Energy-saving design method of intelligent energy-saving straight tube plant lamp

A design method and plant lamp technology, applied in the field of plant lamps, can solve the problems of low power, insufficient light intensity, low luminous efficiency, etc., and achieve the effect of increasing the heat dissipation surface area, meeting the heat dissipation requirements, and improving the light intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

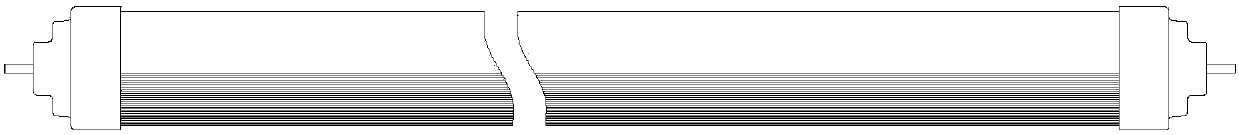

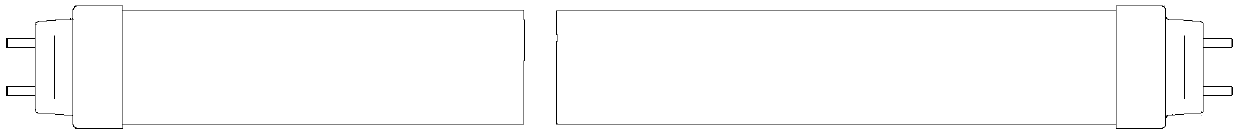

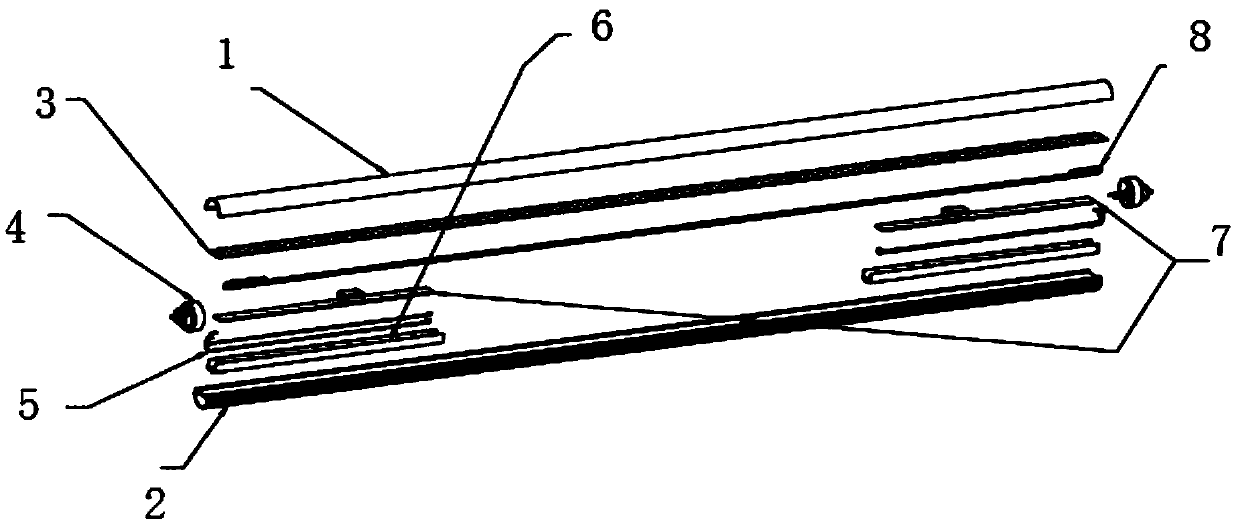

[0012] The lamp shell is composed of aluminum profile, transparent PC lampshade, G13 lamp holder (two) ( figure 1 Appearance hints, figure 2 For decomposition, the aluminum profile has grooves to increase the heat dissipation area to provide a structural basis for heat dissipation for the lamp tube to increase power. The widening of the lamp panel adopts the arrangement of two rows of lamp beads to increase the number of lamp beads. The power supply adopts the scheme of two single-ended power supplies to increase the overall power of the lamp tube (up to 42W). The two power supplies are wrapped with insulating materials at both ends of the lamp tube to prevent leakage, and the overall center of gravity is centered. The two power supplies are connected with a sheathed cable to achieve the purpose of single-ended power supply, thereby simplifying the process of on-site wiring construction in the plant factory and saving costs. In addition, through the improvement of power sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com