Construction method for heat treatment of bainite steel rail joint after welding

A construction method and bainite technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as the question of heat treatment effect, and achieve the effect of avoiding wear and eliminating accumulation factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

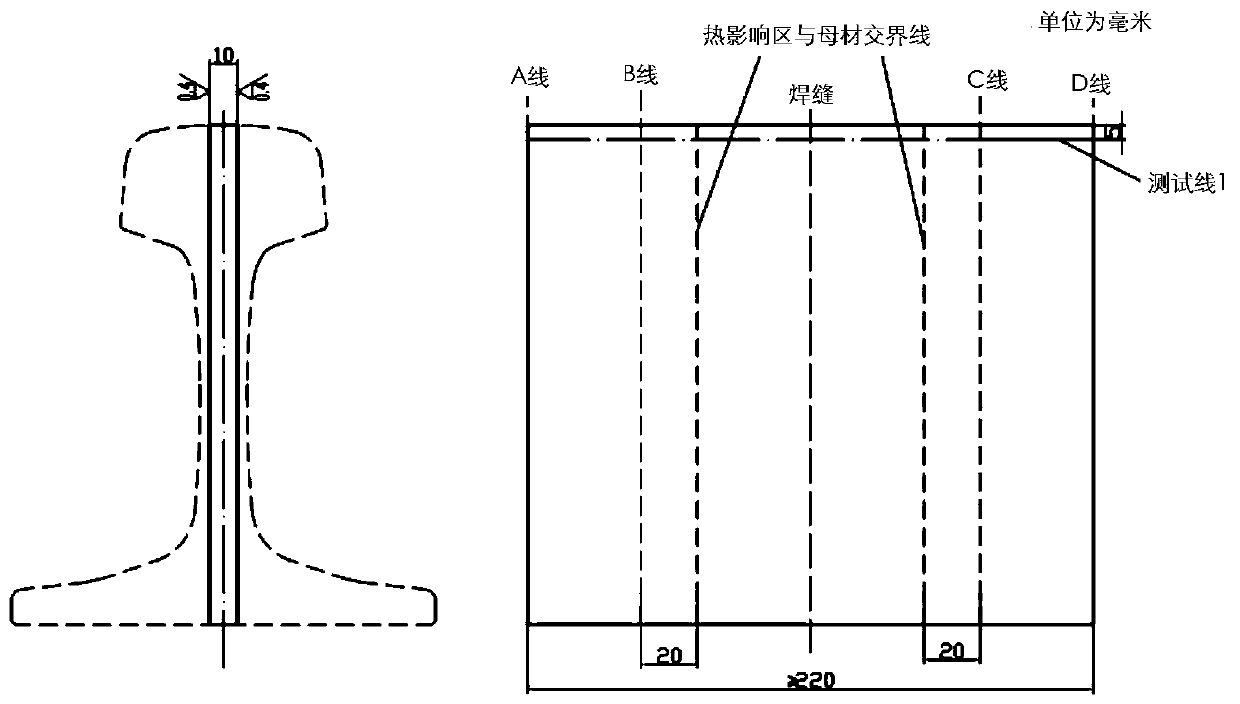

[0039] According to conventional methods, after welding of heat-treated bainitic rails, there are phenomena such as low tread hardness and poor toughness in the welded area, and normalizing heat treatment is usually required to improve joint performance. However, after normalizing, the welded joint has low hardness and widened softening zone, which is easy to cause "saddle-shaped" wear of the welded joint during service, resulting in poor service performance. Based on this, the work of the present invention finds and designs a post-weld heat treatment method for heat-treated bainite rails, which ensures the service life of rail joints while ensuring the hardness of the joint tread.

[0040] Specific embodiments of the present invention will be described in detail below. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0041] In the present ...

