Magnetic shielding sheet for non-contact charging and application thereof

A magnetic shielding, non-contact technology, applied in the direction of preventing/reducing unwanted electric/magnetic influence, transformer/inductor cooling, etc., can solve the problem of not considering heat conduction, increase the die-cutting and bonding of amorphous tape composites Process complexity and other issues to achieve efficient heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

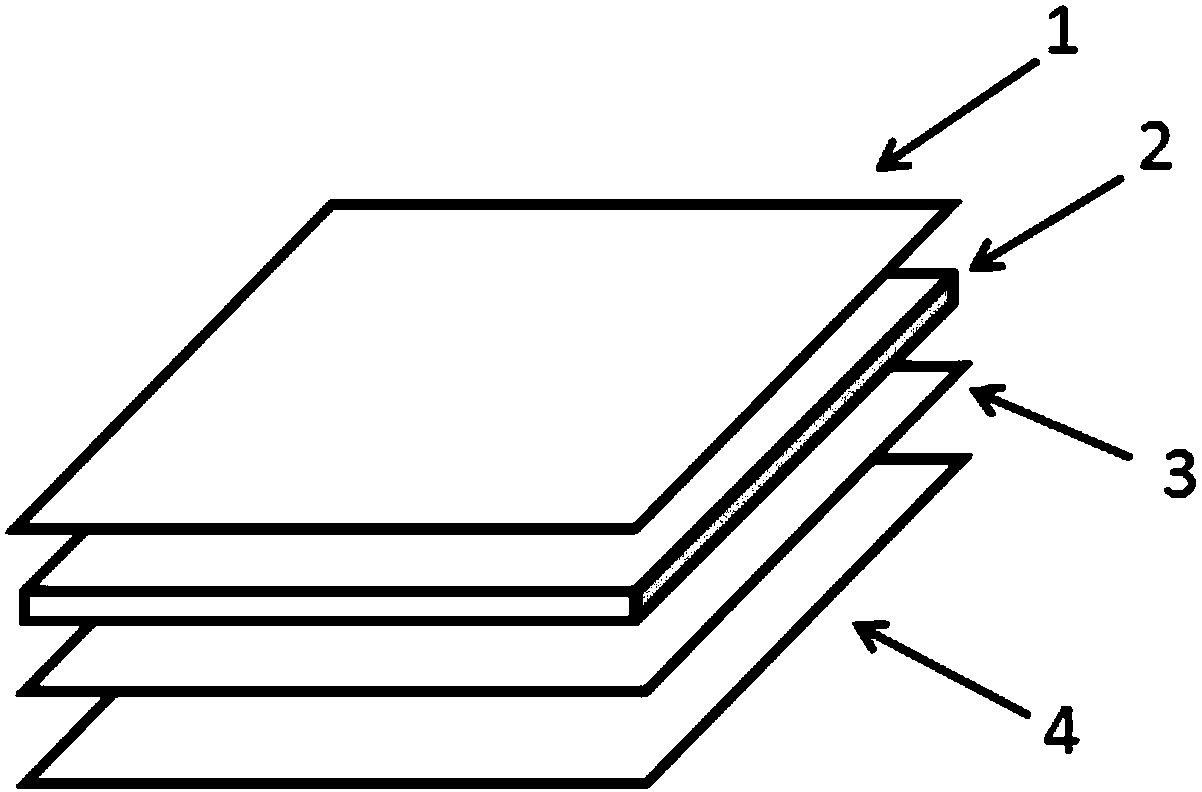

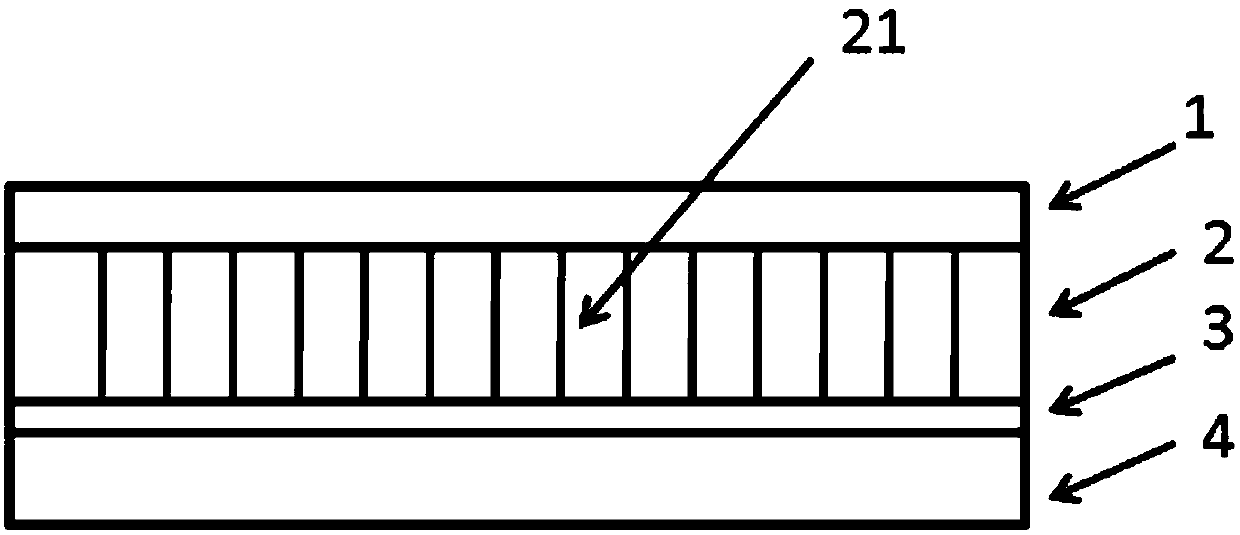

[0028] The magnetic shielding sheet for non-contact charging of embodiment 1, such as figure 1 and figure 2 As shown, it includes: a magnetic alloy layer 2 with a thickness of 10-30 μm, the magnetic alloy layer 2 is formed by splicing a plurality of magnetic alloy sheets 21 laterally, and the two surfaces of the magnetic alloy layer 2 are respectively provided with heat dissipation layers 1 and the adhesive layer 3 , the composition of the heat dissipation layer 1 includes carbon nanotubes, and the surface of the adhesive layer 3 is provided with a release film 4 .

