Defoaming dispersion equipment for waterborne building coating

An architectural coating and dispersion technology, applied in the directions of foam dispersion/prevention, mixer, mixer with rotary stirring device, etc., can solve the problems of poor dispersion effect, waste of power, incomplete elimination of bubbles, etc., and achieve good defoaming effect. , the reaction is sufficient, the slurry dispersion effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

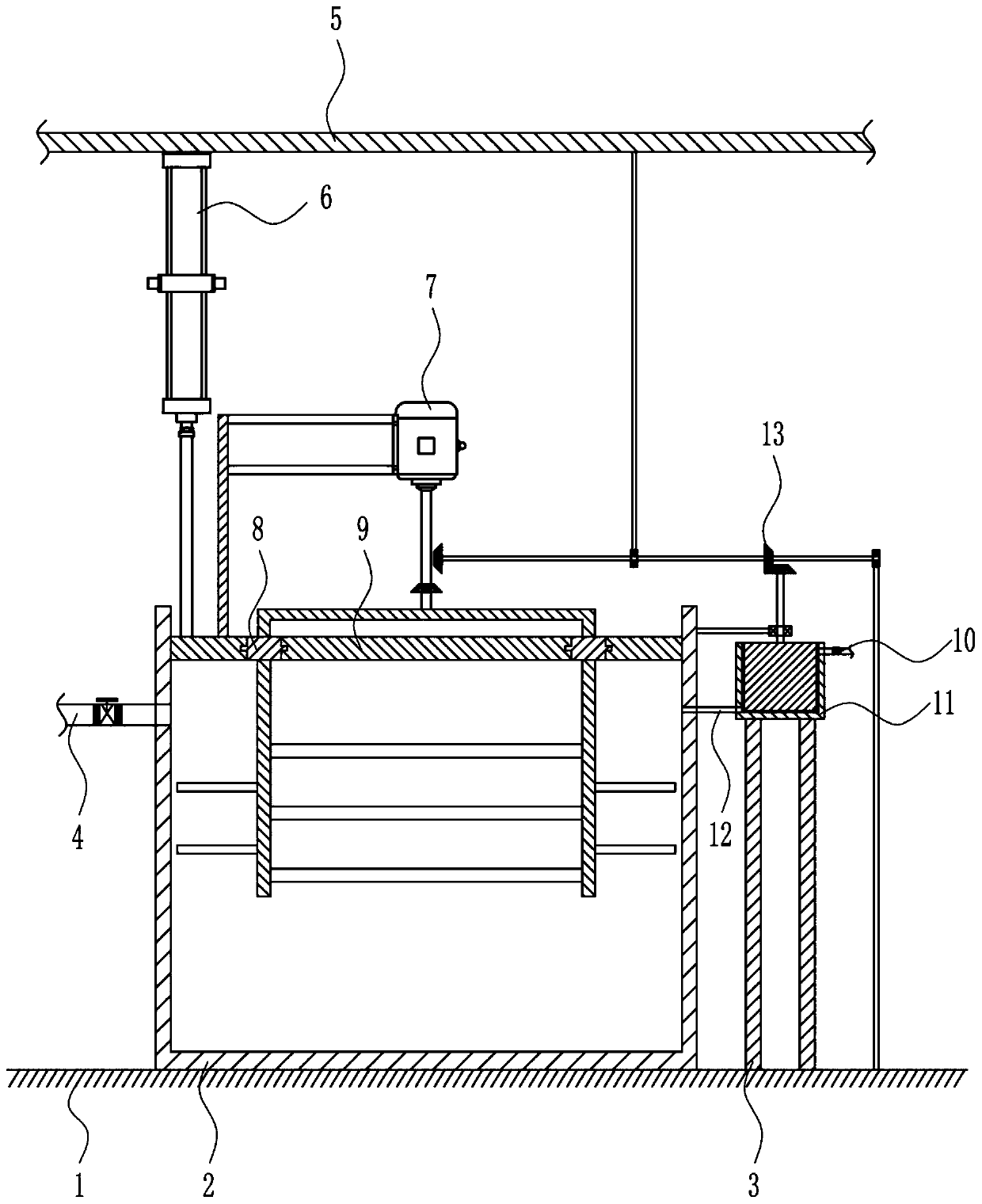

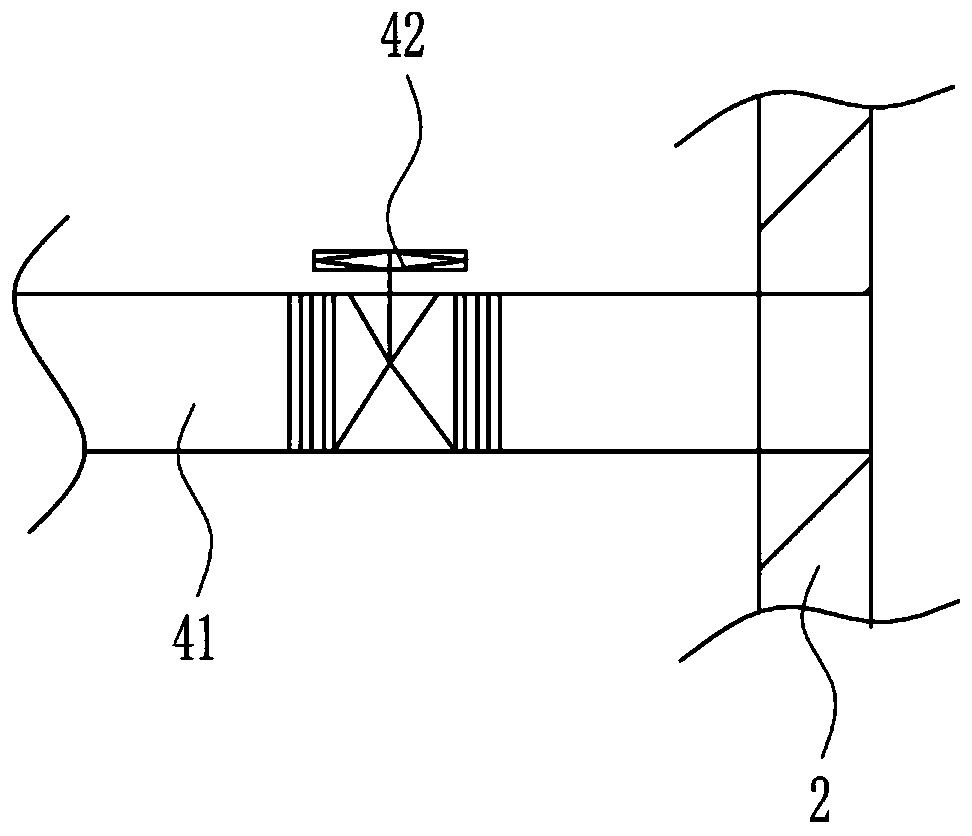

