Automatic pipe inserting and external sleeving assembling machine

A technology of assembling machines and jackets, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that the degree of automation needs to be further improved, and the realization of fully mechanized automatic production, etc., to achieve high accuracy, high production efficiency, Simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

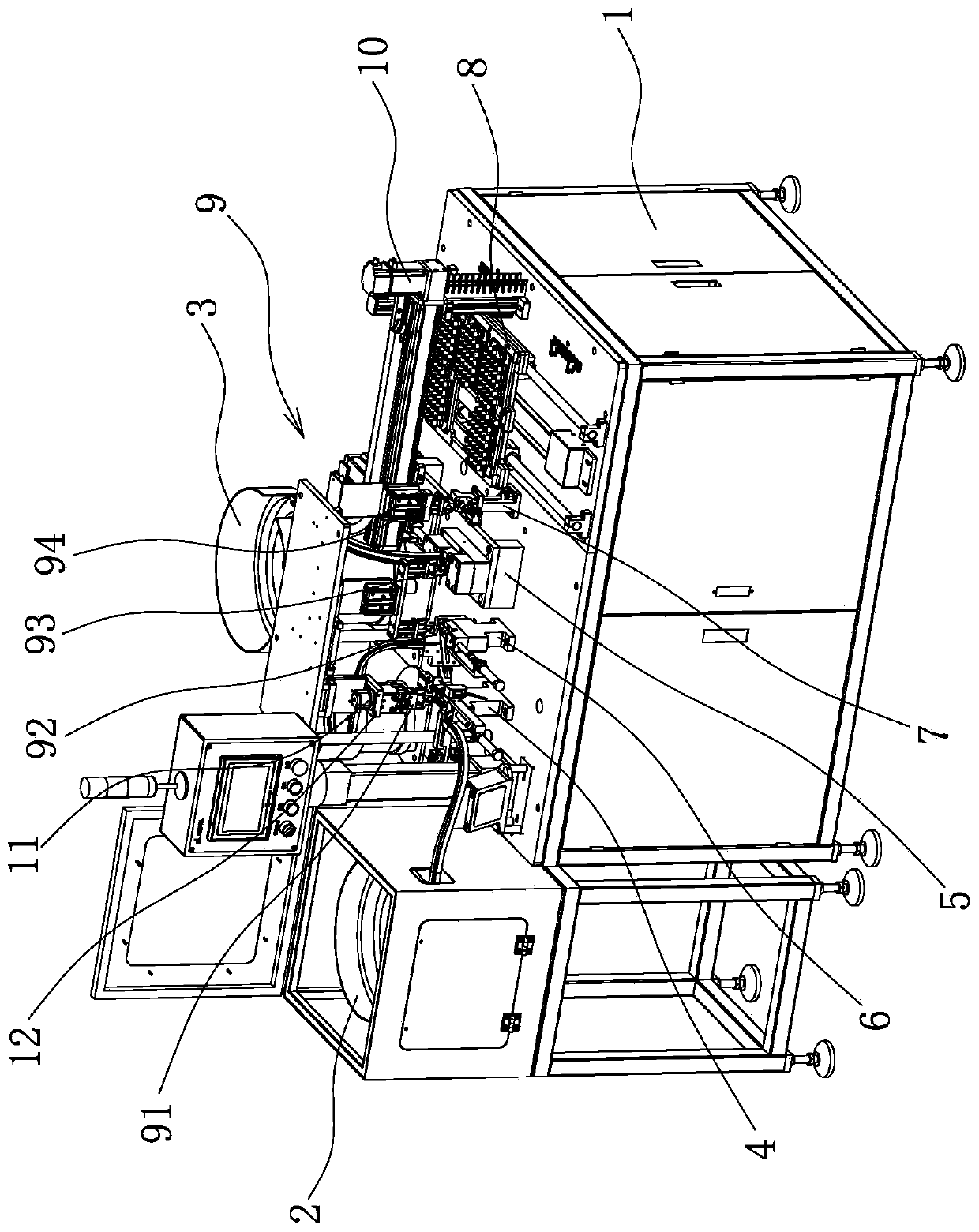

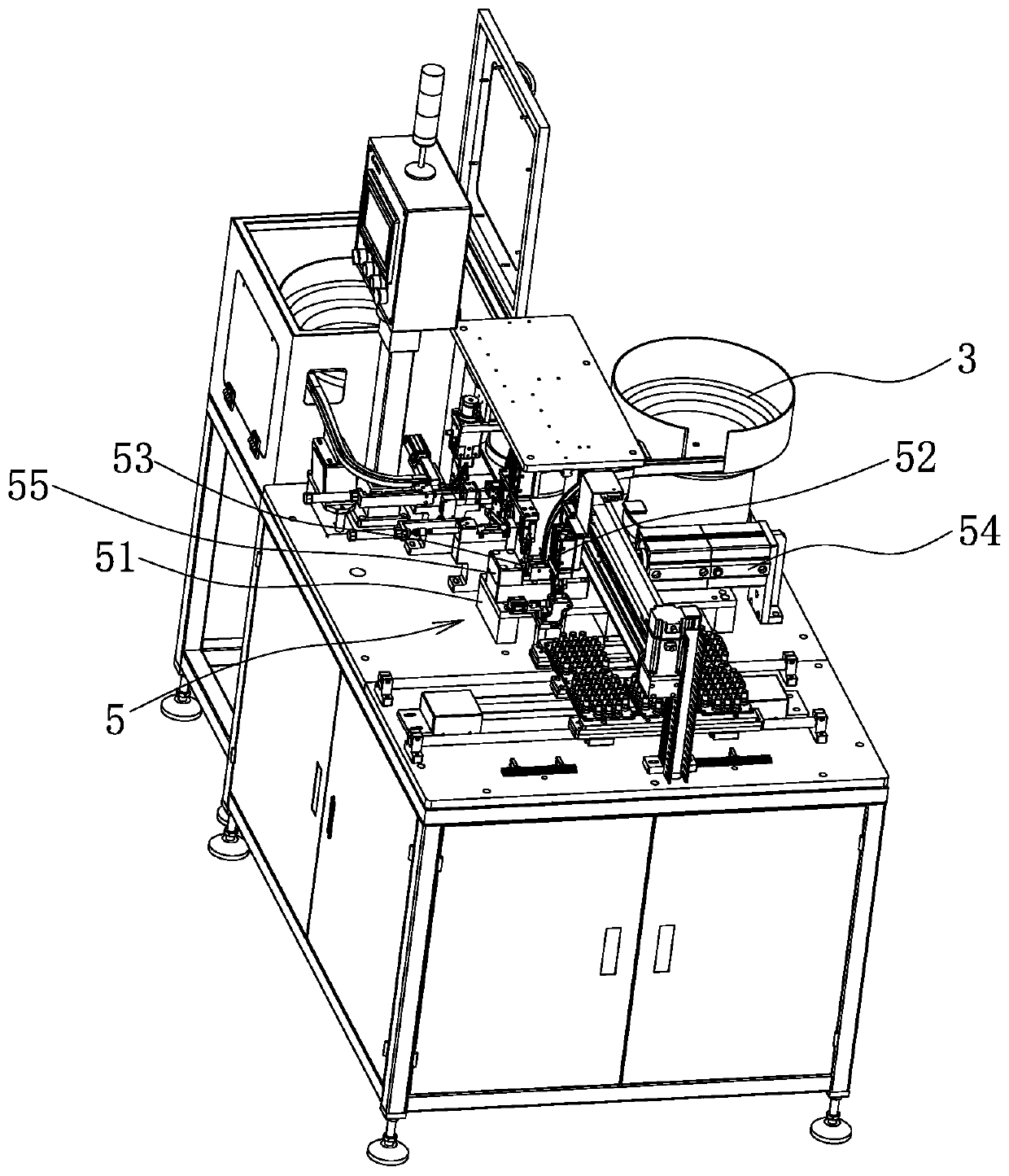