Embodiment 1

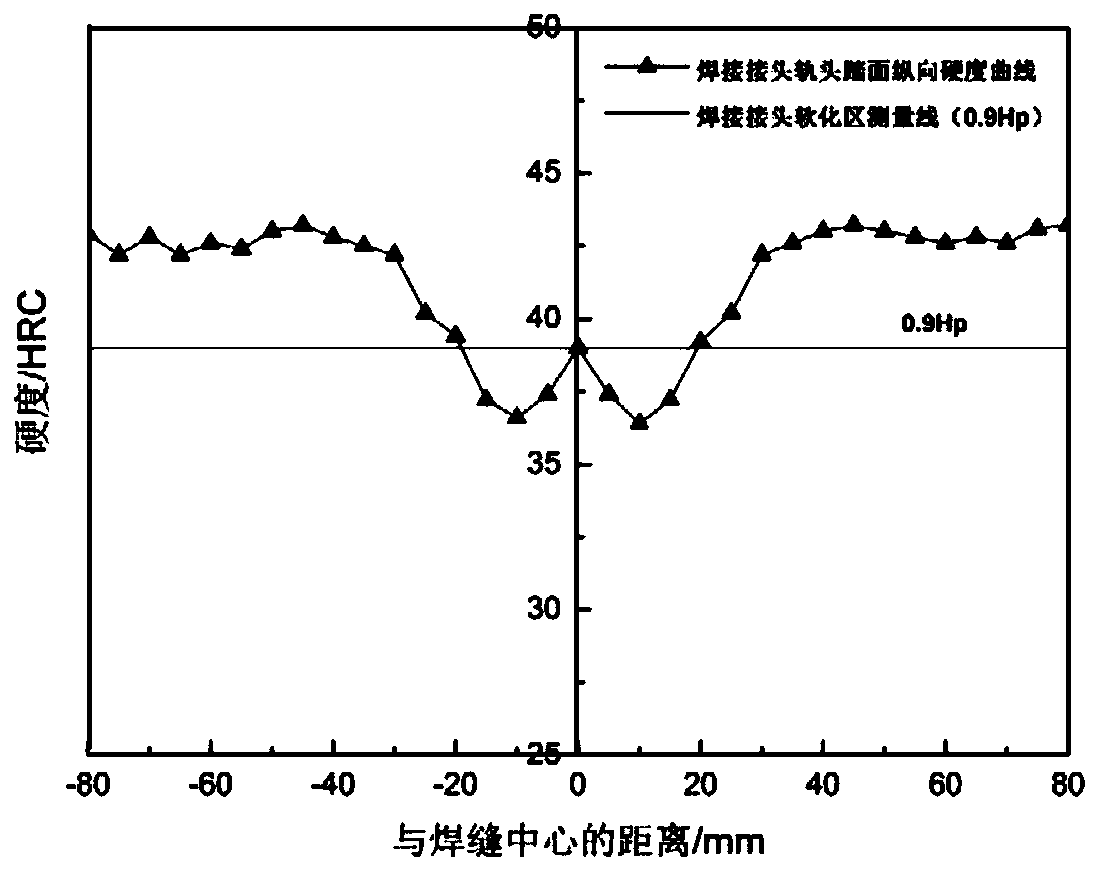

[0059] After the rail with a specification of 68kg / m has completed the upsetting and push-out during the mobile flash welding process, the welded joint is subjected to post-weld heat treatment. Firstly, the rail joint with residual temperature of 1100 °C after welding is cooled in the first stage at the first cooling rate of 4.5 °C / s to reduce the surface temperature of the rail head of the rail joint to 700 °C, and then the rail joint is cooled at 2.0 °C The second cooling rate of 0.4 °C / s is used for the second-stage cooling to reduce the surface temperature of the rail head of the rail joint to 200 °C, and finally the third cooling rate of 0.4 °C / s is used for the third-stage cooling of the rail joint to reduce the temperature of the rail joint The temperature of the surface layer of the rail head is lowered to the room temperature of 25° C., thereby obtaining the welded joint of the rail with post-weld heat treatment of the present invention. Among them, the first cooling ...

