A stainless steel corrugated hose for connecting gas appliances

A technology for gas appliances and corrugated hoses, which is applied to hose connection devices, pipes/pipe joints/fittings, manufacturing tools, etc., can solve problems such as increasing on-site installation safety hazards, loosening of Green joint interfaces, and increasing installation costs. The effect of overcoming sealing inspection, solving technical difficulties and reducing overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

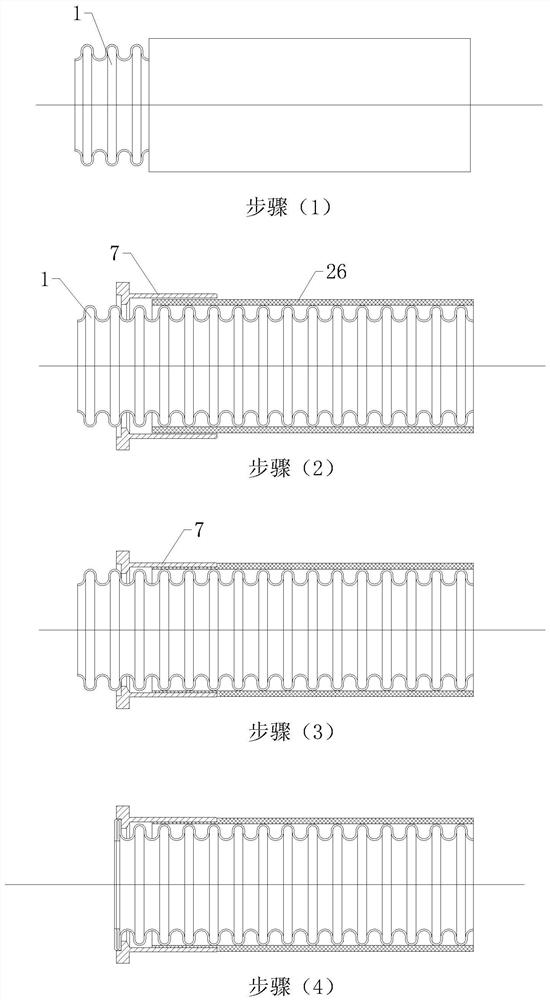

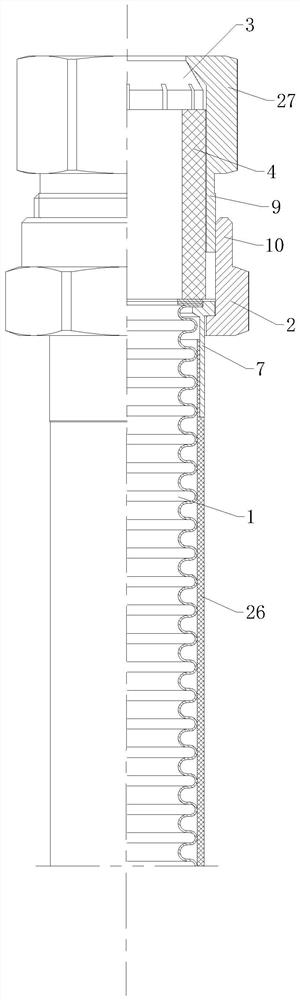

[0039] refer to Figure 1 to Figure 5 A stainless steel corrugated pipe with an improved structure shown includes a stainless steel corrugated pipe 1, a plug-in interface and a threaded interface. The plug-in interface and the threaded interface are respectively arranged at both ends of the stainless steel bellows 1. A rotating nut 2, a reinforced snap ring 3 and a plug-in sealing ring 4, the threaded interface includes a second rotating nut 5 and a flat washer sealing ring 6, and both ends of the stainless steel bellows 1 are fastened with connections for the first rotating nut 2 and The shrinking flange 7 that is socketed by the second rotating nut 5, the outside of the stainless steel bellows 1 is wrapped with a coating layer 26 made of soft material, the fixing nut 27 is detachably connected with the first rotating nut 2, and the plug-in sealing ring 4 It is located inside the fixed nut 27 and its two ends are pressed against the fixed nut 27 and the corresponding stainles...

specific Embodiment 2

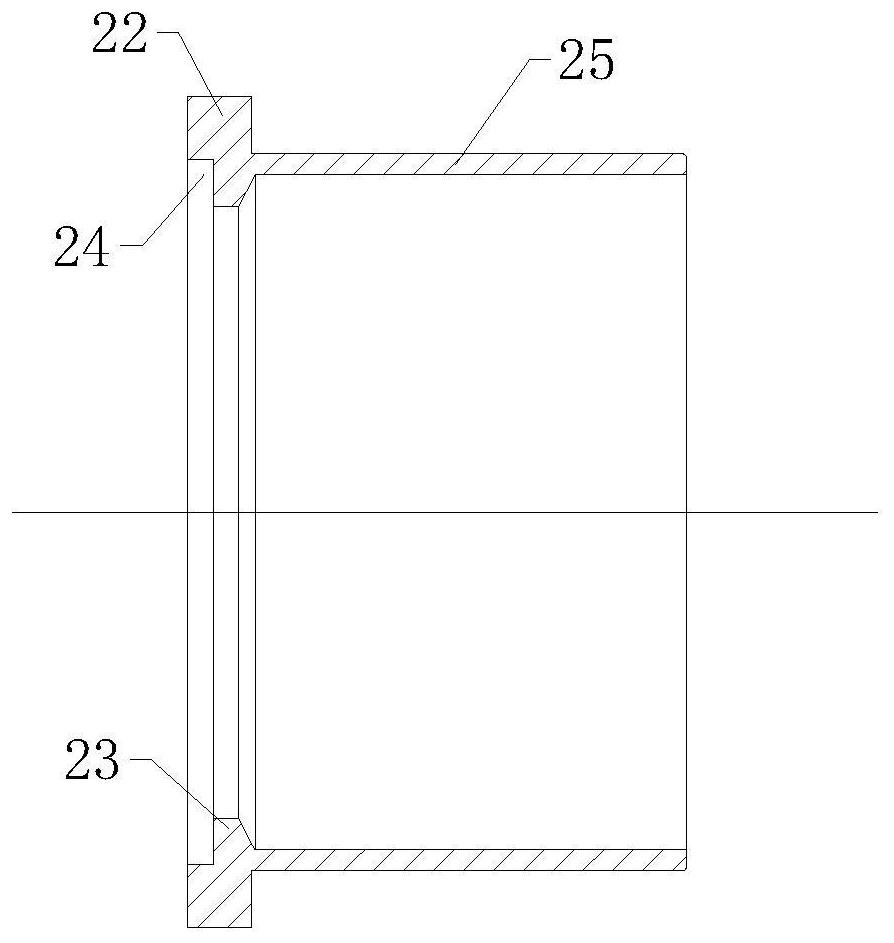

[0054] The difference from the first embodiment is that the connection between the upper connecting part 10 and the lower connecting part can be not only through threaded connection, but also through such as Figure 5 to Figure 8 The scheme shown is realized, specifically, the outer wall of the upper connecting part 10 is symmetrically provided with two arc-shaped chute 14 inclined upward along the cylindrical wall, and the upper and lower ends of each arc-shaped chute 14 are respectively provided with vertically downward The notch 15 and the sinker 16 of the notch, the bottom of the notch 15 communicate with the lower side of the lower connecting part 9, and the cylindrical wall of the lower connecting part 9 is embedded with two cylindrical pins 17 that slide with the arc-shaped chute 14, and the fixing nut 27 and the connection of the lower connecting part 9 are provided with an upwardly extending annular accommodation groove 18, the depth of the annular accommodation groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com