Rapid pressure relief mechanism of electric pressure cooker and control method

The technology of an electric pressure cooker and a control method, which is applied in the field of pressure vessels, can solve problems such as safety of blocked exhaust passages, hidden dangers, troublesome cleaning by users, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

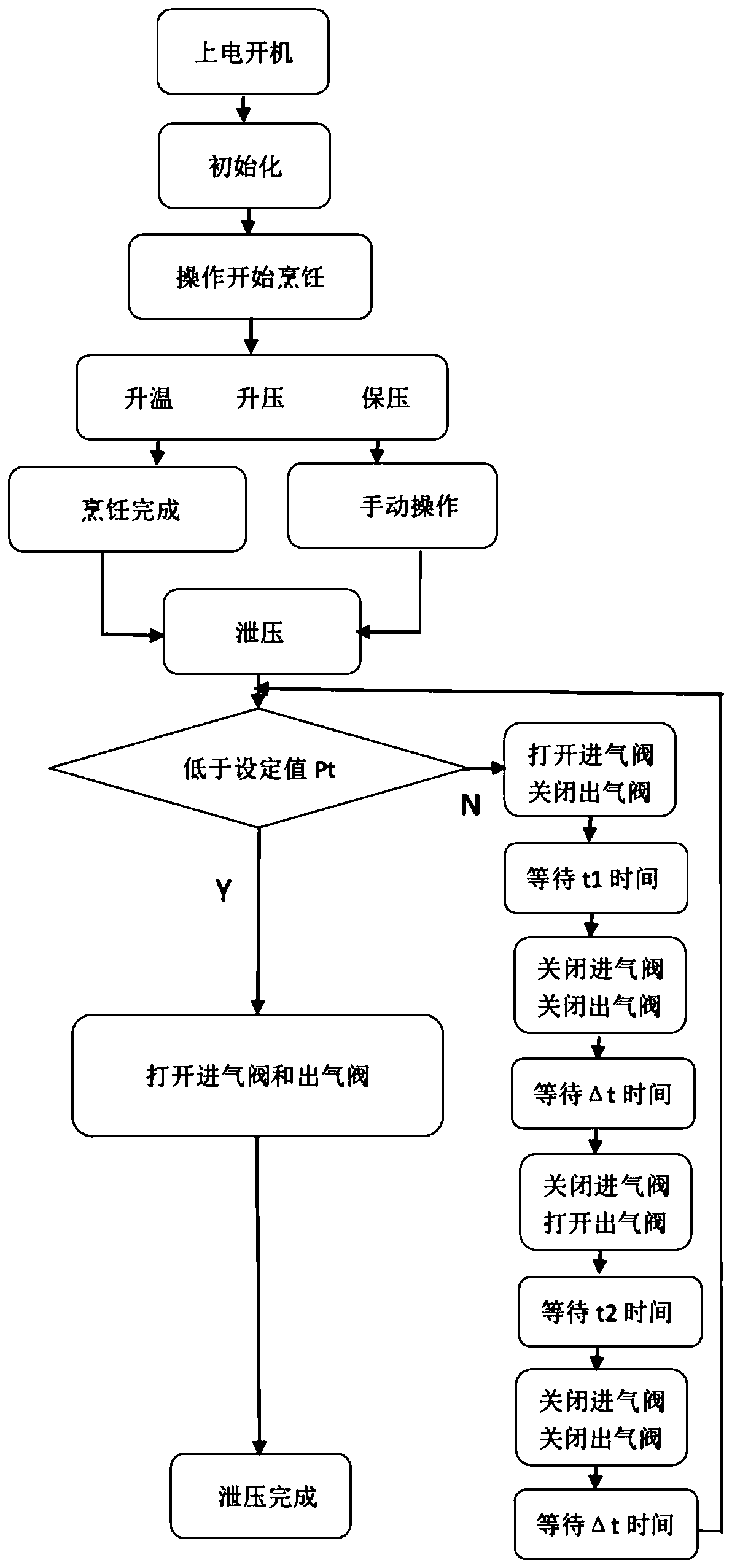

[0043] The present invention is described in detail below with reference to accompanying drawing and embodiment:

