Automatic coding system and method for box-splitting-type quick-change battery

An automatic coding and battery replacement technology, which is applied in transmission systems, electric vehicles, digital transmission systems, etc., can solve the problems of low efficiency of quick battery replacement, and achieve the effects of improving efficiency, reducing workload, and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

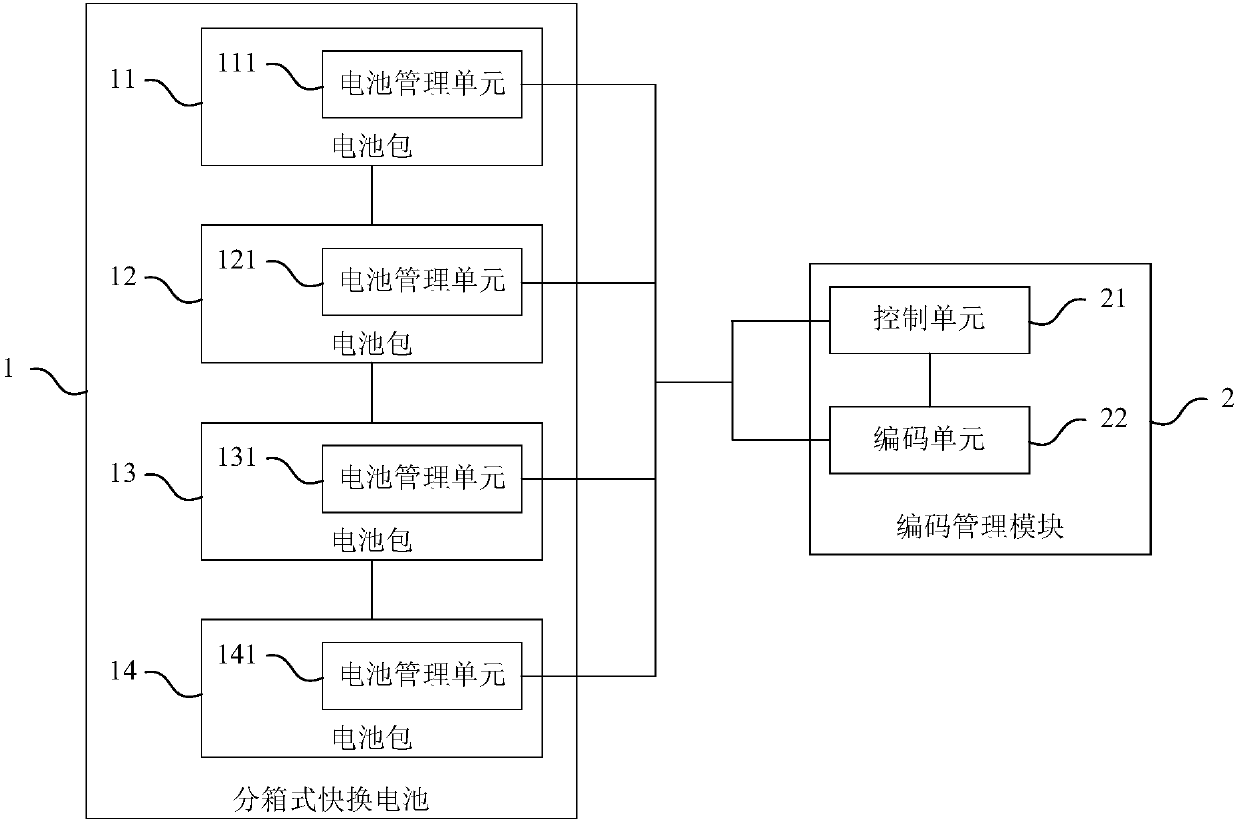

[0045] figure 1 A schematic structural diagram of the automatic coding system for the box-type quick-change battery of this embodiment is shown. refer to figure 1 , the automatic coding system of the box-type quick-change battery of this embodiment includes a box-type quick-change battery 1 and a coding management module 2, wherein the box-type quick-change battery 1 includes a battery pack 11, a battery pack 12, and a battery pack 13 And the battery pack 14, the battery pack 11 includes a battery management unit 111, the battery pack 12 includes a battery management unit 121, the battery pack 13 includes a battery management unit 131, the battery pack 14 includes a battery management unit 141, the encoding management module 2 is arranged on the vehicle and Including the control unit 21 and the encoding unit 22 , the battery management units 111 , 121 , 131 and 141 are communicatively connected with the control unit 21 and the encoding unit 22 through the CAN bus.

[0046] S...