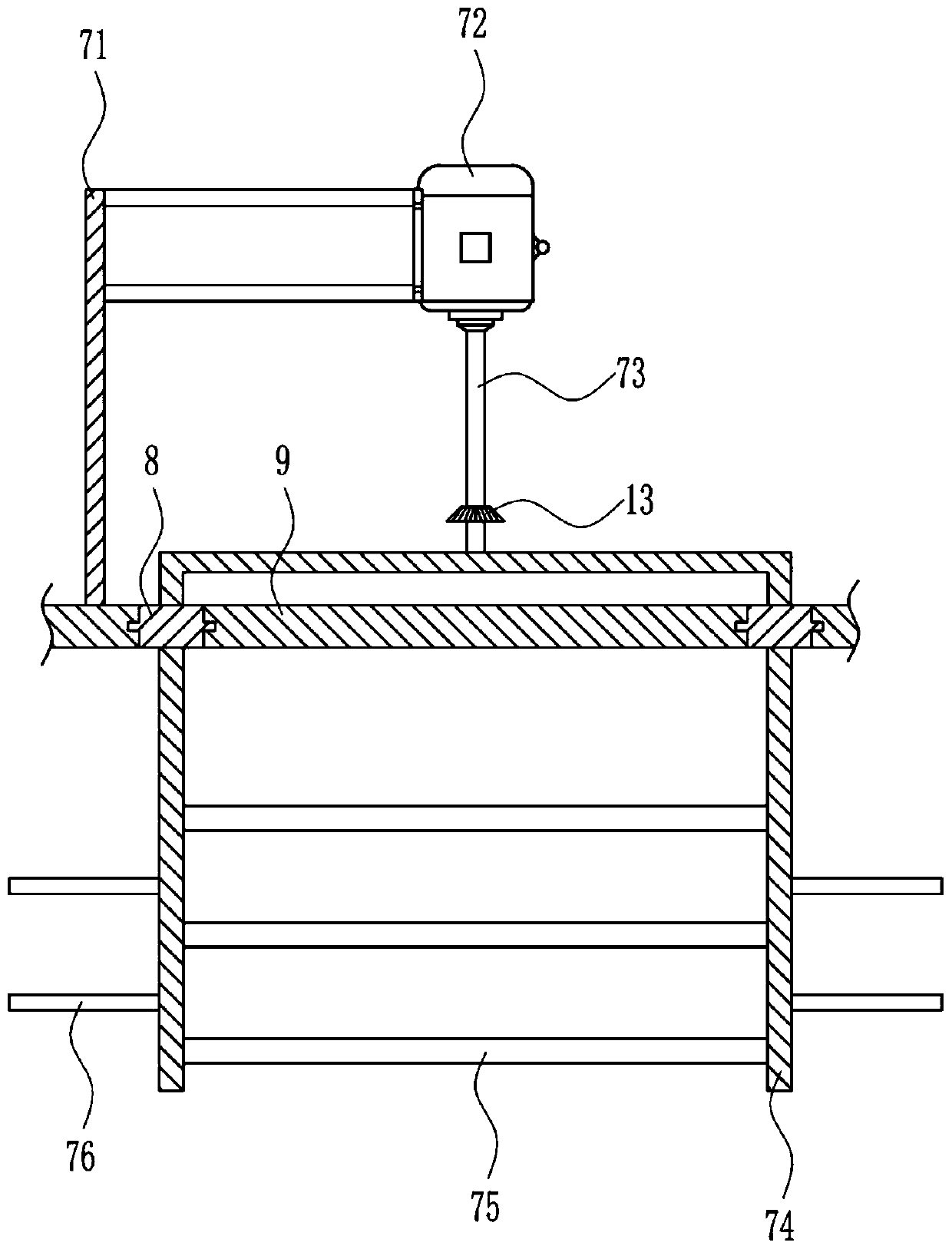

[0030] A kind of water-based architectural paint defoaming dispersion equipment, such as Figure 1-9 As shown, it includes a dispersing tank 2, a support rod 3, a first feeding mechanism 4, a frame 5, a cylinder 6, a dispersing mechanism 7, a sliding swivel 8, a sealing cover 9, a second feeding mechanism 10, and a box body 11 , a connecting pipe 12 and a pulverizing mechanism 13; a dispersing tank 2 is placed on the ground 1, a first feeding mechanism 4 is installed on the upper part of the left side wall of the dispersing tank 2, a sealing cover 9 is provided on the dispersing tank 2, and the sliding swivel 8 is connected with the sealing The cover 9 is slidingly connected; the sealing cover 9 is fixedly connected with a dispersing mechanism 7, and the lower part of the dispersing mechanism 7 passes through the sliding swivel 8 and extends into the dispersion tank 2; the ground 1 on the right side of the dispersion tank 2 is fixedly connected with a support rod 3, supporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com