Freeze-dried preparation and preparation method and applications thereof

A freeze-dried preparation and freeze-drying technology, applied in biochemical equipment and methods, freeze-dried delivery, skin care preparations, etc., can solve the problems of limited drug loading, complex structure, disintegration and poor dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

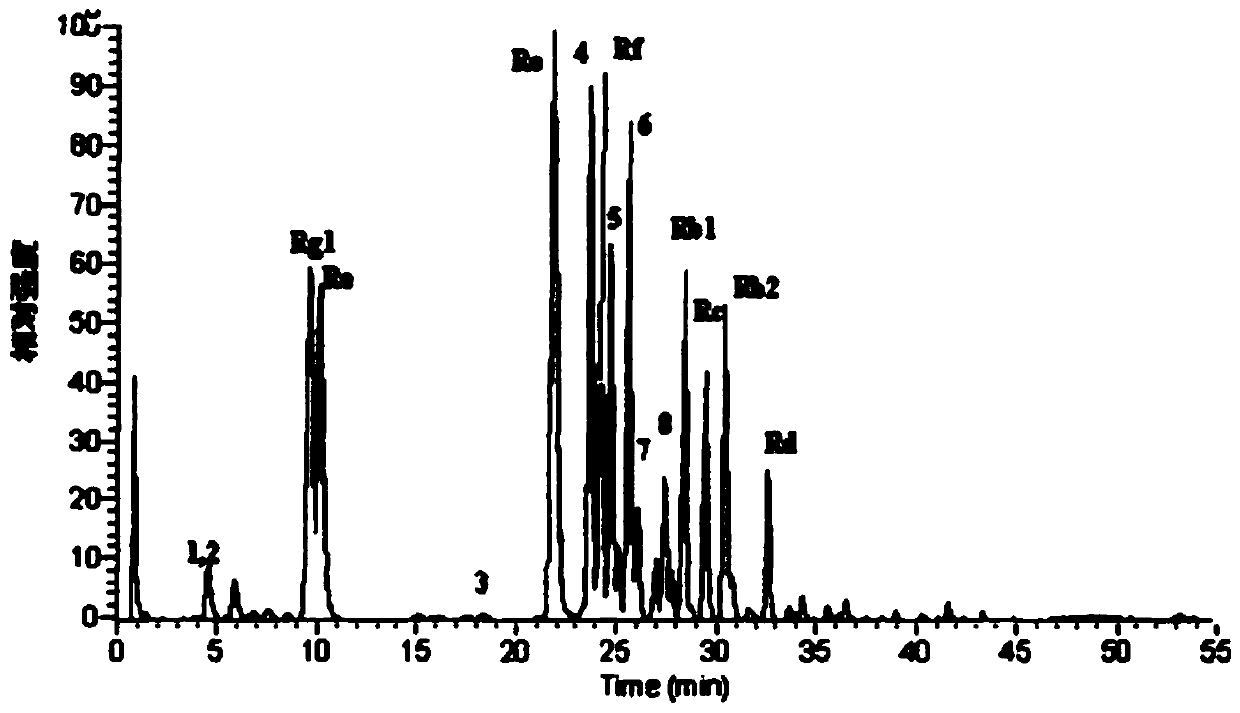

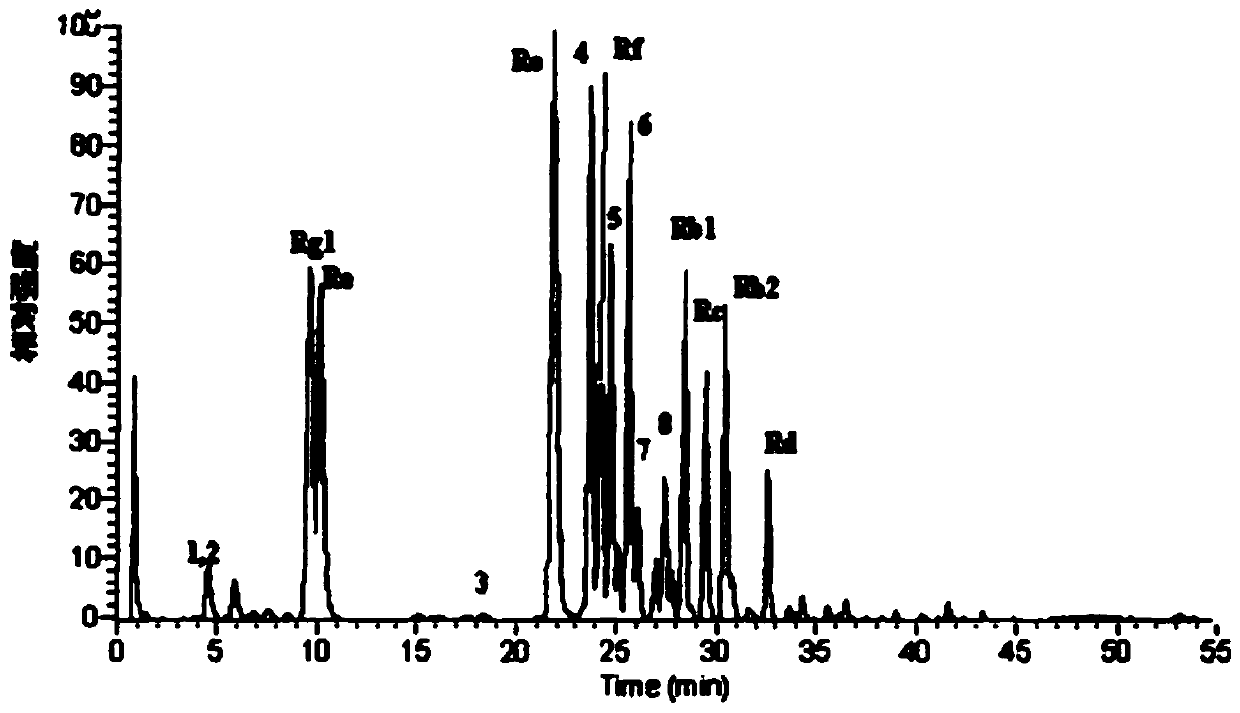

Image

Examples

Embodiment 1

[0135] A freeze-dried preparation, which is used as an oral preparation, the triterpene saponin in the freeze-dried preparation is malonyl ginsenoside Re, and its percentage content is 10%, the binder is pullulanase polysaccharide, and its The percentage content is 3%.

[0136] The freeze-dried preparation is prepared through the following steps:

[0137] a) After mixing water, malonyl ginsenoside Re and pullulanase polysaccharide to form a pre-preparation solution, constant volume and degassing;

[0138] b) Using a quantitative filling pump, inject the pre-dosing solution obtained in a) into a 1ml sheet-shaped molding mold for degassing;

[0139] c) freeze-drying the side product obtained in b), and removing the solvent to obtain an oral freeze-dried preparation.

[0140] The oral preparation has the function of lowering blood sugar, the disintegration time is within 3s, and the dissolution rate is 95% within 30s. In this example, malonyl ginsenoside Re was replaced with oth...

Embodiment 2

[0143] A freeze-dried preparation, which is used as an oral preparation, the triterpenoid saponins in the freeze-dried preparation are 10% malonyl ginsenoside Rg1 and 20% malonyl ginsenoside Rb1, the total is 30%, and the binder It is guar gum (0.5%) and butylene glycol (15%); the auxiliary material is a skeleton support agent (modified tapioca starch), and its percentage is 5%. The disintegration time of the oral preparation is within 3s, and the dissolution rate is 95% within 30s.