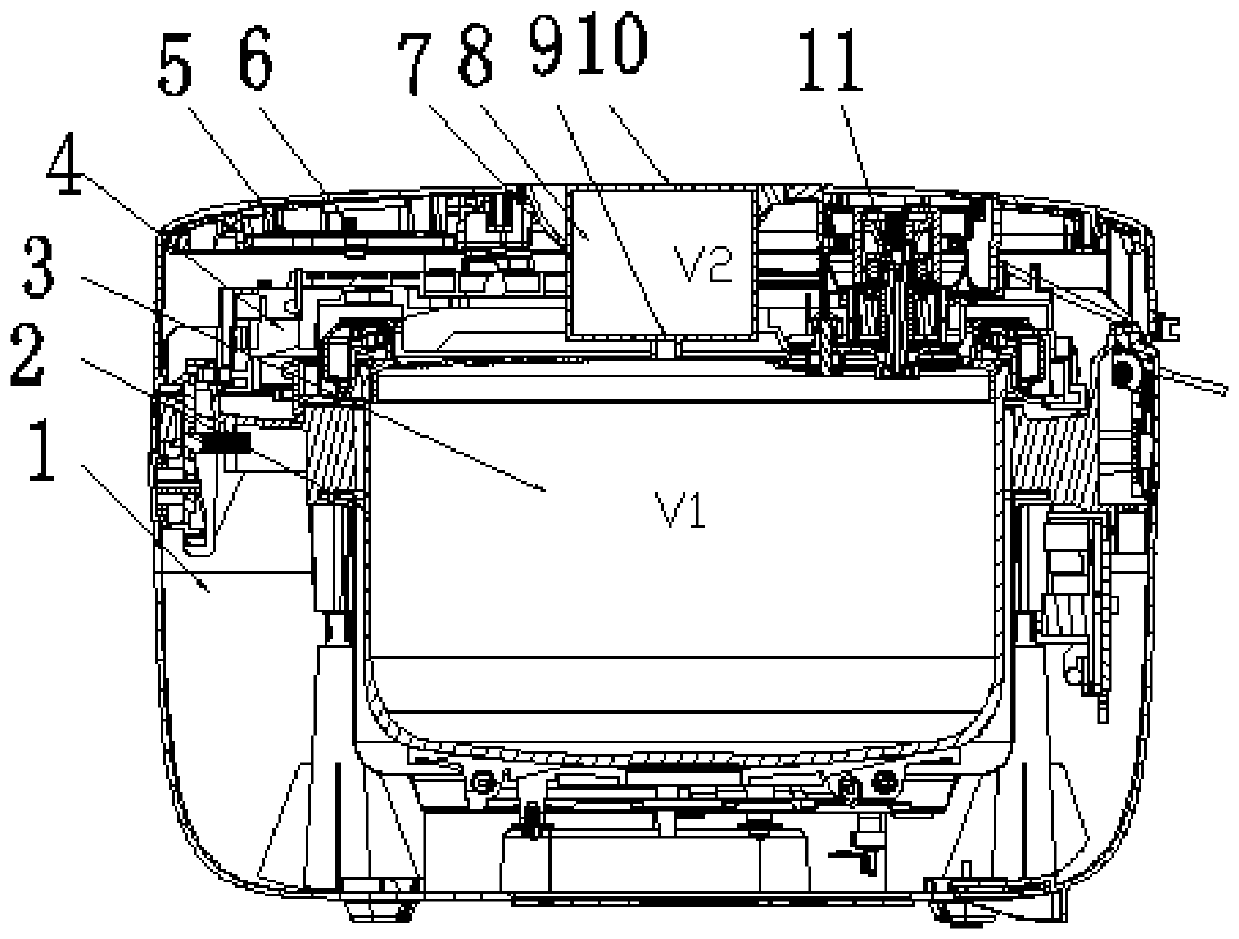

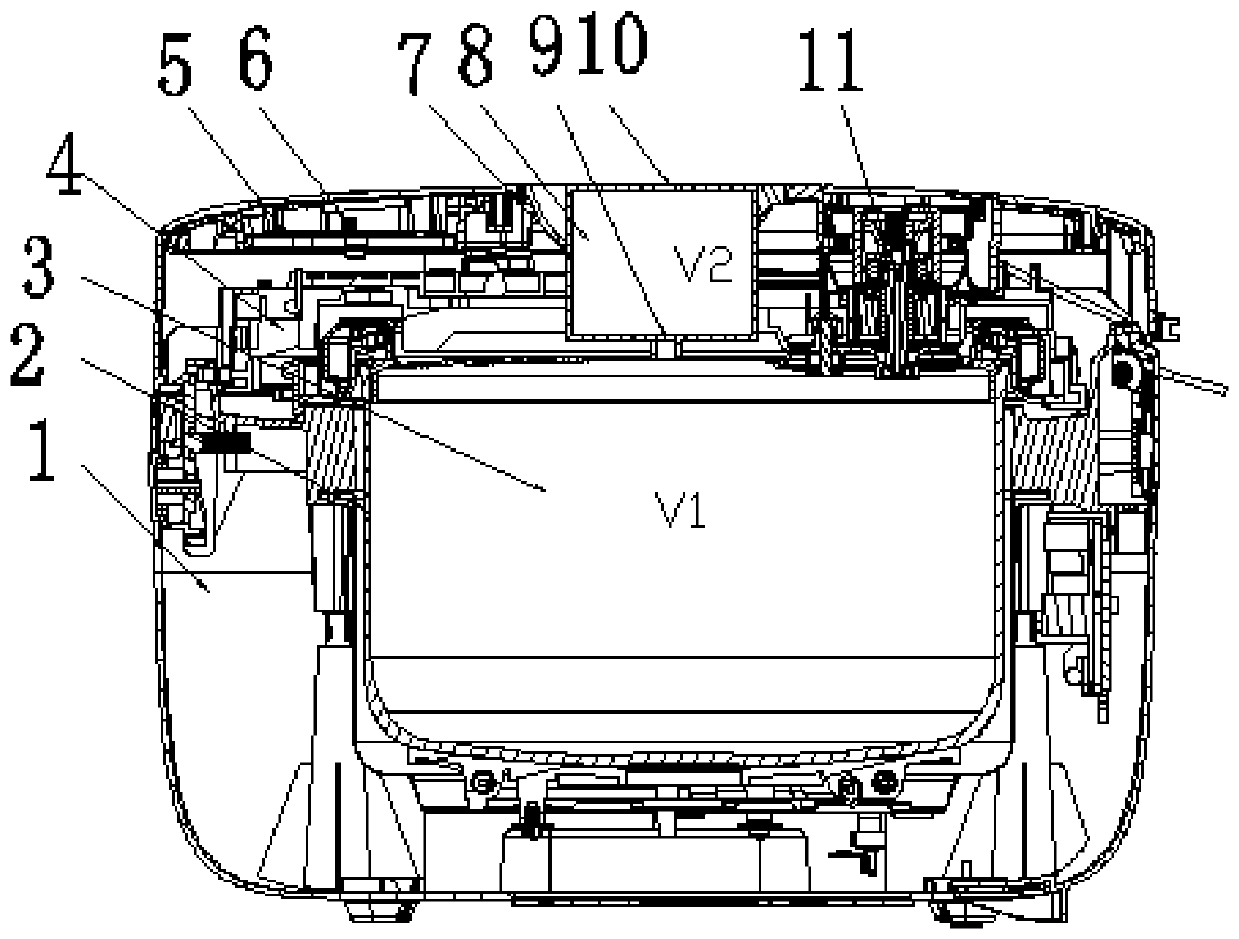

[0044] attached Figure 1-2 It can be seen that a rapid pressure relief mechanism for an electric pressure cooker includes a pot body 1 and a cover body 4; the pot body 1 is provided with an inner pot 2 for containing food materials, and the cover body 4 covers the upper part of the pot body 1 to seal the inner pot 2 The pot body 1 is provided with a micro-control unit MCU6 for controlling the work of the electric pressure cooker, the cover body 4 is provided with a pressure valve 11 for generating and controlling the pressure value, and the cover body 4 is provided with a step-by-step pressure relief valve. Pressure relief transfer chamber 7.

[0045] The pressure relief transfer bin is a closed cavity structure;

[0046] The pressure relief transfer bin is provided with an air inlet channel and an air outlet channel;

[0047] The intake channel is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com