How solar panels are made

A technology of solar panels and manufacturing methods, applied in the direction of chemical instruments and methods, circuits, photovoltaic power stations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

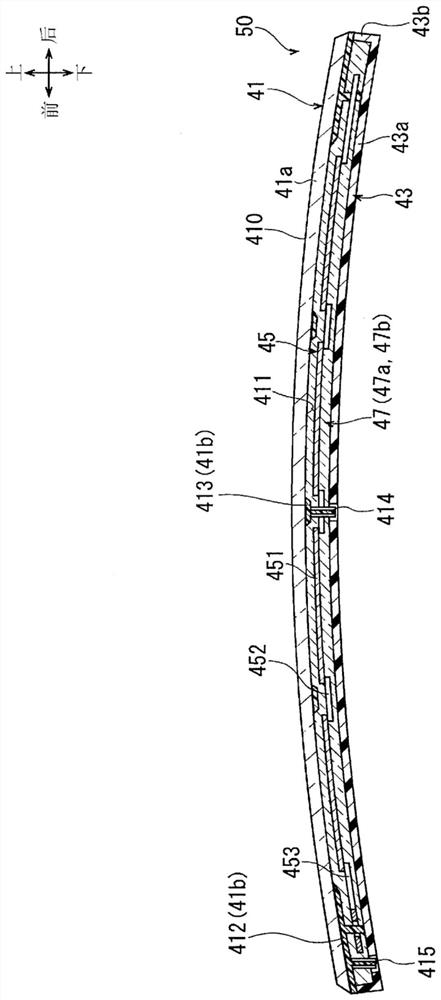

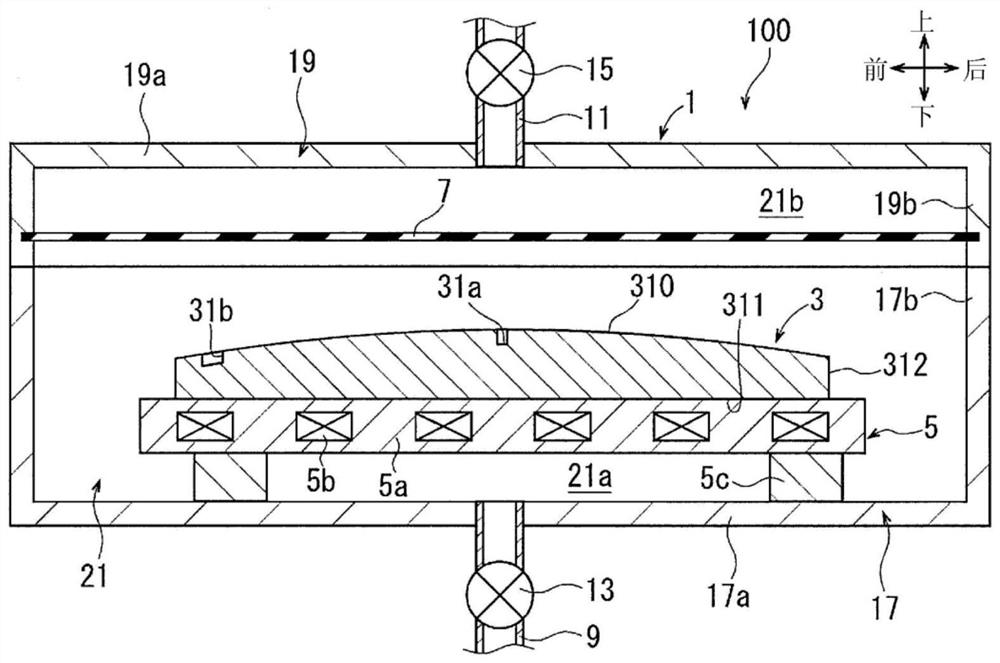

[0021] like figure 1 As shown, the solar cell panel 50 for a vehicle includes a protective cover 41 , a rear surface cover 43 , a solar cell string 45 , and a sealing member 47 . The solar cell panel 50 for a vehicle is an example of the "solar cell panel" in the present invention. This vehicle solar cell panel 50 is used in a vehicle not shown, and is attached to a roof. In addition, the details of the protective cover 41 , the rear surface cover 43 , the solar cell strings 45 , and the sealing member 47 will be described later.

