An auxiliary tool for installing and disassembling indoor cable terminals

An auxiliary tool and indoor cable technology, which is applied in the direction of connection/termination cable equipment, switchgear, electrical components, etc., to achieve the effect of easy disassembly, saving physical strength and installation time, and fast installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

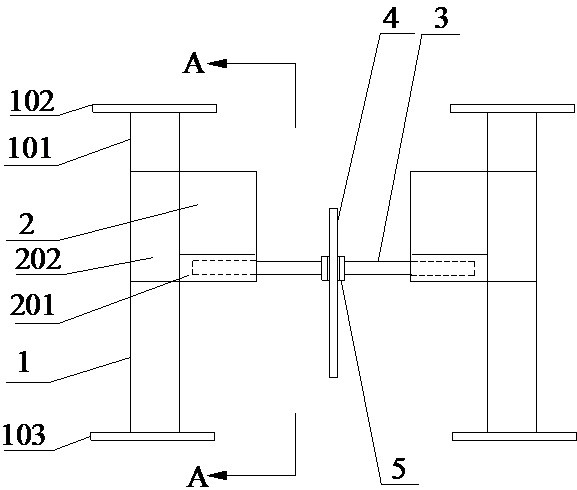

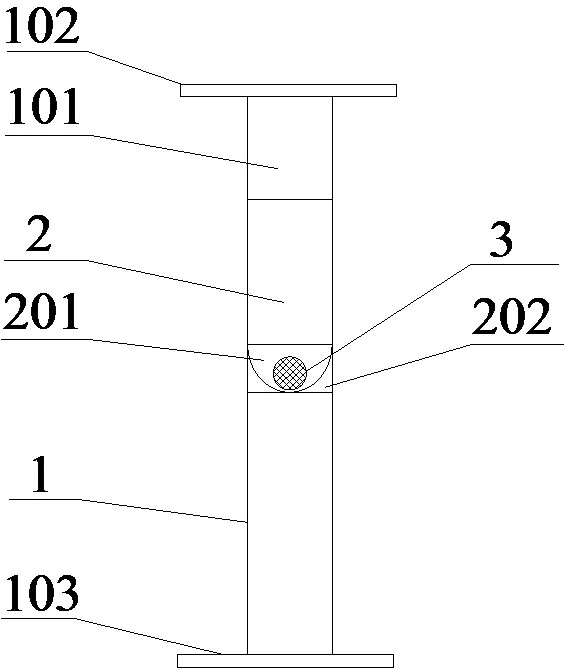

[0040] refer to Figure 1-4 , an auxiliary tool for installing and disassembling an indoor cable terminal, comprising a bracket 1, a pole 3 and a lever 4, the bracket 1 is a group, the bracket 1 includes a pole 101, a fulcrum 2 connected with the pole 101, and a pole arranged on the pole The upper support plate 102 and the lower support plate 103 at both ends of 101, the fulcrum 2 is provided with an arc-shaped deep hole groove 201, the end of the support rod 3 is arranged in the arc-shaped deep hole groove 201, and the support rod 3 is provided with a positioning card slot 5 , the lever 4 is set in the positioning slot 5 .

[0041] As a preferred embodiment of the present invention, the fulcrum 2 further includes a cylindrical portion 202 , the arc-shaped deep hole 201 is provided on the side of the cylindrical portion 202 , and the cylindrical portion 202 is screwed to the vertical rod 101 . In this way, the height position of the fulcrum 2 can be adjusted by rotating the c...

Embodiment 2

[0055] refer to Figure 1-5 , the indoor cable terminal assembly and disassembly auxiliary tool described in this embodiment is basically the same as that of Embodiment 1, the difference is:

[0056] The vertical rod 101 is composed of an upper vertical rod 1011 connected with a lower vertical rod 1012, and the fulcrum 2 is connected with the upper vertical rod 1011.

[0057] The upper pole 1011 is screwed to the lower pole 1012 .

[0058] The cylindrical portion 202 of the fulcrum 2 is screwed to the upper pole 1011 .

[0059] Through the above improvements, the height of the pole 101 can be changed by adjusting the connection between the upper pole 1011 and the lower pole 1012, and the fulcrum 2 can also be adjusted in height on the upper pole 1011, which has higher flexibility and adapts to environmental changes. stronger.

[0060] The method for using the auxiliary tool for installing and disassembling indoor cable terminals in this embodiment includes the following ste...

Embodiment 3

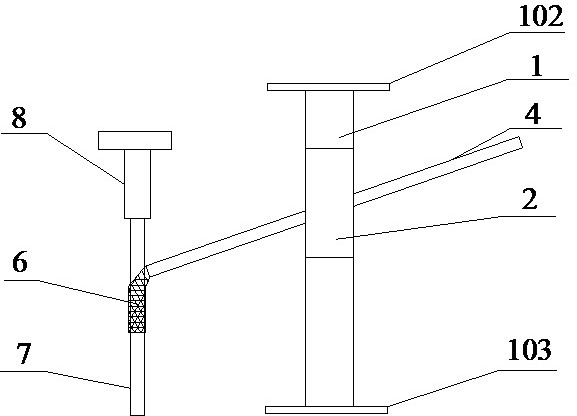

[0067] refer to Figure 6 , the indoor cable terminal assembly and disassembly auxiliary tool described in this embodiment is basically the same as that of Embodiment 2, the difference is:

[0068] One end of the lever 4 is provided with a handle 401 , and the other end is provided with a hook 402 .

[0069] Preferably, the handle 401 is provided with anti-slip components, such as anti-slip lines and anti-slip protrusions.

[0070] Through the above improvements, the lever 4 is easy to hold by the operator during operation, and is not easy to slip off; and the design of the hook 402 facilitates the fixing of the cable body 7 and the lever 4, which helps to improve the firmness of the connection between the two. Because the lever 4 has a slippery surface, it slipped off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com