Embodiment 2

[0053] The automatic coding system of the box-type quick-change battery in this embodiment is a further improvement on Embodiment 1. specifically:

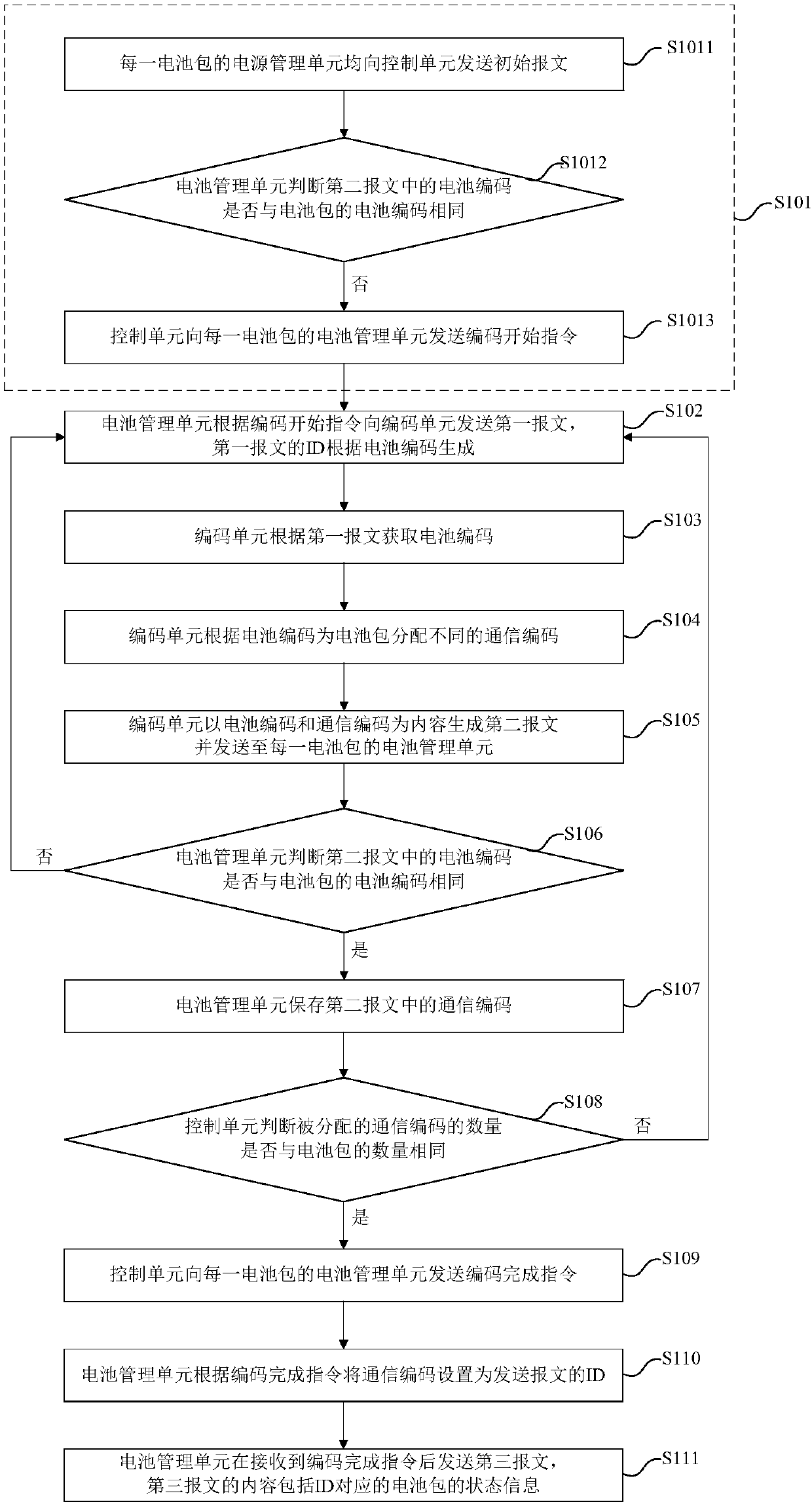

[0054] At the beginning of power-on, the battery management units 111, 121, 131 and 141 send initial messages to the control unit 21, and the control unit 21 includes a counter (not shown in the figure), which is used to count the number of IDs sending initial messages, and control Unit 21 is used to judge whether the number of IDs obtained by statistics is the same as the number of battery packs. If they are the same, it means that the initial code of the battery pack is normal and can communicate normally, and there is no need to re-encode the battery pack; if it is different, it means the same If there is a battery pack with the same code in the battery pack and the communication cannot be normal, the battery pack needs to be coded again. In this case, the control unit 21 sends a code start command to the battery management uni...