[0022] In this embodiment, the figure 1 The direction indicated as "front" in the middle is set to the front of the vehicle solar cell panel 50, and the figure 1 The direction indicated as "rear" in the middle is set to the rear of the solar cell panel 50 for a vehicle, and the front-rear direction of the solar cell panel for a vehicle 50 is defined. In addition, the figure 1 The direction indicated as “up” in the middle is set as the upper sid...

Embodiment 2

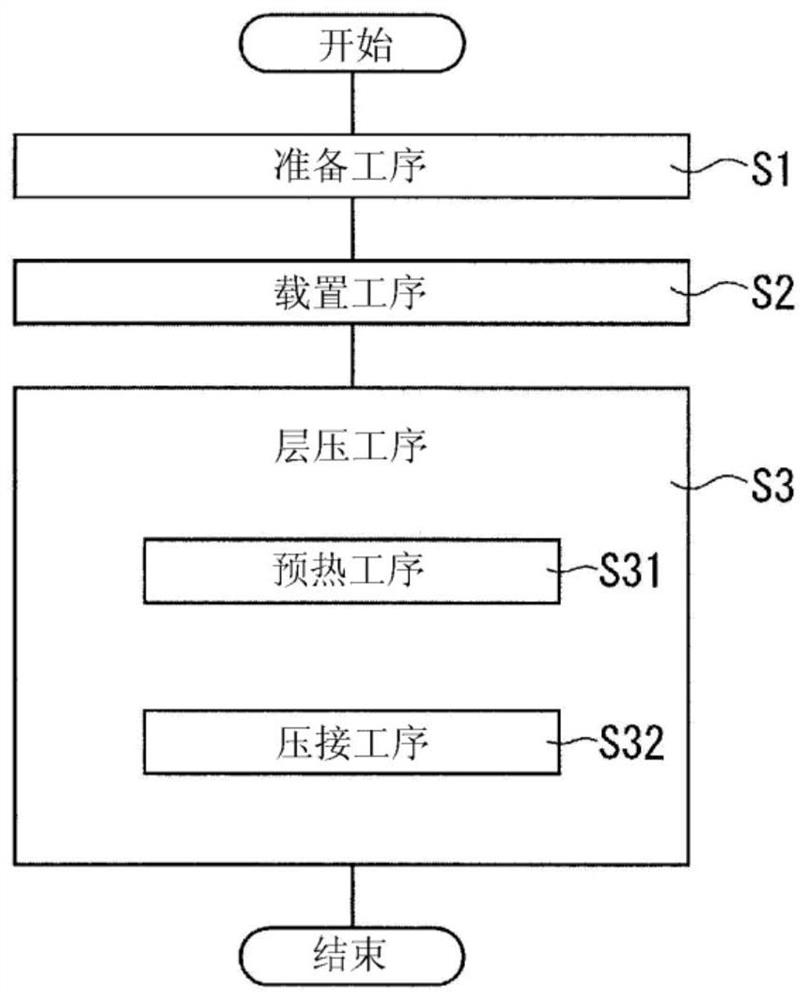

[0052] In the manufacturing method of Example 2, in the preparation step S1, the preparation Figure 8 Lamination device 101 is shown. In this lamination apparatus 101 , with respect to the support surface 310 of the lamination jig 3 , a stepped portion 310 a protruding toward the laminated body 40 is formed. In addition, the shape of the step portion 310a can be appropriately changed. Other structures in this manufacturing method, including other structures in the lamination apparatus 101, are the same as the manufacturing method of Example 1.

[0053] In this manufacturing method, in the crimping step S32, the rear cover 43 can be bent into a convex shape toward the protective cover 41, and the step 43c can be provided with respect to the bottom plate 43a of the rear cover 43 using the shape of the step portion 310a. In other words, in this manufacturing method, the product shape of the rear cover 43 is curved toward the protective cover 41 in a convex shape, and the step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com