[0029] In Embodiment 1, an insulating layer (not shown in the figure) may also be provided between the plurality of magnetic alloy sheets 21 to further reduce the eddy current loss on the surface of the magnetic alloy layer 2 .

[0030] In Example 1, the magnetic alloy layer is made of iron-based amorphous alloy, specifically, the iron-based amorphous alloy is Fe-Si-B iron-based amorphous alloy, and its atomic p...

Embodiment 2

[0033] The magnetic shielding sheet for non-contact charging in Example 2 differs from Example 1 in that in Example 2, the composition of the heat dissipation layer 1 includes carbon nanotubes and graphene, and in the heat dissipation layer 1, solidified In terms of the mass of the final ink, the mass proportion of carbon nanotubes is 9%, and that of graphene is 6%.

Embodiment 3

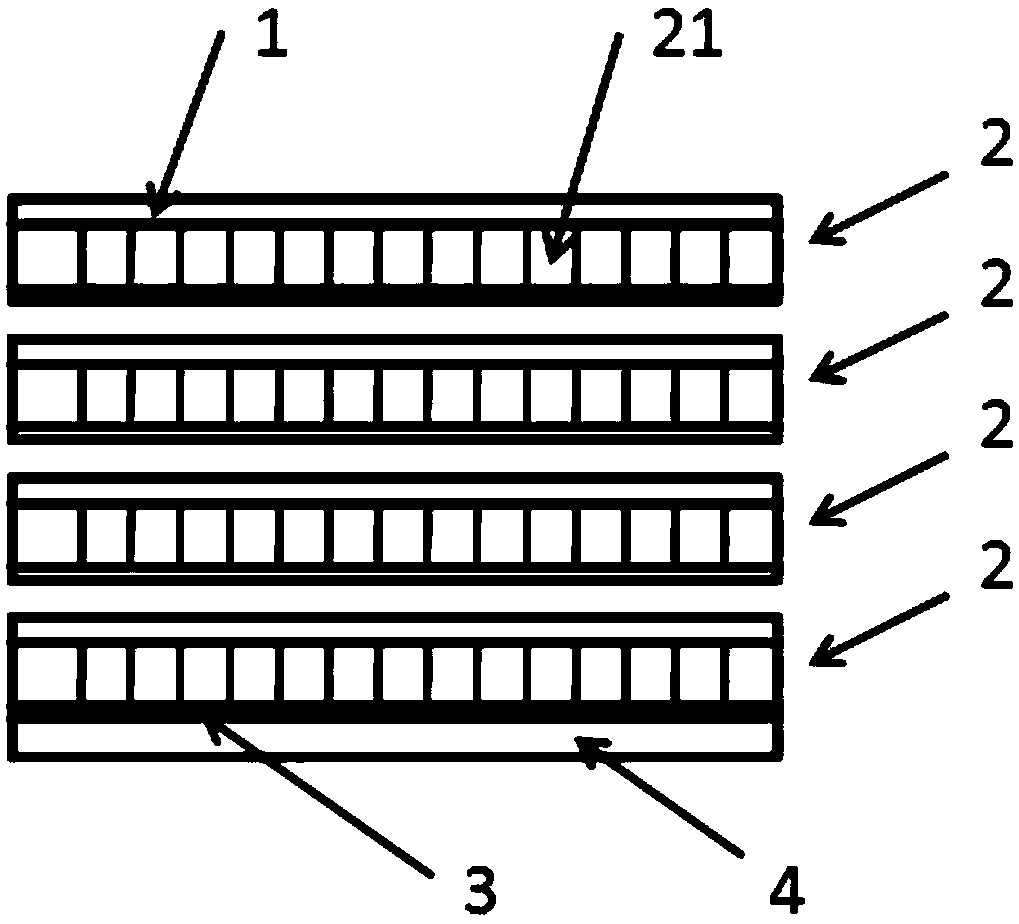

[0034] The magnetic shielding sheet for non-contact charging of embodiment 3, such as image 3 As shown, it includes: four layers of magnetic alloy layers 2 stacked vertically with a thickness of 10-30 μm, each layer of magnetic alloy layer 2 is formed by splicing a plurality of magnetic alloy sheets 21 horizontally, and the two surfaces of each layer of magnetic alloy layer 2 Both are provided with a heat dissipation layer 1 and an adhesive layer 3, and the composition of the heat dissipation layer 1 includes carbon nanotubes.

[0035] The magnetic alloy layer in embodiment 3 is made of iron-based amorphous alloy, and its composition is the same as that in embodiment 1.

[0036] The preparation process of the magnetic shielding sheet for non-contact charging in Example 3 is as follows: the four-layer magnetic alloy layer 2 is subjected to a non-magnetic field heat treatment for 30 minutes to 2 hours in the temperature range of 300 ° C to 600 ° C, in order to obtain a higher ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com