Embodiment 3

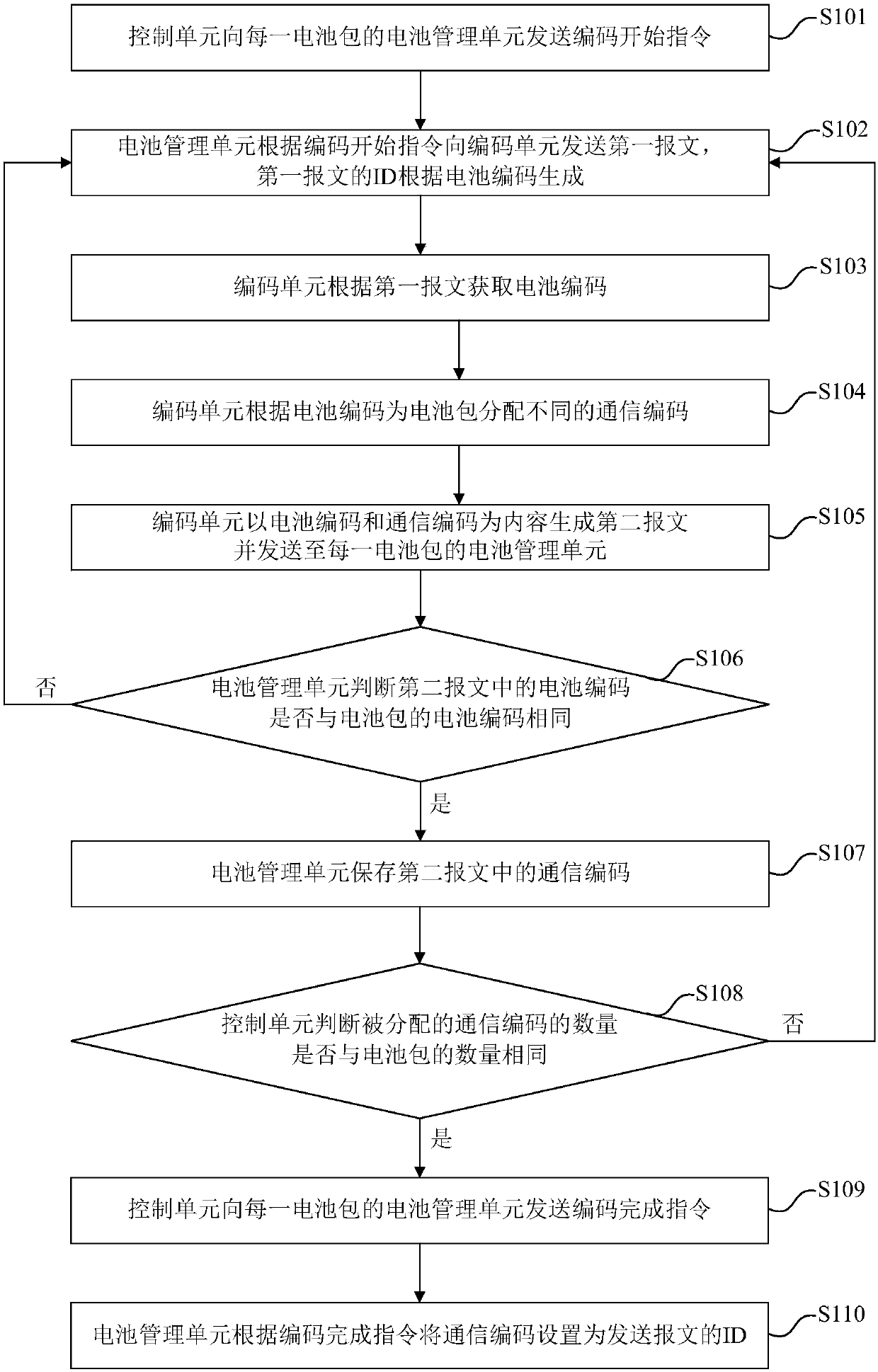

[0060] The automatic coding method of the sub-box type quick-change battery of the present embodiment is realized by the automatic coding system of the sub-box type quick-change battery of embodiment 1, figure 2 shows the flowchart of this embodiment, refer to figure 2 , this embodiment includes the following steps:

[0061] S101. The control unit sends an encoding start instruction to the battery management unit of each battery pack;

[0062] S102. The battery management unit sends the first message to the encoding unit according to the encoding start instruction, and the ID of the first message is generated according to the battery code;

[0063] S103. The coding unit acquires the battery code according to the first message;

[0064] S104. The coding unit assigns different communication codes to the battery pack according to the battery code;

[0065] S105. The coding unit generates a second message based on the battery code and the communication code and sends it to th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap