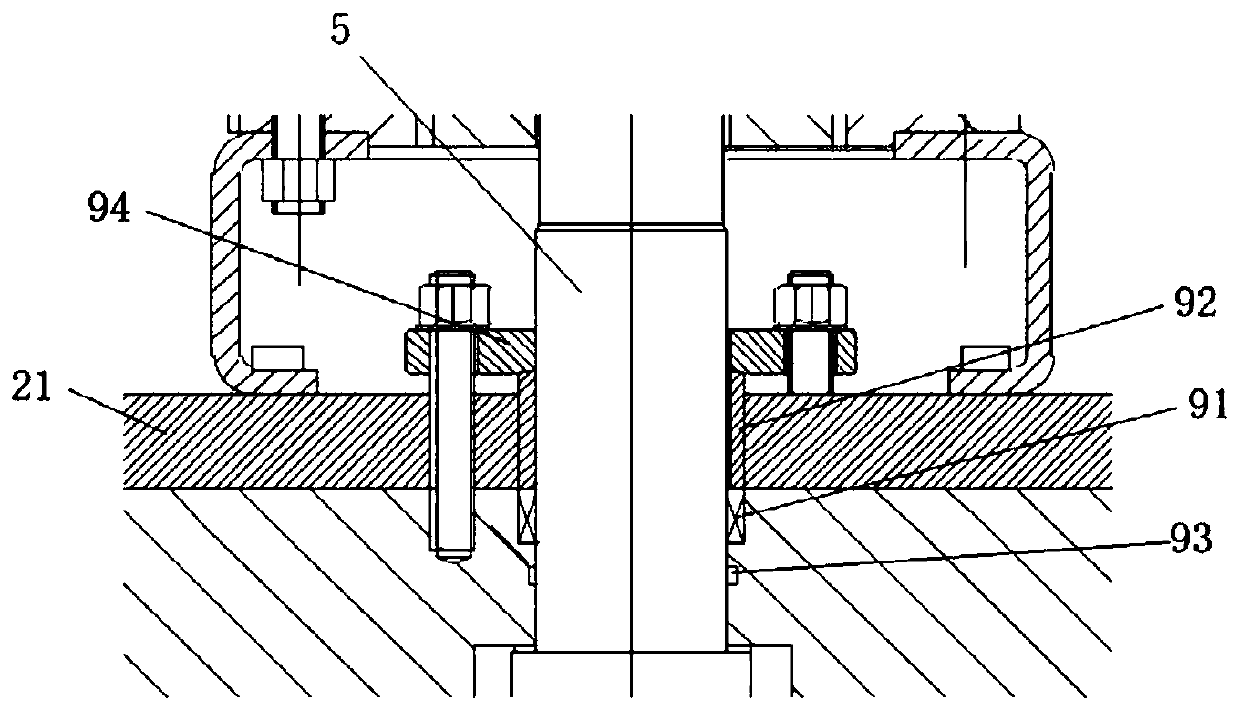

[0052]The sphere 4 has a through hole; when the through hole communicates with the valve cavity, the valve body channel is opened; the valve body channel is respectively communicated with the inlet port and the outlet port; the discharge valve also includes, a valve stem 5, which is connected to the ball 4 and drives the ball 4 to open or close the passage of the valve body;

[0053] The radiation shielding cover 3 includes a body 31; a side plate 32, which surrounds the body 31, and one end of the side plate 32 is connected to the body 31 or is integrally made with the body (31), and faces away from the body (...

Embodiment 2

[0070] This embodiment provides a discharge valve. Compared with the discharge valve provided in Embodiment 1, the difference is that the opening and closing part is a gate plate, which is assembled in the valve cavity and is suitable for controlling the opening and closing of the discharge valve. broken.

[0071] Further, a third shielding layer can be embedded in the shutter, and the second shielding layer can be selected as a graphene composite shielding material or a lead-based nuclear shielding material, which can realize that when the discharge valve is closed, the radiation shielding cover Cooperate to form a shielding and sealing cavity at the gate and the outlet of the valve body, which not only ensures that the radioactive liquid will not leak, but also ensures that the radiation will not pass through the above-mentioned shielding and sealing cavity, thereby preventing pollution of the external environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com