Continuous material hardness detecting device with deviation-preventing structure

A detection device and anti-deviation technology, which is applied in the direction of testing material hardness, measuring device, and analyzing materials, etc., can solve the problems of deviation of measurement results, pressing-in surface is not a horizontal plane, and poor effect, so as to reduce shaking and offset effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

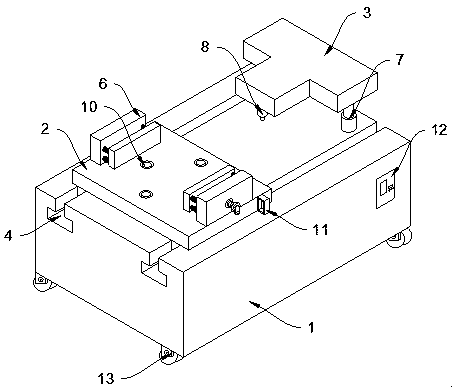

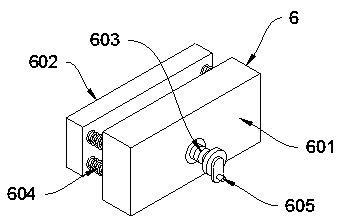

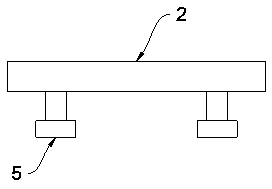

[0023] Example: such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention has a continuous material hardness testing device with an anti-deviation structure, including a workbench 1, a placement plate 2 and a T-shaped moving plate 3, and both sides of the top of the workbench 1 are provided with an inverted T. Shaped chute 4, the placement plate 2 is placed on the top of the two chute 4, and the placement plate 2 is slidably connected with the chute 4 through the slider 5 provided at the four corners of the bottom end and matched with the chute 4 , both sides of the top of the placing plate 2 are fixedly provided with a squeezing mechanism 6 for squeezing the material, the moving plate 3 is located between the two chutes 4 on one side of the top of the workbench 1, and the two sides of the bottom of the moving plate 3 are Both are fixedly equipped with an electric push rod 7, and the middle part of the other side of the bottom end of the moving p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com