Embodiment 2

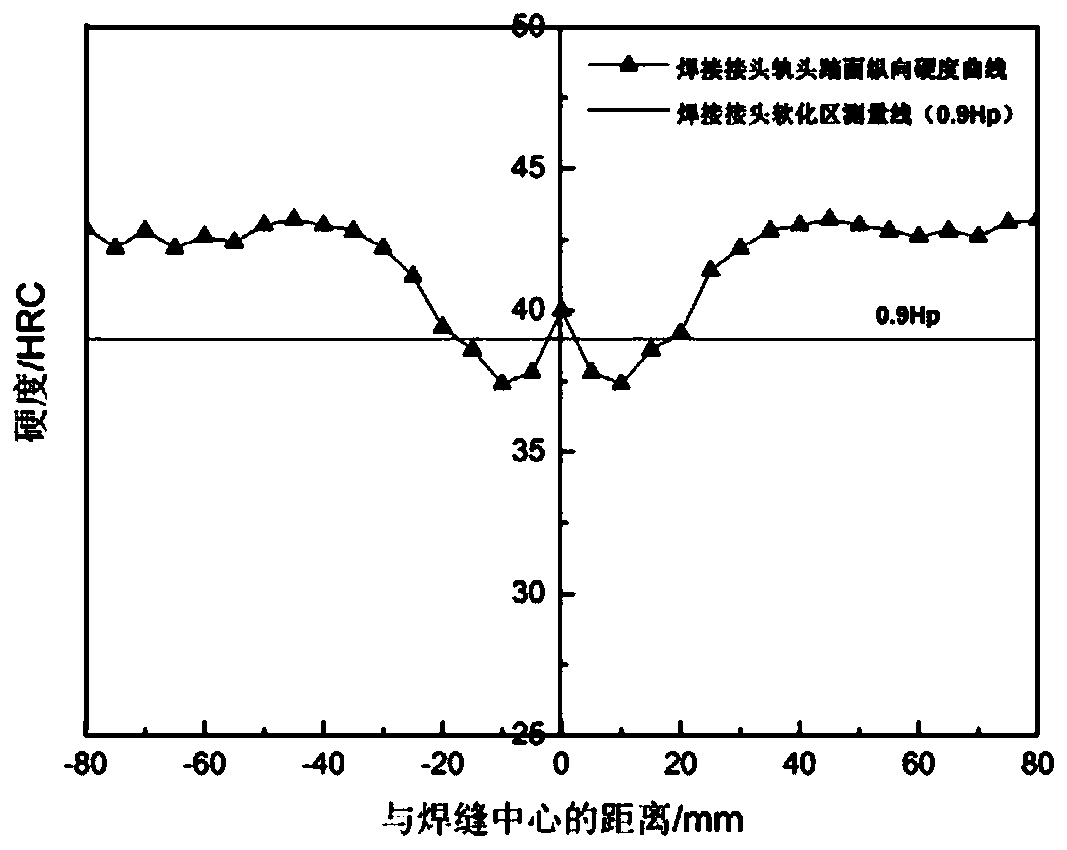

[0067] After the rails with a specification of 60kg / m have completed upsetting and push-out during the mobile flash welding process, the welded joints are subjected to post-weld heat treatment. Firstly, the rail joint with residual temperature of 1200 °C obtained by welding is cooled in the first stage at the first cooling rate of 4.5 °C / s to reduce the surface temperature of the rail head of the rail joint to 650 °C, and then the rail joint is cooled at 2.5 °C The second cooling rate of / s is used for the second-stage cooling to reduce the surface temperature of the rail head of the rail joint to 180°C, and finally the rail joint is subjected to the third-stage cooling at a third cooling rate of 0.10°C / s to reduce the temperature of the rail joint The temperature of the surface layer of the rail head is lowered to the room temperature of 25° C., thereby obtaining the welded joint of the rail with post-weld heat treatment of the present invention. Among them, the first cooling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com