Simulation experimental device for push-loose process of scraper conveyor under downhole complex ground condition

A scraper conveyor and experimental device technology, applied in teaching models, educational tools, instruments, etc., can solve problems such as single function, poor comprehensiveness, and lack of deep analysis of the connection constraints of the three machines, and achieve intuitive mechanisms and high work freedom Accurate, convenient data collection and operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] specific implementation plan

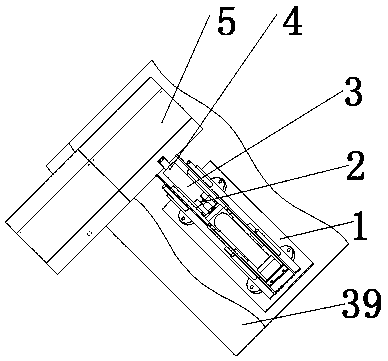

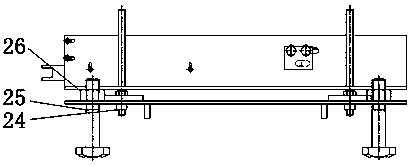

[0028] In the actual environment, the different cutting trajectories of the shearer will cause changes in the terrain on the moving path, so the paths that need to be passed each time for moving and moving are different and uneven. In order to simulate this complex ground condition and make the experimental device adapt to this change and operate, the designed experimental device is equipped with a height-adjustable foot cup on the base of the hydraulic support. The height adjustment of the foot cup can change the inclination of the base of the hydraulic support. Simulate the initial posture of the hydraulic support under actual ground conditions. In addition, a rubber layer with a high similarity to the coal seam is equipped at the bottom of the scraper conveyor, and the irregular ground in the real environment is simulated through the undulating state of the rubber layer. The structure and parameters of the experimental device are close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com