[0144] The freeze-dried preparation is prepared through the following steps:

[0145] a) Preparation of soft ice mixture: mix malonyl ginsenoside Rg1 and malonyl ginsenoside Rb1, guar gum and butylene glycol with water according to a set ratio to obtain a pre-preparation solution, and freeze the pre-preparation solution to obtain soft ice mix 1;

[0146] b) Use a spherical mold with a specification of 0.6ml to shape the shape, obtain the shaped mixture 2, and demould;

[0147] c) Freeze-drying...

Embodiment 3

[0151] A kind of freeze-dried preparation, this freeze-dried preparation is used as oral preparation, and triterpene saponin is platycodon saponin E30% in this freeze-dried preparation, and binding agent is modified starch (percentage content is 30%); Adjuvant is antioxidant ( Vitamin C, its percentage content is 7%), and active ingredient is ginseng polysaccharide (percentage content is 5%). The disintegration time of the oral preparation is within 3s, and the dissolution rate is 90% within 50s.

[0152] The freeze-dried preparation is prepared through the following steps:

[0153] a) Preparation of soft ice mixture: mixing platycodon saponin E, modified starch, vitamin C and water according to a set ratio to obtain a pre-preparation liquid, freezing the pre-preparation liquid to obtain a soft ice mixture;

[0154] b) using ginseng polysaccharide as dry powder;

[0155] e) mixing soft ice mixture and ice powder to obtain all soft ice mixtures;

[0156] f) use an ellipsoida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com