Automated production line monitoring system

An automated production line and monitoring system technology, applied in the general control system, control/adjustment system, program control, etc., can solve the problems that the monitoring effect cannot meet the production demand, and the effective analysis of the influencing factors of the automatic production process can not be achieved, so as to achieve effective The effect of monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

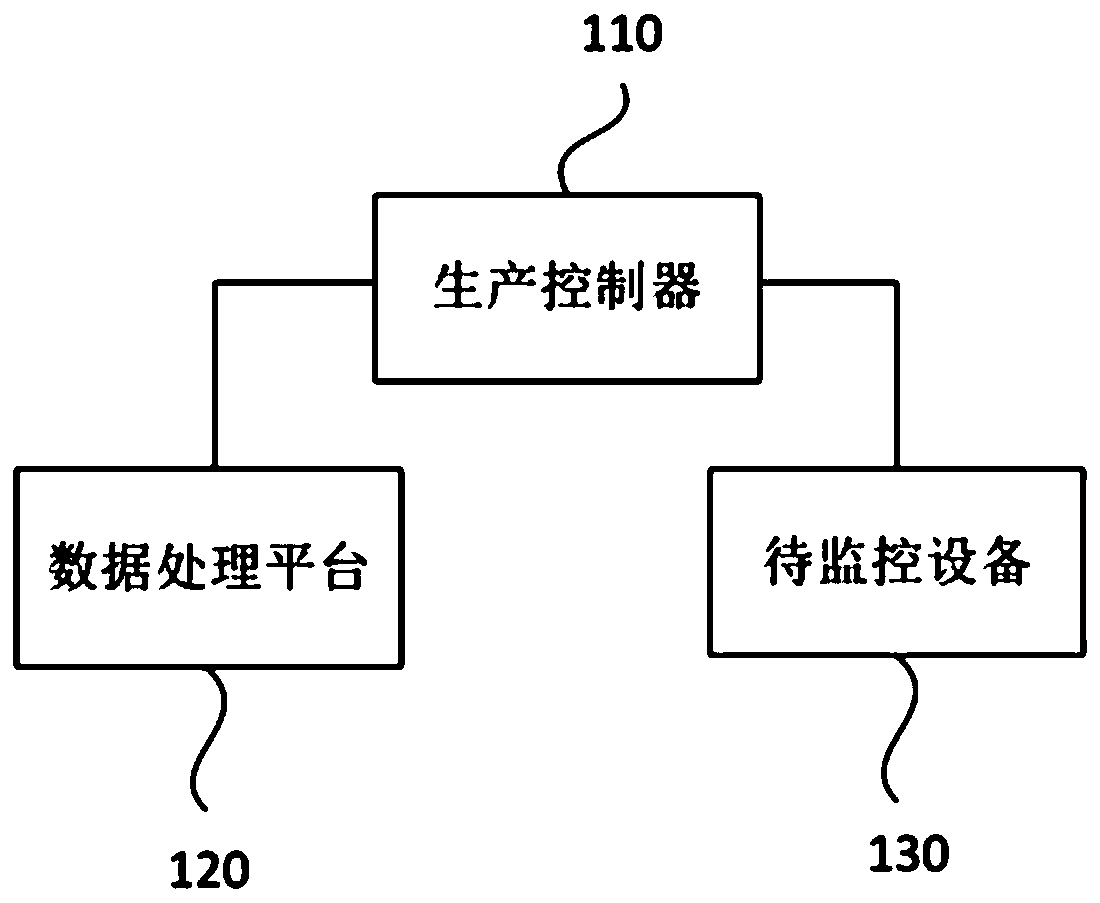

[0028] figure 1 It is a flow chart of an automated production line monitoring system provided by Embodiment 1 of the present invention. This embodiment is applicable to the situation of monitoring the automated production line when the automated production line performs processing tasks. The system can be realized by software and / or hardware. refer to figure 1 , the automated production line monitoring system includes: a production controller 110 , a data processing platform 120 and a device to be monitored 130 .

[0029] Wherein, the production controller 110 and the equipment to be monitored 130 are connected through network communication, for example, the production controller 110 and the equipment to be monitored 130 can be connected through MELSEC NET / H. The production controller 110 is used to control the equipment to be monitored 130 to perform processing tasks, and collect the current operating status information of the equipment to be monitored 130 and the equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com