Resin composition for adhesive and adhesive sheet

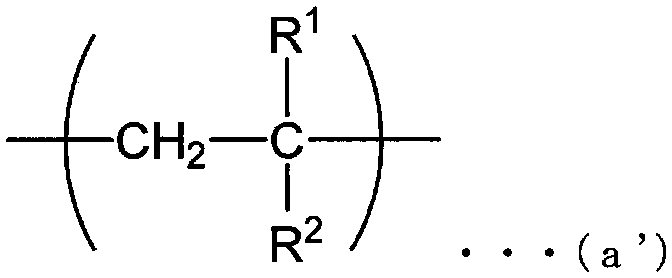

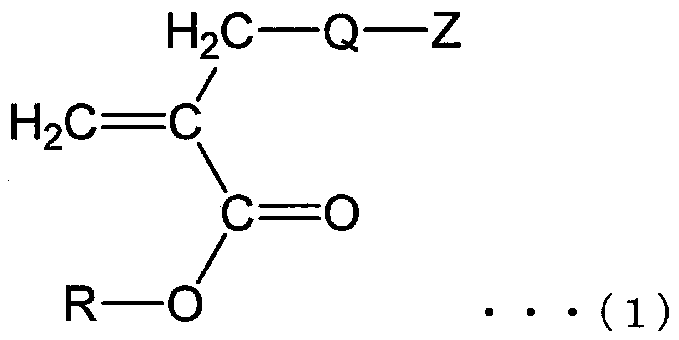

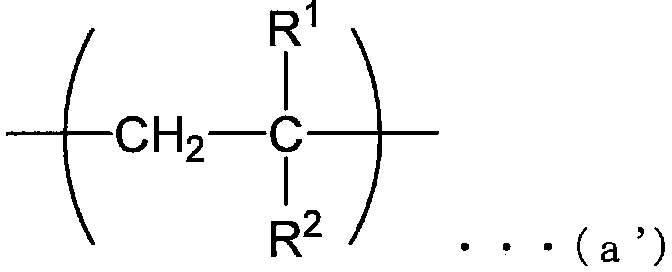

A technology of resin composition and adhesive, which is applied in the direction of adhesive, adhesive type, ester copolymer adhesive, etc., and can solve the problem of damage to the characteristics of vinyl monomer units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0379] Hereinafter, the present invention will be explained in further detail through examples, but the following examples do not limit the scope of the present invention. In the following examples, "parts" means "parts by mass".

[0380] The measurement method used in each example is shown below.

[0381]

[0382] (Number average molecular weight of macromonomer)

[0383] The number average molecular weight (Mn) of the macromonomer is measured using a gel permeation chromatography (GPC) device (manufactured by Tosoh Corporation, HLC-8320). A 0.2% by mass tetrahydrofuran (THF) solution of the macromonomer was prepared, and 10 μL of the above solution was injected into the above-mentioned device equipped with Tosoh Corporation’s columns (TSKgel SuperHZM-M×HZM-M×HZ2000, TSKguardcolumn SuperHZ-L) to Flow rate: 0.35 mL / min, eluent: THF (stabilizer: butyl hydroxytoluene (BHT)), column temperature: 40° C. The measurement was performed, and the number average molecular weight was calculat...

manufacture example 2~9

[0412] The solvent (dropping solvent) and monomer (dropping monomer) in the mixture of initial addition of solvent, initial addition of monomer, and dropwise addition after heating are changed as shown in Table 2. In addition, the same as the examples 1 In the same manner, copolymer solutions (A-2) to (A-9) were obtained.

[0413] The weight average molecular weight (Mw) of the copolymer in the copolymer solution obtained from each example, the half-width X of the one-dimensional scattering peak in the small-angle X-ray scattering measurement (SAXS) and the peak position Y of the one-dimensional scattering pattern are shown in the table 2 in.

[0414]

[0415] 80 parts of the copolymer solution (A-1) was desolvated so that the solid content became 99% or more, 60 parts of isodecyl acrylate (IDAA), crosslinking agent (PETA: Shin Nakamura Chemical, trade name "NK ESTER TMM-3L", pentaerythritol triacrylate) 10 parts, photopolymerization initiator (manufactured by BASF, trade name "IR...

Embodiment 2

[0436] Except that the copolymer used was changed to the copolymer described in Table 3, the same procedure as in Example 1 was carried out to prepare an adhesive resin composition to prepare an adhesive sheet, and evaluate the adhesive force, retention force, and resistance to substrate Polluting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com