Glass slide flat dyeing device

A technology for glass slides and glass slides, which is applied in the field of slide flat dyeing devices, can solve the problem of glass slides falling, dripping on laboratory countertops, floors, sink surfaces, in incubators, contaminating the skin of staff and Clothing and other issues to achieve the effect of resisting dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

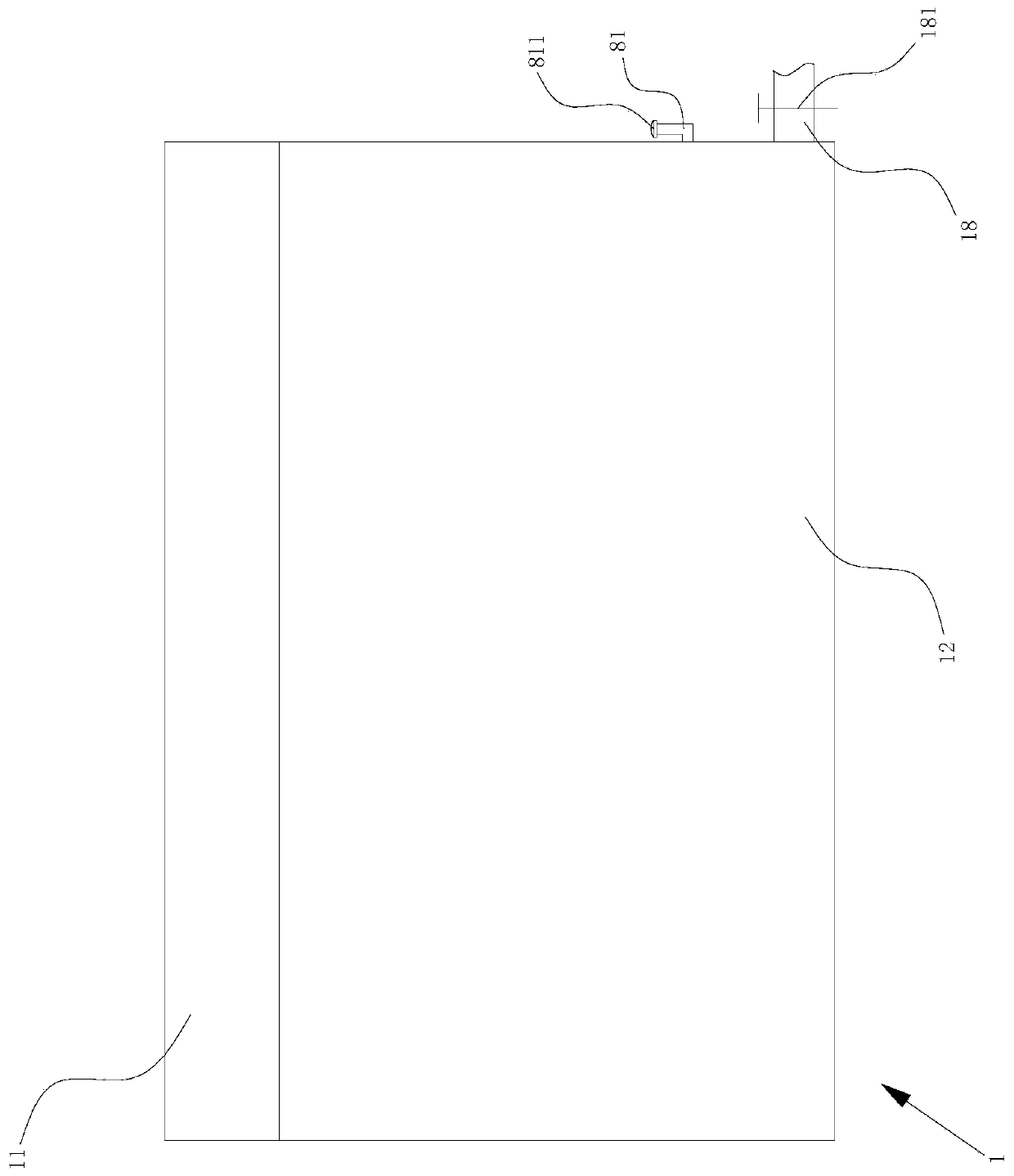

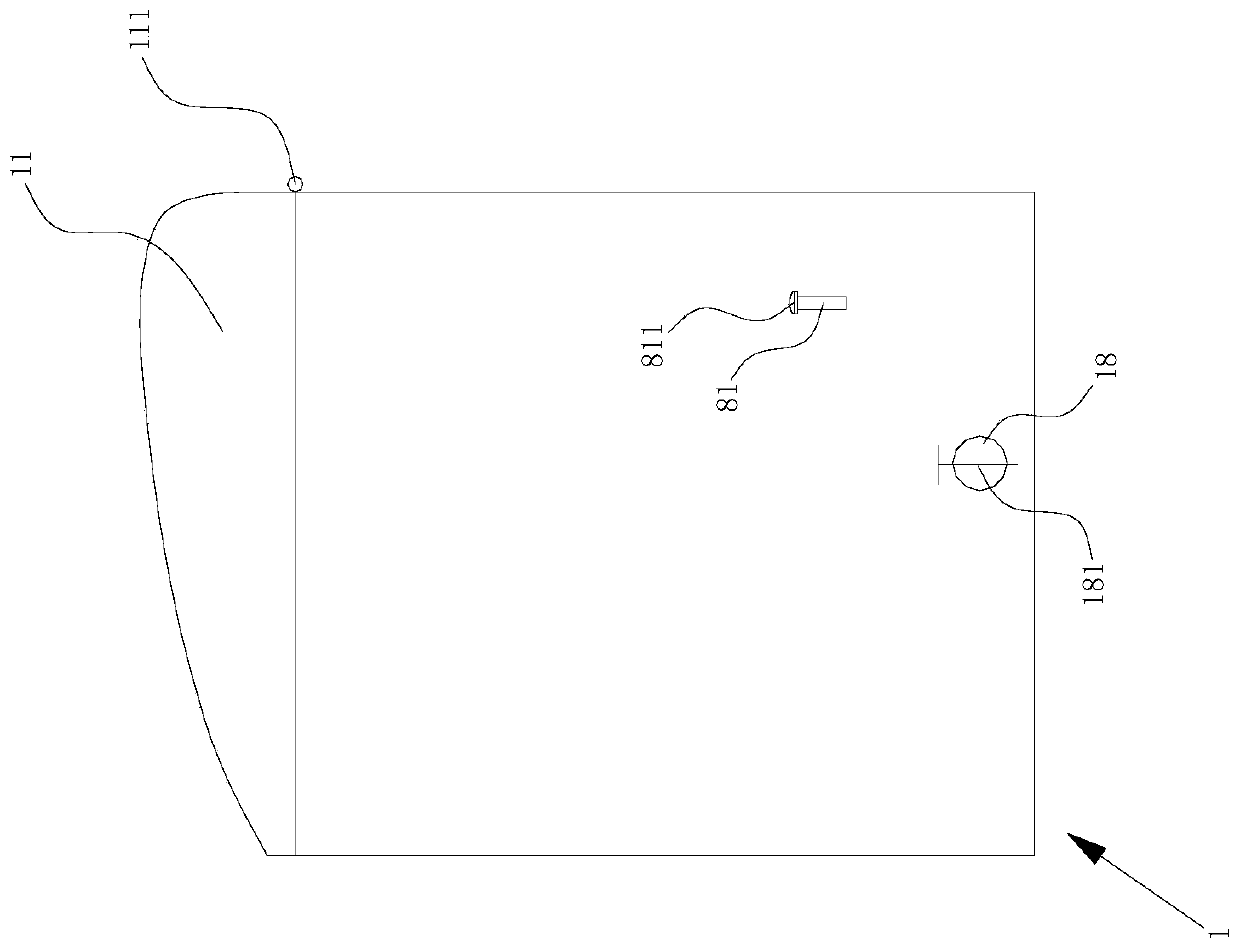

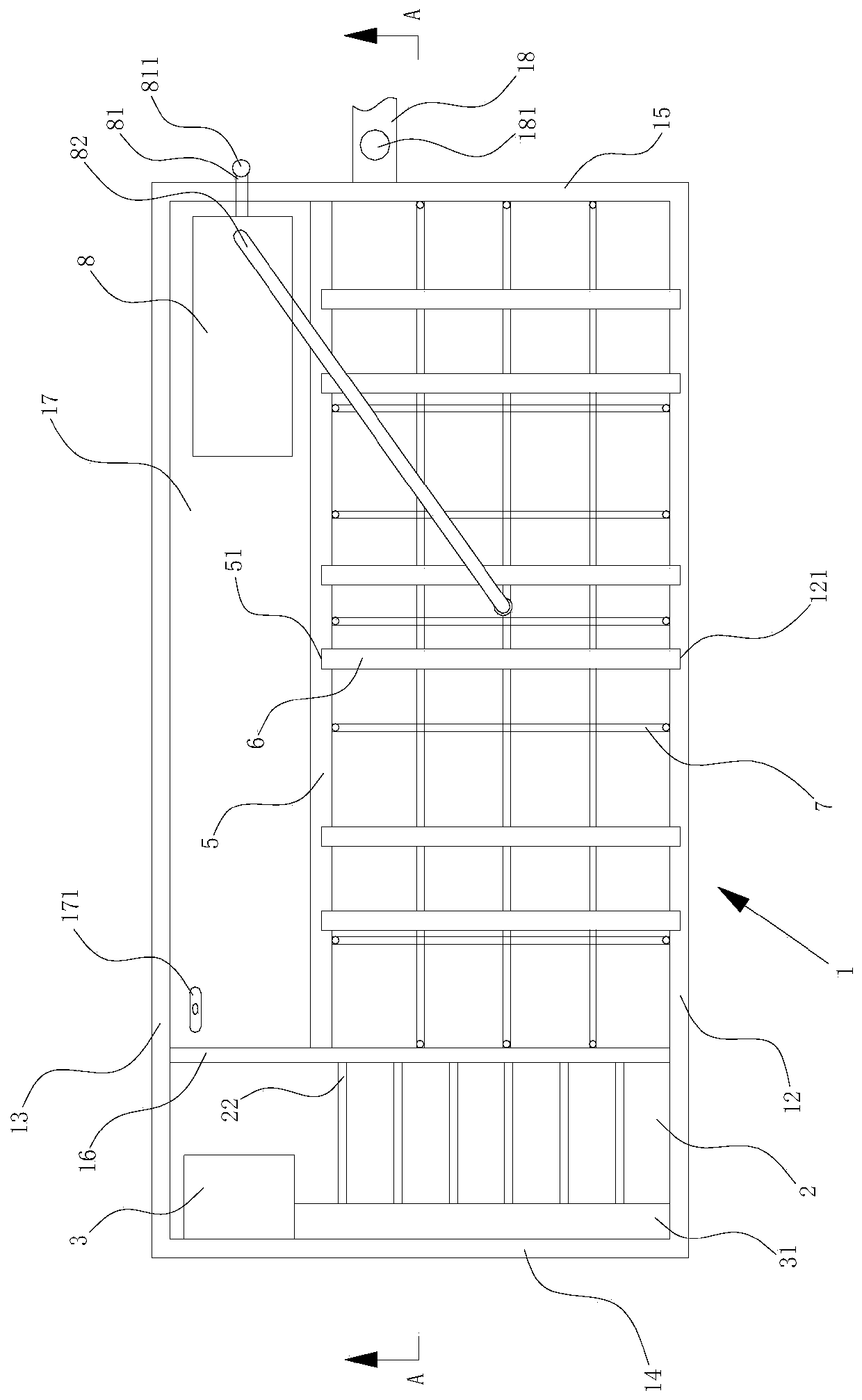

[0030] see Figure 1-Figure 5 , a flat dyeing device for slides, which includes a rectangular box body 1 whose length direction is left and right and whose upper side is open, an upper cover 11 is hinged on the upper side of the box body 1, and the hinged seat 111 is located on the rear side of the upper cover 11 , the box body 1 includes a front side wall 12, a rear side wall 13, a left side wall 14, and a right side wall 15;

[0031] The middle and upper area on the left side of the box body 1 is flexibly connected with a rectangular film rack 2 moving forward and backward. A strip-shaped convex strip 211 running left and right is respectively provided, and a strip-shaped convex strip 211 corresponding to each strip-shaped convex strip 211 is provided on the front side and the rear side of the drying rack 2. The matching chute 21, the film drying rack 2 is slidingly matched with the elongated convex strip 211, and the electric heating wire 23 is arranged in the film drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com