Method for producing a multilayer conductor plate and conductor plate

A technology of multi-layer conductors and conductor plates, applied in the directions of multi-layer circuit manufacturing, printed circuit manufacturing, printed circuit components, etc., can solve problems such as the consumption of multi-layer conductor plates, and achieve the effect of simple cost and favorable manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

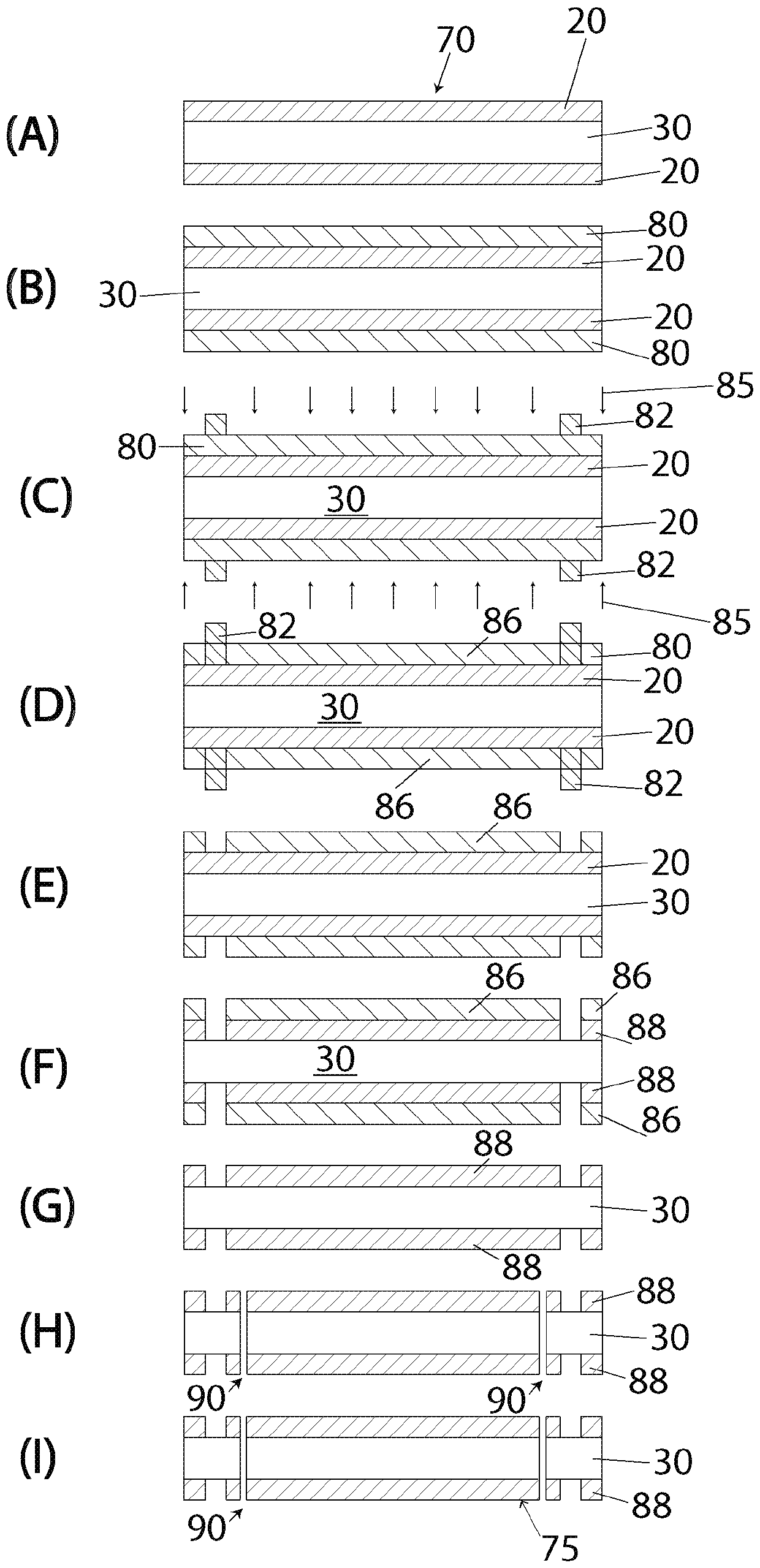

[0093] figure 1 The configuration or structuring of the outer layer 50 of the multilayer conductor plate, which is known per se from the prior art, is shown in steps (A) to (H).

[0094] Step (A) shows the outer layer 50 after cleaning performed previously (that is to say with the surface 70 already cleaned). The outer layer 50 here comprises an insulating film 30 , for example made of a prepreg material based on FR4. Furthermore, the outer layer 50 includes a conductive metal film 20 , which here is made, for example, of copper. The metal film 20 has been laminated on the insulating film 30 .

[0095] Step (B) shows the outer layer 50 after lamination with a photoresist film 80 which is arranged on the outside on the metal film 20 .

[0096] Step (C) shows the exposure of the photoresist film 80 through a mask or exposure template 82 arranged on the outside. The exposure of the photoresist film 80 by means of UV light passing through the openings of the exposure template ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com