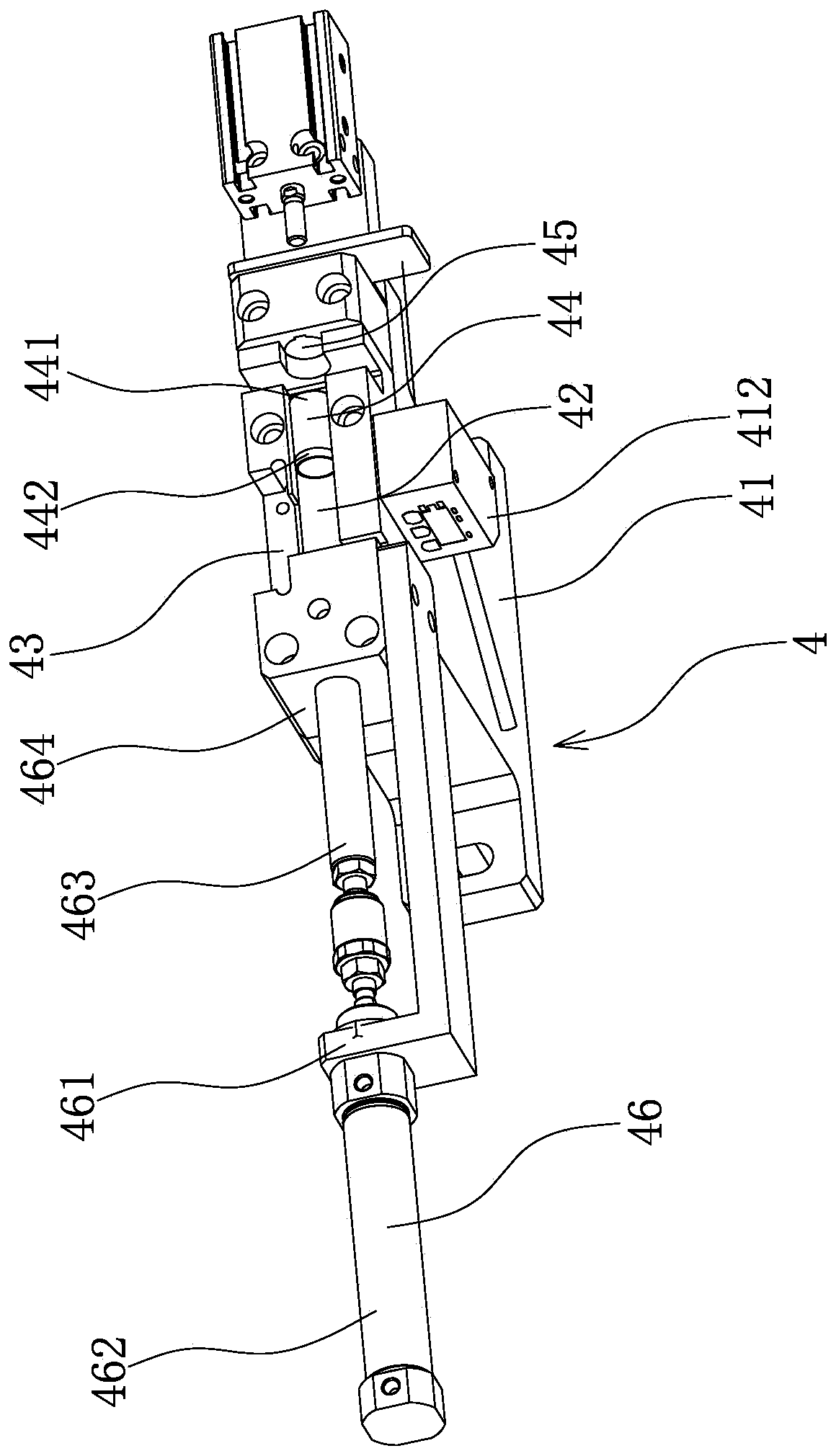

[0028] Such as figure 1 As shown, an automatic assembly machine for intubation sleeves includes a frame 1, and the frame 1 is provided with an inner cannula vibrating plate 2 and an outer cannula vibrating plate 3, and an inner cannula vibrating plate 2 and an outer cannula vibrating plate 3 Vibrating discs in the prior art can be selected, the inner tube vibrating disc 2 communicates with the direction detection assembly 4, the outer tube vibrating disc 3 communicates with the press-fit assembly 5, and the frame 1 Also be provided with collar assembly 6, overturning assembly 7 and storage assembly 8, pneumatic gripper 9 is slidingly connected with frame 1, and described pneumatic gripper 9 is in direction detection assembly 4, collar assembly 6, pressing Move between the assembly assembly 5, the turning assembly 7 and the storage as...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap